Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Core Winding Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Core Winding Operator so you can tailor your answers to impress potential employers.

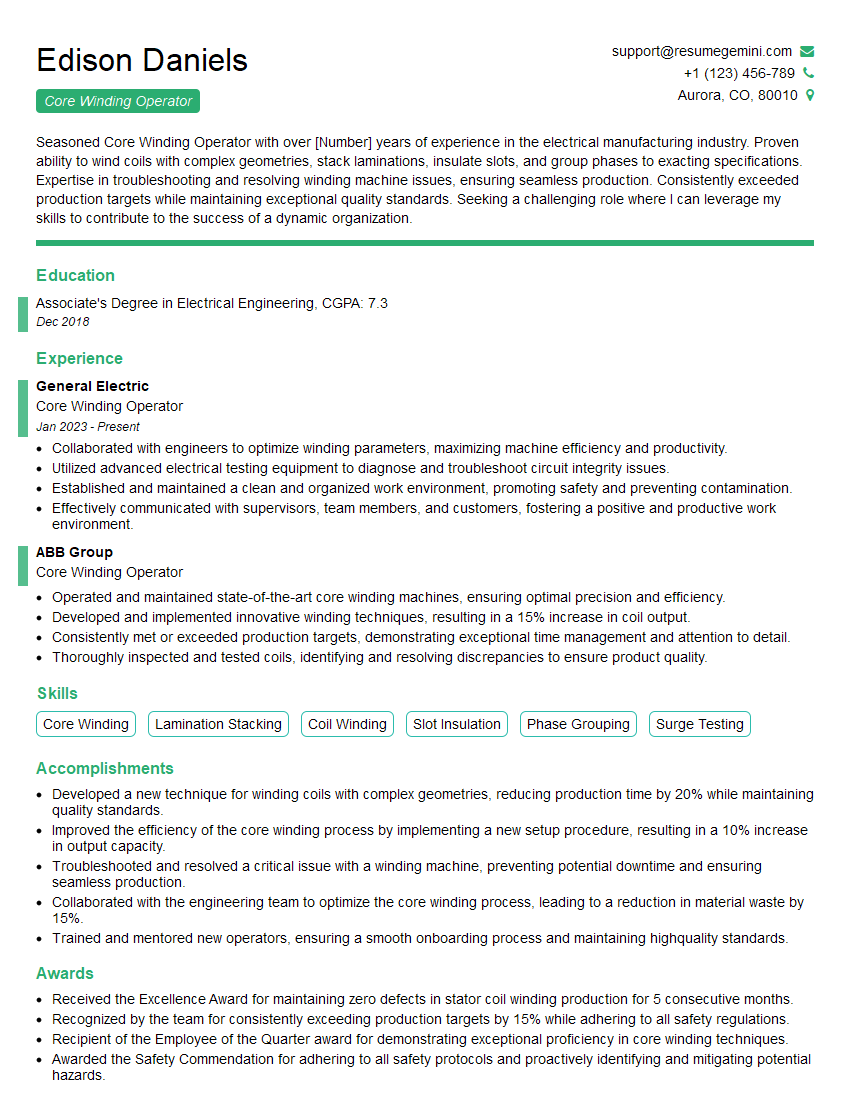

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Core Winding Operator

1. Explain the different types of core winding machines and their applications?

- Linear Winding Machines: These machines are used for winding coils with a linear shape and are commonly employed in the production of transformers, inductors, and motors.

- Toroidal Winding Machines: These machines are designed for winding coils with a toroidal shape and are often used in the manufacturing of transformers, inductors, and sensors.

- Radial Winding Machines: These machines are utilized for winding coils with a radial shape and are frequently used in the production of motors, generators, and alternators.

- Helical Winding Machines: These machines are employed for winding coils with a helical shape and are commonly used in the manufacturing of solenoids, actuators, and relays.

2. Discuss the key factors to consider when selecting the appropriate core winding machine for a specific application?

Factors to Consider:

- Type of coil being wound: The shape and size of the coil will determine the type of winding machine required.

- Material of the coil: Different materials have different winding requirements, and the machine must be compatible with the material being used.

- Production volume: The number of coils that need to be wound will determine the speed and efficiency of the winding machine.

- Quality requirements: The precision and accuracy required for the wound coils will influence the choice of winding machine.

- Cost and budget: The cost of the winding machine and its ongoing maintenance costs must be considered.

3. Describe the process of winding a toroidal core?

- Prepare the toroidal core by cleaning and inspecting it.

- Set up the winding machine with the appropriate tooling and tension settings.

- Load the wire onto the winding machine.

- Start the winding process, ensuring that the turns are evenly spaced and the tension is consistent.

- Monitor the winding process and make adjustments as needed.

- Once the winding is complete, secure the ends of the wire and cut off any excess.

- Inspect the finished coil for any defects or irregularities.

4. How do you ensure the quality of the wound coils?

- Visual inspection: Examine the coils for any visible defects, such as misalignment, loose windings, or damaged insulation.

- Electrical testing: Perform electrical tests, such as inductance, resistance, and voltage withstand tests, to ensure the coils meet the specified electrical requirements.

- Dimensional inspection: Measure the coils to ensure they meet the specified dimensions and tolerances.

- Temperature testing: Conduct temperature tests to ensure the coils can withstand the operating temperature range without overheating.

- Reliability testing: Perform reliability tests, such as vibration and shock tests, to ensure the coils can withstand the expected operating conditions.

5. How do you troubleshoot common problems encountered during core winding?

- Loose windings: Check the tension settings and ensure the wire is properly guided during winding.

- Misalignment: Adjust the tooling and ensure the core is properly positioned before winding.

- Damaged insulation: Inspect the wire for any damage and replace any damaged sections.

- Electrical shorts: Identify the source of the short circuit using electrical testing and repair or replace the affected components.

- Overheating: Check the temperature of the coil and ensure proper ventilation. Adjust the winding speed or tension settings as necessary.

6. What are the safety precautions that should be taken when operating core winding machines?

- Wear appropriate safety gear, such as safety glasses, gloves, and protective clothing.

- Keep the work area clean and organized to prevent tripping hazards.

- Ensure that the winding machine is properly grounded to prevent electrical shocks.

- Never operate the winding machine without proper training and authorization.

- Be aware of pinch points and moving parts of the machine to avoid injuries.

7. What is your experience with different types of core materials, such as ferrite, iron, and powdered iron?

- Ferrite: I have experience winding coils on ferrite cores, which are commonly used in high-frequency applications due to their low losses and high permeability.

- Iron: I have worked with iron cores, which are known for their high saturation flux density and are often used in power transformers and inductors.

- Powdered iron: I have experience winding coils on powdered iron cores, which offer a combination of high permeability and low losses, making them suitable for a wide range of applications.

8. How do you stay up-to-date with the latest advancements in core winding technology?

- Attend industry conferences and workshops.

- Read technical journals and articles related to core winding.

- Network with other core winding professionals.

- Stay informed about new products and technologies from winding machine manufacturers.

- Participate in online forums and discussion groups related to core winding.

9. Describe a challenging core winding project that you have worked on and how you overcame the challenges?

- Describe the project and the specific challenges you encountered.

- Explain how you analyzed the challenges and developed solutions.

- Highlight the steps you took to overcome the challenges and achieve a successful outcome.

- Discuss the lessons learned from the project and how they have improved your skills and knowledge.

10. What are your career goals and aspirations in the field of core winding?

- Express your passion for core winding and your desire to continue developing your skills.

- State your goals for career advancement, such as becoming a lead operator or supervisor.

- Discuss your aspirations to contribute to the field through innovation or research.

- Explain how your skills and experience align with the company’s goals and how you can contribute to their success.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Core Winding Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Core Winding Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Core Winding Operators play a crucial role in the production process, ensuring the precision and efficiency of electrical components.

1. Coil Winding

The primary responsibility involves winding coils with precise wire specifications, following established procedures and drawings.

- Calculate coil parameters, such as turns, pitch, and wire size, based on design specifications.

- Operate winding machines to wrap wire around coil formers, maintaining consistent tension and spacing.

- Inspect coils for defects, ensuring they meet quality standards.

2. Transformer Assembly

Core Winding Operators are responsible for assembling transformers, ensuring accurate placement and insulation of coils.

- Position coils on transformer cores, adhering to design specifications.

- Install insulation materials to prevent electrical shorts and ensure proper operation.

- Test transformer assemblies for continuity and insulation resistance.

3. Equipment Maintenance and Calibration

To ensure optimal performance, Core Winding Operators are responsible for maintaining and calibrating equipment.

- Clean and lubricate winding machines, coils, and tools.

- Calibrate equipment regularly to ensure accuracy and precision.

- Follow established maintenance schedules and report any issues promptly.

4. Quality Control

Core Winding Operators play a vital role in quality control, ensuring that components meet specifications and industry standards.

- Inspect coils and transformers for defects, such as shorts, opens, and insulation breakdowns.

- Record inspection results and report any discrepancies.

- Participate in quality improvement programs and suggest process enhancements.

Interview Tips

To ace the Core Winding Operator interview, preparation is crucial. Here are some tips and tricks to help you shine:

1. Research the Company and Position

Before the interview, thoroughly research the company’s history, products, and industry standing. Understanding the company’s values and mission will demonstrate your interest and alignment with their goals.

- Visit the company website and social media pages.

- Read recent news articles and industry publications.

- Prepare questions to ask the interviewer about the company’s future plans and growth opportunities.

2. Practice Answering Common Interview Questions

Anticipate common interview questions and practice your responses. This will boost your confidence and reduce anxiety during the actual interview.

- Tell me about yourself and why you’re interested in this position.

- Describe your experience in core winding and transformer assembly.

- What are your strengths and weaknesses as a Core Winding Operator?

- How do you handle working in a fast-paced environment?

3. Highlight Your Skills and Experience

Quantify your accomplishments and provide specific examples that showcase your skills and experience.

- Instead of saying “I wound coils,” say “I consistently exceeded production targets by 15% while maintaining high quality standards.”

- Highlight your proficiency in using winding machines, test equipment, and quality control tools.

4. Prepare Questions to Ask the Interviewer

Asking well-thought-out questions demonstrates your engagement and interest in the position. This is your opportunity to gather more information and assess if the job is a good fit for you.

- What is the company’s training and development program for Core Winding Operators?

- What are the performance expectations for this role?

- What is the company’s safety record and commitment to employee well-being?

5. Dress Professionally and Arrive on Time

First impressions matter. Dress professionally and arrive on time for your interview. This shows respect for the interviewer and the company, and it sets a positive tone for the conversation.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Core Winding Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.