Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Can Sterilizer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Can Sterilizer so you can tailor your answers to impress potential employers.

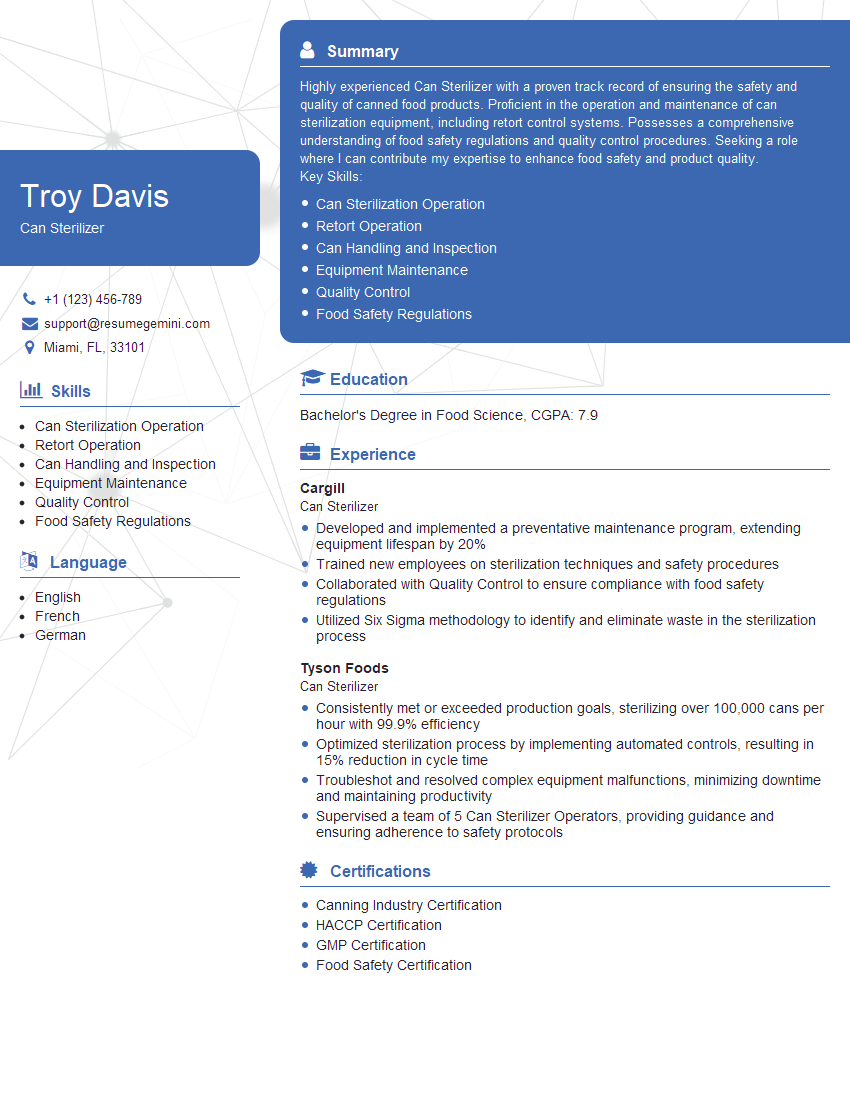

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Can Sterilizer

1. What are the different types of can sterilisers and their uses?

There are two main types of can sterilisers: retort sterilisers and autoclaves.

- Retort sterilisers use hot water or steam to sterilise cans. They are typically used for low-acid foods, such as vegetables and fruits.

- Autoclaves use high-pressure steam to sterilise cans. They are typically used for high-acid foods, such as tomatoes and pickles.

2. What are the critical parameters that need to be controlled during the sterilisation process?

Temperature

- The temperature of the sterilisation medium (water, steam, or air) must be high enough to kill all microorganisms present on the cans and their contents.

- The temperature must be maintained for a sufficient period of time to ensure that all microorganisms are killed.

Pressure

- The pressure inside the steriliser must be high enough to prevent cans from bursting.

- The pressure must be maintained for a sufficient period of time to ensure that all microorganisms are killed.

Time

- The sterilisation process must be run for a sufficient period of time to ensure that all microorganisms are killed.

- The time required will vary depending on the temperature, pressure, and type of food being sterilised.

3. What are the potential hazards associated with the sterilisation process and how can they be mitigated?

The potential hazards associated with the sterilisation process include:

- Can bursting: Cans can burst if the pressure inside the steriliser is too high. This can be mitigated by using cans that are strong enough to withstand the pressure and by carefully controlling the pressure during the sterilisation process.

- Microbial contamination: Cans can become contaminated with microorganisms if the sterilisation process is not properly controlled. This can be mitigated by using sterile equipment and by ensuring that the sterilisation process is run for a sufficient period of time.

- Chemical contamination: Cans can become contaminated with chemicals if the sterilisation medium is not properly controlled. This can be mitigated by using a sterile sterilisation medium and by ensuring that the sterilisation process is run for a sufficient period of time.

4. What are the different methods of testing the effectiveness of the sterilisation process?

The effectiveness of the sterilisation process can be tested using a variety of methods, including:

- Biological testing: This involves incubating cans of sterilised food at a temperature that is favourable for the growth of microorganisms. If no microorganisms grow, then the sterilisation process is considered to be effective.

- Chemical testing: This involves testing the sterilised food for the presence of chemicals that are indicative of microbial contamination. If no chemicals are detected, then the sterilisation process is considered to be effective.

- Physical testing: This involves examining the sterilised cans for any signs of damage or contamination. If no damage or contamination is found, then the sterilisation process is considered to be effective.

5. What are the maintenance and calibration requirements for can sterilisers?

Can sterilisers require regular maintenance and calibration to ensure that they are operating properly and safely.

- Maintenance tasks include cleaning the steriliser, checking the seals and gaskets, and inspecting the heating elements.

- Calibration tasks include verifying the temperature and pressure gauges and ensuring that the steriliser is operating within the specified parameters.

6. What are the different types of can sterilisation cycles?

There are two main types of can sterilisation cycles: continuous and batch.

- Continuous cycles: In a continuous cycle, cans are continuously fed into the steriliser and sterilised. This type of cycle is typically used for high-volume production.

- Batch cycles: In a batch cycle, a batch of cans is loaded into the steriliser and sterilised. This type of cycle is typically used for low-volume production.

7. What are the different types of can sterilisation equipment?

There are a variety of different types of can sterilisation equipment available, including:

- Retort sterilisers: Retort sterilisers use hot water or steam to sterilise cans. They are typically used for low-acid foods, such as vegetables and fruits.

- Autoclaves: Autoclaves use high-pressure steam to sterilise cans. They are typically used for high-acid foods, such as tomatoes and pickles.

- Hydrostatic sterilisers: Hydrostatic sterilisers use hot water to sterilise cans. They are typically used for high-acid foods, such as tomatoes and pickles.

- Aseptic sterilisers: Aseptic sterilisers use a combination of heat and chemicals to sterilise cans. They are typically used for low-acid foods, such as vegetables and fruits.

8. What are the advantages and disadvantages of using can sterilisation?

Advantages

- Can sterilisation is a very effective way to kill microorganisms and prevent spoilage.

- Can sterilisation can extend the shelf life of food products.

- Can sterilisation can help to ensure the safety of food products.

Disadvantages

- Can sterilisation can be a relatively expensive process.

- Can sterilisation can affect the taste and texture of food products.

- Can sterilisation can produce harmful chemicals, such as acrylamide.

9. What are the latest trends in can sterilisation technology?

The latest trends in can sterilisation technology include:

- The use of high-pressure processing (HPP) to sterilise food products.

- The use of pulsed electric fields (PEF) to sterilise food products.

- The use of microwave technology to sterilise food products.

10. What are the future challenges of can sterilisation?

The future challenges of can sterilisation include:

- The development of new sterilisation technologies that are more efficient and cost-effective.

- The development of new sterilisation technologies that are more environmentally friendly.

- The development of new sterilisation technologies that can be used to sterilise a wider range of food products.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Can Sterilizer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Can Sterilizer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Can sterilizers play a crucial role in food safety by eliminating harmful microorganisms from metal or plastic containers used for packaging food. Their responsibilities include:

1. Pre-Sterilization Preparation

intro paragraph

- Inspect and prepare cans and lids for sterilization.

- Ensure proper labeling and identification of containers.

2. Sterilization Process

intro paragraph

- Load cans and lids into sterilization chambers.

- Operate and monitor sterilization equipment, ensuring optimal temperature and pressure conditions.

- Record and document sterilization parameters.

3. Post-Sterilization Handling

intro paragraph

- Unload sterilized containers from sterilization chambers.

- Inspect and verify the integrity of sterilized cans and lids.

- Store sterilized containers in designated areas, ensuring proper storage conditions.

4. Equipment Maintenance and Hygiene

intro paragraph

- Conduct routine cleaning and maintenance of sterilization equipment.

- Calibrate and validate sterilization equipment to ensure accuracy and compliance with regulations.

- Maintain a clean and hygienic work environment to prevent contamination.

Interview Tips

Preparing well for an interview can significantly improve your chances of success. Here are some tips to help you ace your interview for a Can Sterilizer position:

1. Research the Company and Role

Familiarize yourself with the company’s background, values, and the specific requirements of the Can Sterilizer role. Understanding the company’s industry, products, and processes will demonstrate your interest and enthusiasm for the position.

- Visit the company’s website and social media pages.

- Look up industry news and articles related to the company.

- Review the job description thoroughly and identify the key skills and qualifications required.

2. Practice Your Answers

Prepare your responses to common interview questions by considering your relevant experiences, skills, and knowledge. Practice answering aloud to gain confidence and fluency. You can use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples that highlight your accomplishments.

- Brainstorm potential questions based on the job description and research.

- Write down your answers and practice delivering them clearly and concisely.

- Ask a friend or family member to do a mock interview with you.

3. Highlight Your Relevant Experience

Emphasize your experience in food safety, sterilization techniques, and equipment handling. Share examples of your involvement in quality control, sanitation, and process improvement initiatives. If you have previous experience in the food packaging or manufacturing industry, be sure to highlight it.

- Quantify your accomplishments whenever possible using specific metrics.

- Explain how your skills and knowledge have contributed to the success of previous projects.

- Relate your experience to the specific responsibilities of the Can Sterilizer role.

4. Demonstrate Your Safety Mindset

Food safety is paramount in any food production facility. Emphasize your understanding of sterilization principles and your commitment to maintaining a safe and hygienic work environment. Share examples of your attention to detail, adherence to safety protocols, and willingness to take proactive measures to prevent contamination.

- Discuss your knowledge of food safety regulations and industry best practices.

- Highlight your ability to work effectively in a fast-paced and demanding environment.

- Explain how you prioritize safety in your daily work routine.

Next Step:

Now that you’re armed with the knowledge of Can Sterilizer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Can Sterilizer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini