Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Calendering Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

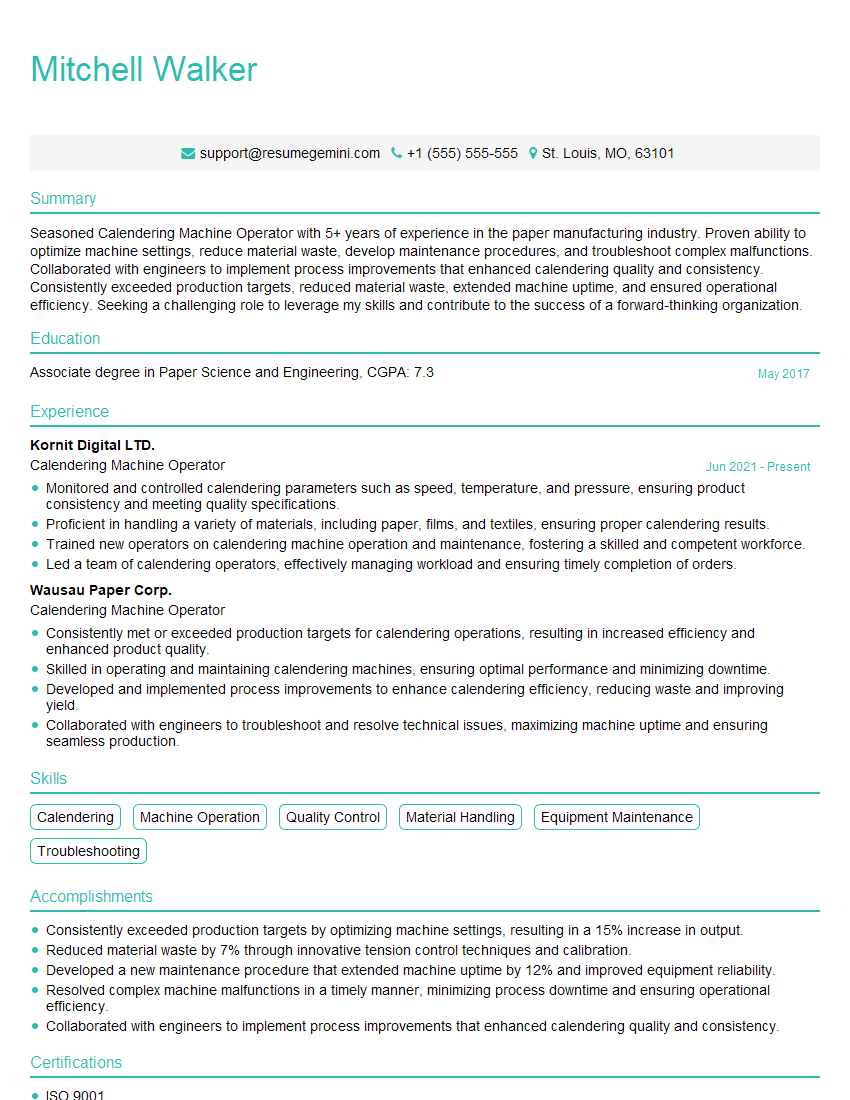

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Calendering Machine Operator

1. Describe the key responsibilities of a Calendering Machine Operator?

- Operate and maintain a calendaring machine to process rubber or plastic materials.

- Follow production schedules and maintain quality standards.

- Inspect materials before and after processing to ensure quality and identify defects.

- Make adjustments to the machine as needed to ensure optimal performance and minimize waste.

- Clean and maintain the machine and work area to ensure safety and prevent contamination.

2. Explain the process of calendering and its importance in rubber and plastic manufacturing?

- Calendering is a process of passing a material through heated rollers to reduce its thickness and produce a desired finish.

- It is essential in the manufacturing of rubber and plastic products as it improves the uniformity, smoothness, and properties of the material.

- Calendering can be used to create a variety of textures, patterns, and colors on the surface of the material.

3. What are the different types of calendering machines and their specific applications?

- There are various types of calendering machines, each designed for specific applications.

- Two-roll calenders: Used for simple sheeting and coating operations.

- Three-roll calenders: Provide better control over thickness and surface finish.

- Four-roll calenders: Used for high-precision applications and multiple-layer laminating.

- Inverted “L” calenders: Allow for the production of thin and delicate films.

4. How do you control the thickness and surface finish of the calendared material?

- The thickness is controlled by adjusting the distance between the rollers.

- The surface finish is influenced by the temperature, speed, and pressure of the rollers.

- Additional factors such as the type of material and the use of release agents can also affect the surface finish.

5. Describe the common defects that can occur during calendering and how to prevent them?

- Wrinkles: Caused by uneven feeding or incorrect roller alignment.

- Bubbles: Result from trapped air or moisture in the material.

- Scratches: Caused by foreign objects or damaged rollers.

- Edge tears: Occur due to excessive tension or uneven pressure.

- Preventing defects involves proper machine setup, careful material handling, and regular maintenance.

6. How do you ensure the safety of yourself and others while operating a calendering machine?

- Wear appropriate safety gear, including earplugs, gloves, and safety glasses.

- Keep the work area clean and free of tripping hazards.

- Never reach into the machine while it is operating.

- Follow proper lockout/tagout procedures when performing maintenance.

- Be aware of the potential for nip points and hot surfaces.

7. What are the preventive maintenance tasks that you perform to keep the calendering machine in optimal condition?

- Regularly inspect and clean the machine, including the rollers, bearings, and gears.

- Lubricate all moving parts according to the manufacturer’s recommendations.

- Check and adjust the tension of the belts and chains.

- Monitor the temperature of the rollers and make adjustments as needed.

- Perform scheduled overhauls to replace worn parts and ensure the machine’s reliability.

8. How do you troubleshoot common problems that may arise with a calendering machine?

- Identify the problem and its potential causes.

- Check the machine’s settings and make adjustments as necessary.

- Inspect the material for defects or contamination.

- Consult the machine’s manual or seek guidance from a supervisor or technician.

- If the problem persists, seek professional assistance.

9. What is your experience with different types of calendering machines?

Describe your experience with various calendering machines, including their capabilities and limitations.

- Two-roll calenders: Experience in operating two-roll calenders for sheeting and coating applications.

- Three-roll calenders: Hands-on experience with three-roll calenders for precise thickness control and surface finishing.

- Four-roll calenders: Familiarity with four-roll calenders for multi-layer laminating and high-precision operations.

- Inverted “L” calenders: Knowledge of the operation and applications of inverted “L” calenders for thin film production.

10. How do you stay updated with the latest advancements in calendering technology?

- Attend industry conferences and exhibitions.

- Read trade journals and technical publications.

- Participate in online forums and discussions.

- Consult with experts in the field.

- Stay informed about new machine designs, materials, and process innovations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Calendering Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Calendering Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Calendering Machine Operators play a crucial role in manufacturing processes. They are responsible for operating and monitoring calendering machines, which shape and finish a variety of materials. Key responsibilities include:

1. Machine Operation

The operator is responsible for the safe and efficient operation of the calendering machine. This includes setting up the machine, feeding materials, and monitoring the process.

- Set up and operate calendering machines to process materials according to specifications

- Monitor machine performance, make adjustments, and identify potential problems

2. Material Inspection

The operator must inspect raw materials and finished products to ensure they meet quality standards. They must also be able to identify and correct defects.

- Inspect raw materials to ensure they meet specifications and are suitable for processing

- Inspect finished products to identify defects and ensure they meet quality standards

3. Machine Maintenance

The operator is responsible for performing basic maintenance on the calendering machine. This includes cleaning, lubricating, and replacing worn parts.

- Perform basic maintenance and repairs on the calendering machine

- Monitor machine performance and identify potential problems

4. Safety

The operator must follow all safety procedures and wear appropriate personal protective equipment. They must also be able to identify and avoid potential hazards.

- Follow all safety procedures and wear appropriate personal protective equipment

- Identify and avoid potential hazards

Interview Tips

To ace the interview for a Calendering Machine Operator position, candidates should prepare themselves by:

1. Researching the Company

Understanding the company’s mission, values, and products will help you tailor your answers to the interviewer’s questions. It also shows that you are genuinely interested in the position.

- Visit the company’s website and read its mission statement, values, and product descriptions

- Research the company’s history, size, and industry

- Check the company’s social media pages to learn about its culture and recent news

2. Practicing Answers to Common Interview Questions

There are a few common interview questions that you are likely to encounter. By practicing your answers to these questions, you can increase your confidence and deliver a more polished response.

- Why are you interested in this position?

- Tell me about your experience in operating calendering machines.

- What are your strengths and weaknesses?

- What are your salary expectations?

3. Asking Questions About the Position

Asking thoughtful questions about the position shows that you are interested in the job and that you have done your research. It also gives you an opportunity to clarify any details about the job.

- What are the specific responsibilities of this position?

- What is the company’s safety record?

- What are the opportunities for advancement?

4. Dressing Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothing and shoes that are appropriate for a business setting.

- Choose clothing that is comfortable and allows you to move around easily

- Avoid wearing clothing that is too revealing or too casual

- Make sure your shoes are clean and polished

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Calendering Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Calendering Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.