Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Broke Beater Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Broke Beater Operator so you can tailor your answers to impress potential employers.

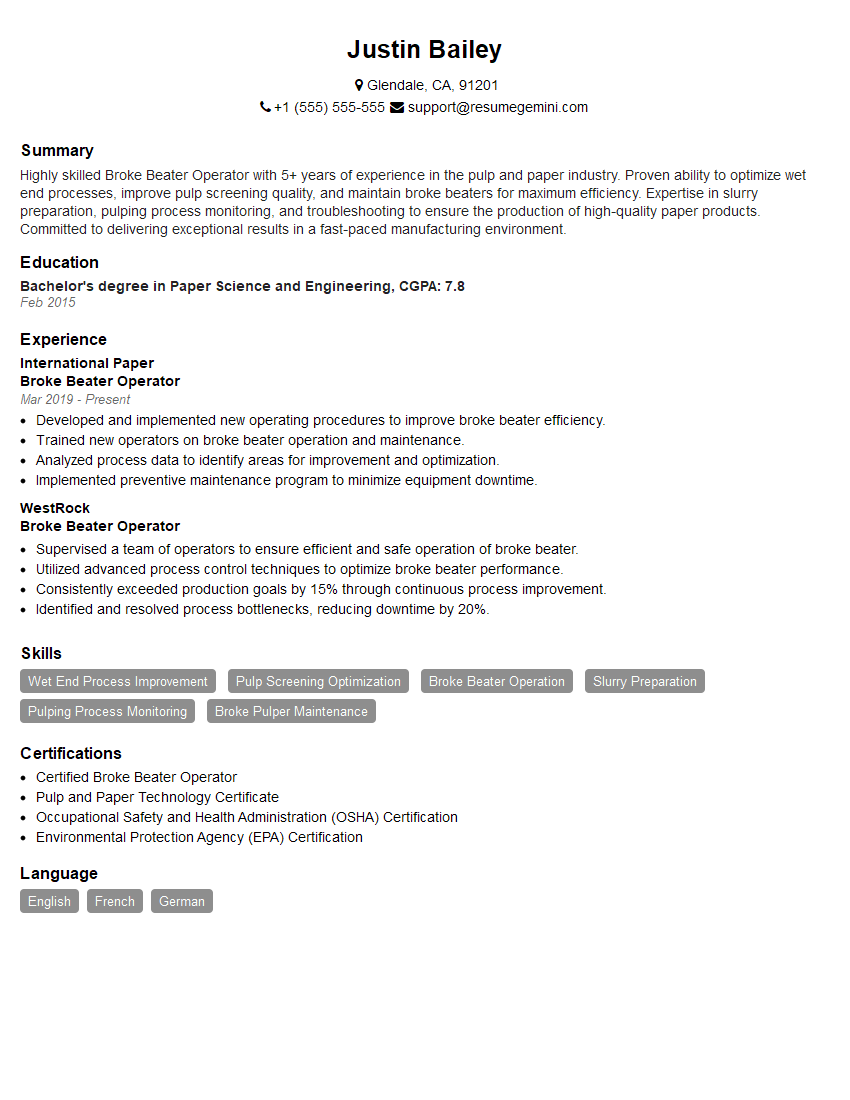

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Broke Beater Operator

1. How do you ensure the optimal performance of a broke beater?

To ensure optimal performance, I conduct regular inspections and maintenance tasks, including:

- Checking belt tension, alignment, and lubrication

- Inspecting blades for wear or damage

- Cleaning and greasing bearings

- Monitoring vibration levels

2. What safety precautions do you take when operating a broke beater?

Safe Operation Practices

- Wearing appropriate PPE (gloves, safety glasses, earplugs)

- Ensuring guards and enclosures are in place

- Maintaining a clean and organized work area

Emergency Procedures

- Knowing the location of emergency stop buttons

- Following proper lockout/tagout procedures

- Being trained on emergency response plans

3. Explain the process of adjusting the bedplate gap in a broke beater.

To adjust the bedplate gap:

- Loosen the locking bolts on the bedplate

- Use feeler gauges to measure the gap between the bedplate and beater roll

- Adjust the set screws on the bedplate until the desired gap is achieved

- Tighten the locking bolts to secure the bedplate

- Re-check the gap with feeler gauges to ensure accuracy

4. Describe how you troubleshoot a broke beater that is not producing the desired pulp consistency.

I follow a systematic troubleshooting process:

- Check the feed rate and consistency of the incoming pulp

- Inspect the blades for wear or damage

- Check the bedplate gap and adjust if necessary

- Monitor the temperature of the pulp and adjust cooling water if needed

- Ensure the broke beater is running at the correct speed

5. How do you maintain the quality of the pulp produced by a broke beater?

I maintain pulp quality by:

- Controlling the feed rate and consistency

- Adjusting the bedplate gap to optimize fiber length

- Monitoring the temperature of the pulp

- Inspecting and replacing worn or damaged blades

- Performing regular maintenance and calibration

6. Describe the role of the beater roll in a broke beater.

The beater roll rotates and contacts the bedplate, breaking down the pulp fibers:

- Fibers are subjected to mechanical forces, causing them to swell and soften

- The beater roll’s shape and speed determine the degree of fiber hydration

- Proper maintenance of the beater roll, including blade sharpness and bedplate gap, is crucial for optimal performance

7. How do you calculate the production capacity of a broke beater?

I calculate production capacity using the following formula:

Capacity = (Feed Rate * Consistency) / Density

where:- Capacity is in tons per hour

- Feed Rate is in gallons per minute

- Consistency is in percent

- Density is in pounds per cubic foot

8. What is the difference between a broke beater and a refiner?

While both broke beaters and refiners are used in pulp processing, they have distinct functions:

- Broke beater: Pulps broke (recycled paper) to recover fibers

- Refiner: Further processes pulp to reduce fiber length and improve its properties

- Broke beaters typically have beater rolls with blunt blades, while refiners have disc-type blades

9. Explain the importance of proper lubrication in a broke beater.

Proper lubrication is essential for the smooth operation and longevity of a broke beater:

- Reduces friction and wear on bearings and gears

- Prevents overheating and premature failure

- Improves efficiency and power consumption

- Regular greasing and oil changes should be part of a maintenance schedule

10. How do you handle process deviations or equipment malfunctions while operating a broke beater?

When process deviations or equipment malfunctions occur, I follow these steps:

- Identify the issue and its potential cause

- Isolate the problem and take necessary safety precautions

- Consult with maintenance personnel or supervisors for troubleshooting and repair assistance

- Monitor the situation closely and document the event

- Once the issue is resolved, resume operation and optimize process parameters

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Broke Beater Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Broke Beater Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Broke Beater Operator plays a pivotal role in pulp making processes. Their core responsibilities encompass:

1. Machine Operation and Maintenance

Ensuring smooth and efficient operation of the broke beater machine, including monitoring and adjusting machine parameters.

- Conducting routine inspections and preventive maintenance to minimize downtime and ensure optimal performance.

- Addressing minor mechanical issues and reporting major ones to designated personnel for prompt resolution.

2. Broke Slurry Processing

Handling and processing broke slurry, a mixture of waste paper and water, to prepare it for re-use in papermaking.

- Feeding broke slurry into the broke beater machine and monitoring its consistency and quality.

- Adjusting machine settings to achieve desired consistency and fiber characteristics for re-use.

3. Quality Control and Monitoring

Maintaining the quality of the processed broke slurry and adhering to established quality standards.

- Conducting regular checks on the broke slurry’s consistency, pH, and other key indicators.

- Making necessary adjustments to maintain consistent quality and minimize variation.

4. Safety and Environmental Compliance

Adhering to safety protocols and ensuring compliance with environmental regulations.

- Performing tasks in a safe manner, following established guidelines and procedures.

- Monitoring and reporting on environmental parameters to ensure compliance with regulations.

Interview Tips

To ace an interview for a Broke Beater Operator position, consider the following preparation tips:

1. Research the Company and Industry

Thoroughly research the company and the pulp and paper industry to demonstrate your interest and understanding.

- Familiarize yourself with the company’s products, operations, and market position.

- Stay up-to-date on industry trends and technological advancements.

2. Highlight Relevant Experience and Skills

Emphasize your experience in operating and maintaining machinery, as well as your skills in quality control and process optimization.

- Quantify your accomplishments with specific examples and data whenever possible.

- Explain how your skills and experience align with the job requirements and add value to the organization.

3. Prepare for Technical Questions

Be prepared to answer technical questions about broke beater machine operation, slurry processing, and quality control procedures.

- Review common operating principles and troubleshooting techniques.

- Understand the process of broke slurry preparation and the factors that affect its quality.

4. Showcase Safety Awareness and Environmental Consciousness

Demonstrate your commitment to safety and environmental compliance by highlighting relevant experience and practices.

- Describe your understanding of safety protocols and your commitment to following them.

- Explain how you have contributed to environmental sustainability in previous roles.

5. Practice and Seek Feedback

Practice answering interview questions out loud and seek feedback from a trusted mentor or friend.

- Identify areas where you need improvement and work on enhancing your responses.

- Practice delivering your answers confidently and clearly.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Broke Beater Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Broke Beater Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.