Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Casing Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Casing Machine Operator so you can tailor your answers to impress potential employers.

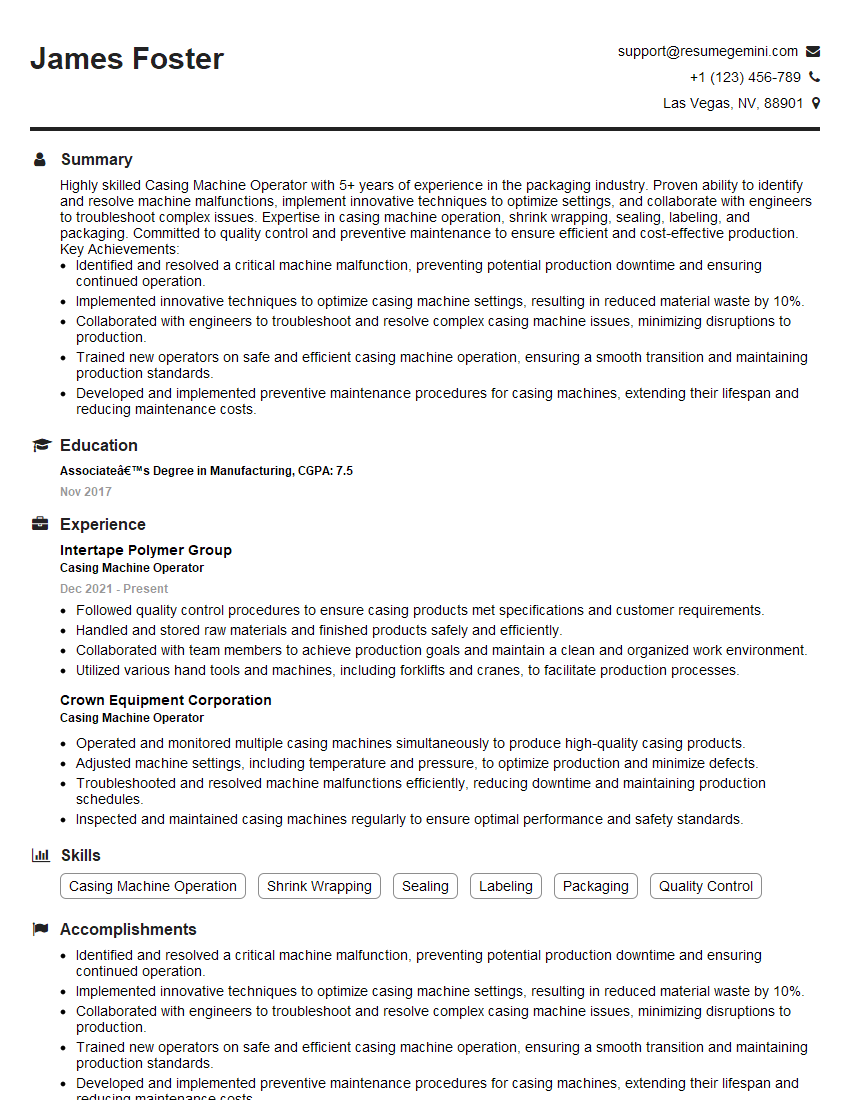

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Casing Machine Operator

1. What are the key responsibilities of a Casing Machine Operator?

As a Casing Machine Operator, my primary responsibilities include:

- Operating and monitoring casing machines to produce high-quality casings

- Setting up, adjusting, and maintaining casing machines to ensure optimal performance

- Inspecting casings for defects and ensuring adherence to quality standards

- Maintaining a clean and safe work environment, following safety protocols

- Collaborating with other team members and supervisors to ensure efficient production

2. Describe the process of setting up and calibrating a casing machine.

Calibration Procedure:

- Securely mount the casing machine in a stable location

- Connect the machine to the appropriate power source and feed materials

- Use precision tools to adjust rollers, guides, and sensors according to specifications

- Run test runs to verify that the machine is producing casings within acceptable tolerances

Setup Process:

- Load the casing material into the machine

- Set the machine speed, temperature, and other parameters

- Inspect the machine for any obstructions or potential hazards

- Start the machine and monitor its performance

3. How do you ensure that casings meet the required specifications?

- Regularly inspect casings during production to check dimensions, wall thickness, and surface finish

- Utilize measuring tools, such as calipers and gauges, to verify that casings meet specifications

- Monitor machine settings and adjust them if necessary to maintain consistency

- Review quality reports and make adjustments to the production process as needed

- Communicate any deviations from specifications to supervisors and take corrective actions

4. What troubleshooting steps do you take if a casing machine malfunctions?

- Identify the source of the malfunction by observing the machine’s operation and error codes

- Check for loose connections, damaged components, or obstructions

- Consult technical manuals and diagrams to diagnose the issue

- Replace or repair faulty components as necessary

- Recalibrate the machine and perform test runs to ensure proper functionality

5. How do you maintain and clean a casing machine to ensure its longevity?

- Clean the machine regularly to remove debris and contaminants

- Lubricate moving parts and inspect for wear and tear

- Check and tighten bolts, screws, and other fasteners

- Monitor fluid levels and replenish as needed

- Follow manufacturer’s instructions for maintenance and cleaning procedures

6. Describe the importance of safety protocols in operating casing machines.

- Prevent accidents and injuries to oneself and others

- Protect the machine from damage and ensure its proper operation

- Maintain a clean and organized work environment

- Ensure compliance with safety regulations and industry standards

- Create a positive and productive work atmosphere

7. What types of information can be found in a casing machine’s operating manual?

A casing machine’s operating manual typically contains the following information:

- Machine specifications, including dimensions, weight, and power requirements

- Safety instructions and operating procedures

- Maintenance and cleaning guidelines

- Troubleshooting tips and error codes

- Warranty information

8. How do you stay updated on the latest advancements in casing machine technology?

- Attend industry conferences and exhibitions

- Read trade publications and technical journals

- Network with other Casing Machine Operators and professionals

- Participate in online forums and discussion groups

- Explore manufacturer websites and product catalogs

9. What strategies do you use to minimize waste and optimize production efficiency?

- Proper machine setup and calibration to reduce rejects

- Continuous monitoring of the production process and making adjustments as needed

- Regular maintenance and cleaning to prevent breakdowns

- Training and empowering team members to identify and resolve issues quickly

- Implementing lean manufacturing principles to eliminate waste and improve efficiency

10. How do you handle working in a fast-paced production environment?

- Prioritize tasks and manage time effectively

- Maintain a high level of focus and attention to detail

- Communicate clearly and effectively with team members

- Stay calm under pressure and make quick decisions

- Seek support when needed and offer assistance to others

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Casing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Casing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Casing Machine Operators are responsible for overseeing the operation of casing machines, which are used to produce a variety of products, including food and beverage cans, aerosol cans, and paint cans. They ensure that the machine is running smoothly and efficiently, and that the products meet quality standards.

1. Machine Operation and Maintenance

Operate and maintain casing machines, including setting up, adjusting, and troubleshooting

- Monitor machine performance and make necessary adjustments to ensure optimal production

- Inspect and clean machines regularly to maintain productivity and prevent breakdowns

2. Quality Control

Inspect products for defects and ensure they meet quality standards

- Conduct visual inspections and use measuring tools to verify product specifications

- Identify and remove defective products from the production line

3. Production Planning and Scheduling

Plan and schedule production runs to meet customer demands

- Coordinate with other departments to ensure timely delivery of materials and finished products

- Adjust production schedules to accommodate changes in demand or machine performance

4. Safety and Compliance

Follow safety procedures and maintain a clean and organized work environment

- Adhere to all applicable safety regulations and standards

- Report any safety hazards or concerns to supervisors

Interview Tips

Preparing for an interview for a Casing Machine Operator position requires thorough research and practice to make a lasting impression. Here are some essential tips to help you ace the interview:

1. Research the Company and Position

Before the interview, take the time to thoroughly review the company’s website, social media pages, and industry news to gain insights into their culture, values, and recent developments. Additionally, carefully read the job description and identify the key responsibilities and qualifications required for the role.

- Highlight your relevant skills and experience that align with the job requirements.

- Prepare examples and quantifiable results to demonstrate your abilities in machine operation, quality control, and production planning.

2. Practice Answering Common Interview Questions

Anticipate common interview questions and prepare thoughtful responses that showcase your skills and experience. Some common questions you may encounter include:

- Tell me about your experience operating casing machines.

- Describe your approach to maintaining and troubleshooting equipment.

- How do you ensure that products meet quality standards?

- How do you handle production schedule changes or unexpected challenges?

3. Be Confident and Enthusiastic

Throughout the interview, maintain a positive and confident demeanor. Show enthusiasm for the role and express your interest in joining the company. Remember to actively listen to the interviewer’s questions and ask thoughtful questions of your own to demonstrate your engagement and curiosity.

4. Dress Professionally and Arrive on Time

First impressions matter, so dress professionally and arrive on time for your interview. Your appearance and punctuality demonstrate respect for the interviewer and the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Casing Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!