Are you gearing up for a career in Bottoming Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Bottoming Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

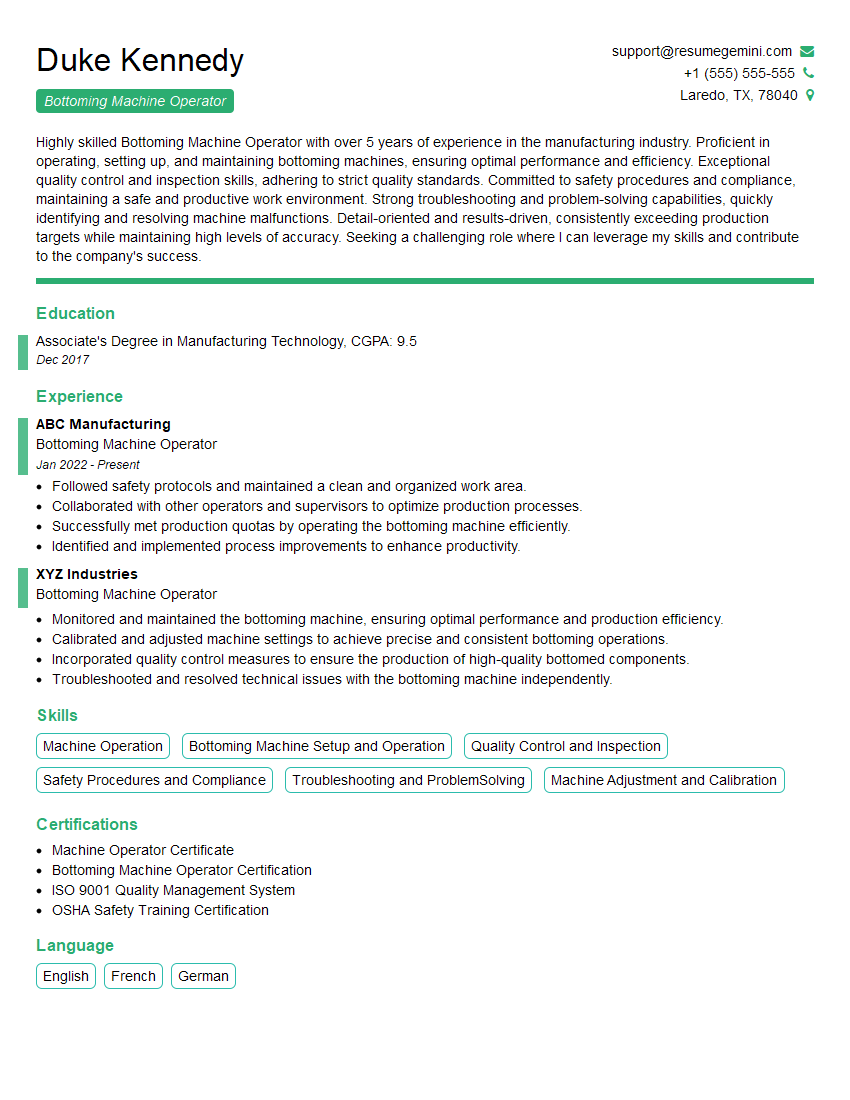

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bottoming Machine Operator

1. Explain the process of setting up a bottoming machine for different types of bottles?

Sample answer:

- Identify the type of bottle and gather the necessary tooling.

- Adjust the machine’s settings for the specific bottle size and shape.

- Load the bottles into the machine’s feed conveyor.

- Position the bottoming head over the bottle and engage the conveyor.

- Monitor the machine’s performance and make adjustments as needed to ensure proper bottoming.

2. How do you maintain and troubleshoot a bottoming machine?

Daily Maintenance

- Lubricate moving parts.

- Clean the machine and remove debris.

- Inspect the bottoming head for wear and tear.

Troubleshooting

- Identify the issue and refer to the machine’s manual.

- Check for loose connections or damaged components.

- Perform adjustments or repairs as needed to resolve the issue.

3. What is the importance of proper bottoming for bottles?

Sample answer:

- Ensures the structural integrity of the bottle.

- Facilitates proper labeling and packaging.

- Prevents leakage and spoilage.

- Enhances the overall appearance of the product.

4. Describe the different types of bottoming machines?

Sample answer:

- Single-head bottoming machines (for small-scale operations).

- Multi-head bottoming machines (for high-volume production).

- Automated bottoming machines (for fully automated operations).

- Semi-automated bottoming machines (for manual loading and automated bottoming).

5. What are the safety precautions that must be observed when operating a bottoming machine?

Sample answer:

- Wear appropriate safety gear (gloves, safety glasses).

- Keep hands clear of moving parts.

- Follow the manufacturer’s operating instructions.

- Ensure the machine is properly grounded.

- Report any safety concerns or malfunctioning equipment promptly.

6. How do you optimize the efficiency of a bottoming machine?

Sample answer:

- Proper maintenance and lubrication.

- Regular cleaning and removal of debris.

- Optimizing the machine’s settings for different bottle types.

- Utilizing automated feeding systems.

- Training operators on efficient operating practices.

7. Describe your experience in setting up and operating bottoming machines.

Sample answer:

- Experience setting up and operating various types of bottoming machines.

- Proficient in adjusting machine settings and optimizing performance.

- Experience in troubleshooting and resolving machine malfunctions.

- Strong attention to detail and commitment to quality control.

8. How do you ensure the quality of bottomed bottles?

Sample answer:

- Regular visual inspection of bottomed bottles.

- Monitoring machine parameters to ensure proper operation.

- Periodic testing of bottles to verify structural integrity.

- Implementing quality control measures and corrective actions as needed.

9. What are the challenges you have encountered in operating bottoming machines?

Sample answer:

- Dealing with different bottle sizes and shapes.

- Resolving machine malfunctions and production issues.

- Maintaining high levels of productivity while ensuring quality.

- Keeping up with advancements in bottoming machine technology.

10. Why are you interested in this Bottoming Machine Operator position?

Sample answer:

- Passion for manufacturing and precision engineering.

- Experience and desire to optimize production efficiency.

- Commitment to delivering high-quality products.

- Eagerness to contribute to the success of your company.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bottoming Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bottoming Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bottoming Machine Operators play a crucial role in the manufacturing process, ensuring the smooth operation of bottoming machines and the production of high-quality products.

1. Machine Operation

Operate bottoming machines with accuracy and efficiency, following established procedures and safety protocols.

- Set up and calibrate machines according to specifications, ensuring optimal performance.

- Monitor machine functions, including speed, temperature, and pressure, and adjust settings as needed.

2. Material Handling

Handle and load raw materials and finished products with care and precision, ensuring proper placement and alignment.

- Inspect materials for defects and damage, rejecting or replacing faulty items as necessary.

- Unload finished products from machines and stack them neatly, adhering to quality standards.

3. Product Inspection

Visually inspect finished products for any defects or inconsistencies, ensuring adherence to specifications.

- Identify and categorize defects according to established quality criteria, reporting any non-conforming items.

- Work with quality control personnel to resolve production issues and implement corrective actions.

4. Maintenance and Repair

Perform basic maintenance tasks, such as cleaning, lubrication, and minor repairs, to ensure machine uptime.

- Identify and report any machine malfunctions or defects promptly to designated personnel.

- Assist with troubleshooting and repair operations as directed by supervisors.

Interview Tips

Preparing thoroughly for an interview can significantly enhance your chances of success. Here are some tips and hacks to help you ace your interview for the Bottoming Machine Operator position:

1. Research the Company and Position

Demonstrate your interest and enthusiasm by researching the company, its products, and the specific requirements of the Bottoming Machine Operator position.

- Visit the company’s website and read about their history, mission, and values.

- Identify the key responsibilities and qualifications for the position, as outlined in the job description.

2. Highlight Relevant Skills and Experience

Focus on showcasing your skills and experience that are directly relevant to the job. Quantify your accomplishments and provide specific examples to illustrate your abilities.

- Emphasize your experience operating bottoming machines, including the types of machines you have worked with.

- Share examples of how you have ensured product quality through effective inspection techniques.

3. Practice Common Interview Questions

Prepare for common interview questions by practicing your answers beforehand. This will help you feel more confident and articulate during the interview.

- Practice answering questions about your motivation for applying to the position.

- Prepare to discuss your strengths and weaknesses as they relate to the role of a Bottoming Machine Operator.

4. Show Enthusiasm and Professionalism

Convey your enthusiasm for the position and the company. Dress professionally and arrive on time for your interview.

- Greet the interviewer with a firm handshake and make eye contact.

- Thank the interviewer for their time and consideration, and reiterate your interest in the position.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Bottoming Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Bottoming Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.