Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Calender Let-Off Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

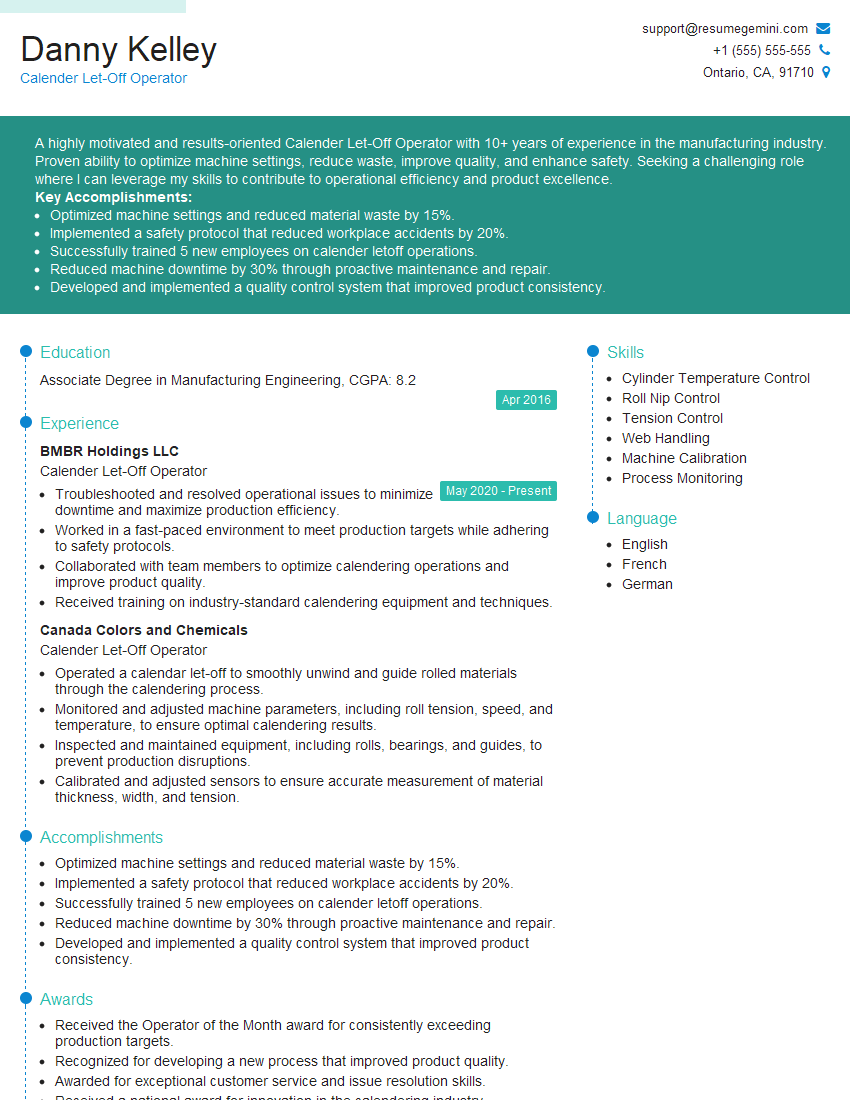

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Calender Let-Off Operator

1. Describe your understanding of the role of a Calender Let-Off Operator?

As a Calender Let-Off Operator, my primary responsibility is to ensure the smooth and efficient operation of the calender machine by controlling the let-off of fabric or film. I am responsible for monitoring and adjusting machine settings to maintain optimal tension and alignment of the material throughout the calendaring process.

2. Explain the key principles of calendering and how they impact your role as a Let-Off Operator.

Material Preparation

- Prepare the fabric or film by inspecting it for defects and ensuring its proper alignment before feeding it into the machine.

Calendering Process

- Monitor and adjust the machine’s speed, tension, and temperature settings to achieve the desired properties of the material, such as thickness, smoothness, and surface finish.

Post-Calendering

- Inspect the finished product to ensure it meets quality standards and prepare it for further processing or storage.

3. Describe the different types of calenders and their specific applications.

- Friction Calender: Used to reduce the thickness and improve the surface finish of fabrics.

- Embossing Calender: Creates patterns or designs on the fabric or film by using engraved rollers.

- Laminating Calender: Bonds multiple layers of material together, such as fabric and film.

- Coating Calender: Applies a coating to the surface of the material, such as a protective layer or adhesive.

4. Explain the importance of maintaining proper tension control during the calendaring process.

- Material Quality: Excessive or insufficient tension can cause defects, such as tearing, stretching, or wrinkles.

- Machine Efficiency: Maintaining optimal tension ensures smooth material flow and prevents machine stoppages.

- Product Consistency: Consistent tension control results in uniform thickness and surface finish throughout the entire length of the material.

5. Describe the troubleshooting procedures you follow when encountering common problems during the calendaring process.

- Wrinkling: Adjust tension settings or inspect the material for defects.

- Stretching: Reduce machine speed or adjust tension settings.

- Tearing: Inspect the material for weak spots or adjust tension and speed settings.

- Rollers sticking: Clean the rollers or adjust the machine’s temperature settings.

6. Explain the safety precautions you observe while operating a calender machine.

- Wear appropriate safety gear, such as gloves and eye protection.

- Keep the work area clean and free of tripping hazards.

- Follow lockout/tagout procedures when performing maintenance.

- Be aware of pinch points and sharp edges.

- Report any unsafe conditions or equipment malfunctions immediately.

7. Describe the importance of good communication and teamwork in the calendering operation.

- Coordination: Effective communication ensures smooth coordination among team members, especially during shift changes.

- Problem-Solving: Sharing knowledge and ideas helps in troubleshooting and resolving issues quickly.

- Safety: Clear communication prevents accidents and ensures the safety of everyone involved.

8. Explain how you handle high-pressure situations and meet production targets.

- Prioritize Tasks: Identify the most important tasks and allocate resources accordingly.

- Communicate Effectively: Keep supervisors and team members informed about progress and any challenges faced.

- Stay Calm: Maintain composure and focus on finding solutions even in stressful situations.

- Work Efficiently: Optimize processes and reduce downtime to maximize productivity.

9. Describe your experience in working with different types of materials on a calender machine.

- Fabrics: Cotton, polyester, silk, nylon, etc.

- Films: Plastic, metalized, etc.

- Composite Materials: Combinations of fabrics, films, and adhesives.

Explain how you adjusted machine settings and techniques to accommodate the different material properties.

10. How do you stay updated with the latest advancements in calendering technology?

- Industry Publications: Read trade journals and attend conferences.

- Manufacturer’s Training: Participate in training programs offered by equipment manufacturers.

- Online Resources: Utilize online forums, webinars, and technical articles.

- Networking: Connect with other professionals in the field and exchange knowledge.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Calender Let-Off Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Calender Let-Off Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Calender Let-Off Operators play a crucial role in rubber and plastics manufacturing, ensuring the smooth operation of calendering machines. Their key responsibilities encompass the following:

1. Machine Operation

Operate calendering machines to process rubber or plastic compounds into sheets or films.

- Monitor machine settings, such as temperature, pressure, and speed.

- Adjust controls to optimize production and maintain product quality.

2. Material Handling

Handle raw materials and finished products, ensuring proper storage and handling procedures.

- Load and unload materials from the machine.

- Inspect finished products for defects.

3. Quality Control

Monitor the quality of processed materials, ensuring adherence to specifications.

- Perform quality checks on materials before and after calendering.

- Identify and resolve quality issues promptly.

4. Maintenance and Troubleshooting

Perform basic maintenance and troubleshooting tasks to keep the machine in optimal condition.

- Lubricate and clean the machine regularly.

- Identify and resolve minor malfunctions.

Interview Tips

To ace the interview for a Calender Let-Off Operator position, candidates should consider the following tips:

1. Research the Company and Industry

Demonstrate your interest in the company and the industry by researching their products, services, and recent developments.

- Visit the company’s website and social media pages.

- Read articles and industry publications to stay informed.

2. Highlight Your Technical Skills

Emphasize your technical skills and knowledge in calendering operations. Provide specific examples of your experience.

- Describe your proficiency in operating and maintaining calendering machines.

- Share your knowledge of different materials and their properties.

3. Showcase Your Quality-Focused Approach

Convey your commitment to quality control and attention to detail. Highlight your ability to identify and resolve quality issues.

- Explain your experience in conducting quality checks and implementing corrective actions.

- Provide examples of how you improved product quality.

4. Emphasize Your Teamwork and Communication Skills

Discuss your ability to work effectively as part of a team and communicate clearly with colleagues and supervisors.

- Describe your experience working in a team environment and collaborating on projects.

- Share examples of how you effectively communicated with others.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Calender Let-Off Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Calender Let-Off Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.