Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Condenser Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

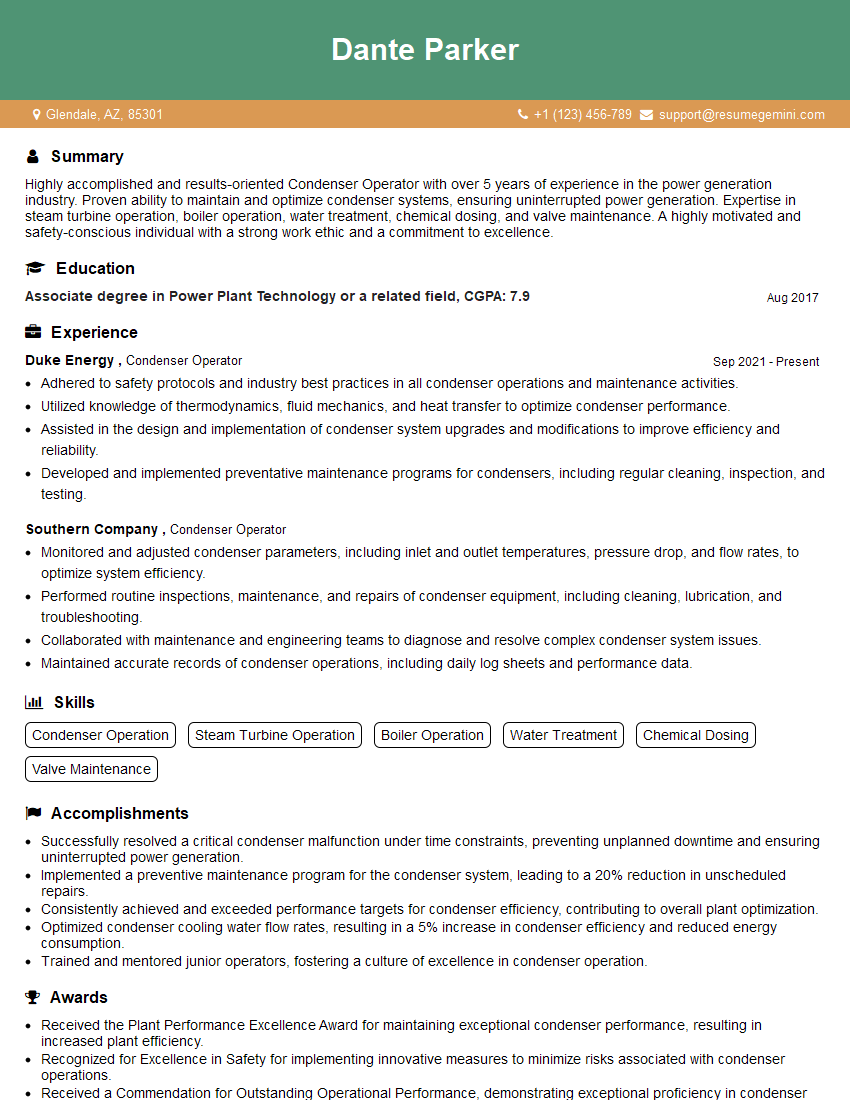

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Condenser Operator

1. Explain the importance of maintaining vacuum in a condenser?

Maintaining vacuum in a condenser is critical for its efficient operation. A vacuum helps in the removal of non-condensable gases, which can interfere with heat transfer and reduce the condenser’s efficiency. By removing these gases, the vacuum allows for optimal condensation of the refrigerant, maximizing heat exchange and cooling capacity.

2. How do you ensure the proper operation of condenser fan motors?

Regular Maintenance

- Inspect fan motors regularly for any signs of damage or wear.

- Clean and lubricate fan motors as per the manufacturer’s recommendations.

Electrical Checks

- Test fan motors for proper voltage and current draw.

- Ensure that all electrical connections are tight and secure.

Performance Monitoring

- Monitor fan motor amperage to ensure it is within the specified range.

- Observe fan rotation and listen for any unusual noises or vibrations.

3. What safety precautions should be followed when working on a condenser?

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and hearing protection.

- Ensure the condenser is de-energized before performing any maintenance or repairs.

- Use caution when handling refrigerant, as it can be hazardous if inhaled or ingested.

- Be aware of potential electrical hazards and take necessary precautions.

- Follow all manufacturer’s instructions and safety guidelines.

4. How do you troubleshoot a condenser that is not cooling properly?

- Check the condenser fan motor for proper operation.

- Inspect the condenser coils for any blockages or dirt accumulation.

- Verify that the refrigerant charge is at the correct level.

- Check for any leaks in the refrigerant lines or condenser.

- Ensure that the thermostat is calling for cooling and is properly calibrated.

5. What is the purpose of the condenser water treatment system?

- To prevent the formation of scale and corrosion in the condenser tubes.

- To maintain the efficiency of heat transfer.

- To extend the lifespan of the condenser.

6. How do you monitor the performance of a condenser water treatment system?

- Regularly test the pH, conductivity, and hardness of the condenser water.

- Inspect the condenser tubes for any signs of scale or corrosion.

- Monitor the pressure drop across the condenser.

- Observe the operation of the chemical feed system.

7. What is the difference between an air-cooled condenser and a water-cooled condenser?

Air-Cooled Condenser

- Uses ambient air to remove heat from the refrigerant.

- Requires a large surface area for heat transfer.

- Less efficient than water-cooled condensers.

Water-Cooled Condenser

- Uses water to remove heat from the refrigerant.

- More efficient than air-cooled condensers.

- Requires a source of cooling water.

8. What are the common types of condenser failures?

- Refrigerant leaks

- Electrical failures

- Mechanical failures

- Corrosion

- Scaling

9. How do you prioritize different condenser maintenance tasks?

- Safety-related tasks (e.g., electrical inspections) are given top priority.

- Tasks that affect the efficiency and performance of the condenser (e.g., coil cleaning) are scheduled regularly.

- Preventative maintenance tasks (e.g., water treatment system monitoring) are performed on a predetermined schedule.

- Reactive maintenance tasks (e.g., leak repair) are addressed as needed.

10. What are the key performance indicators (KPIs) for a condenser operator?

- Condenser efficiency

- Condenser water quality

- Condenser uptime

- Maintenance costs

- Refrigerant leaks

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Condenser Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Condenser Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Condenser Operators play a critical role in ensuring the efficient and safe operation of power plants and industrial facilities. Here are their primary responsibilities:

1. Plant Operations

Operate and maintain condensers, including performing routine checks, troubleshooting issues, and making necessary repairs.

- Monitor condenser performance, including pressure, temperature, and flow rates.

- Adjust condenser settings to optimize efficiency and prevent equipment damage.

2. Water Management

Manage the cooling water system, including controlling water flow rates, monitoring water quality, and performing water treatment.

- Ensure sufficient water supply to the condenser.

- Monitor and adjust water treatment chemicals to prevent corrosion and scaling.

3. Equipment Maintenance

Perform preventive and corrective maintenance on condenser and auxiliary equipment.

- Inspect and clean condenser tubes and water boxes.

- Replace worn or damaged components, such as gaskets and seals.

4. Safety and Environmental Compliance

Adhere to all safety regulations and environmental standards related to condenser operations.

- Follow proper lockout/tagout procedures before performing maintenance.

- Monitor and report any potential environmental hazards.

Interview Tips

Preparing thoroughly for your Condenser Operator interview will significantly increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Demonstrate your interest in the company and industry by researching their website, news articles, and industry publications.

- Understand the company’s mission, values, and recent developments.

- Gain insights into the industry trends and challenges.

2. Practice Your Responses

Prepare for common interview questions by practicing your responses. Use the STAR method (Situation, Task, Action, Result) to provide detailed and structured answers.

- Describe a time you successfully identified and resolved a condenser issue.

- Share your experience in implementing water treatment strategies.

3. Highlight Technical Expertise

Emphasize your technical knowledge and skills related to condenser operations. Provide specific examples of your experience with condenser types, maintenance procedures, and troubleshooting.

- Discuss your understanding of cooling water system design and principles.

- Describe your experience using specialized tools and equipment.

4. Showcase Safety and Compliance Awareness

Demonstrate your commitment to safety and environmental compliance by highlighting your knowledge of regulations and best practices.

- Emphasize your adherence to lockout/tagout procedures.

- Explain your experience in monitoring and reporting environmental hazards.

5. Prepare Questions for the Interviewer

Asking well-thought-out questions shows your engagement and interest in the role and company. Prepare questions related to the specific responsibilities, growth opportunities, and the organization’s culture.

- Inquire about the company’s approach to condenser maintenance and optimization.

- Ask about opportunities for professional development and training.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Condenser Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.