Feeling lost in a sea of interview questions? Landed that dream interview for Covering Machine Tender but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Covering Machine Tender interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

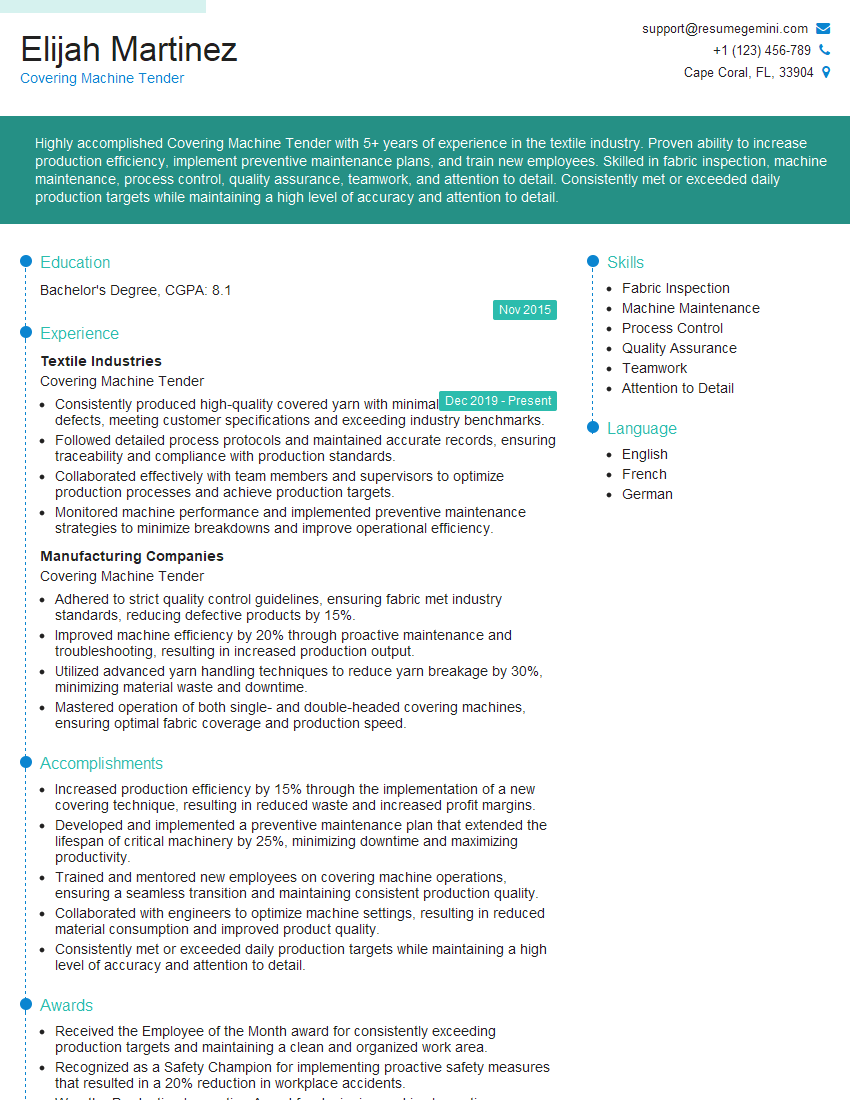

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Covering Machine Tender

1. What are the key responsibilities of a Covering Machine Tender?

- Operate covering machines to apply a protective layer of material to various products, such as wires, cables, and fabrics.

- Monitor machine operation, adjust settings, and perform maintenance as needed.

- Inspect covered products for defects and ensure quality standards are met.

2. Describe the different types of covering machines and their applications.

Braiding Machines

- Produce braided coverings for cables and hoses, providing flexibility and protection.

- Used in industries such as automotive, aerospace, and telecommunications.

Extruding Machines

- Melt and extrude materials such as rubber or plastic to form a protective layer on wires and cables.

- Used in various applications, including electrical insulation and automotive components.

Taping Machines

- Wrap tapes around wires and cables to provide insulation, protection, and strain relief.

- Used in electronics, electrical, and telecommunications industries.

3. How do you ensure the quality of the covered products?

- Regularly calibrate and inspect covering machines to maintain accuracy.

- Monitor the tension, thickness, and uniformity of the covering material.

- Conduct visual and physical inspections of covered products to identify defects.

4. What are the safety precautions that must be taken when operating covering machines?

- Wear appropriate personal protective equipment, such as gloves, safety glasses, and ear plugs.

- Follow lockout/tagout procedures when performing maintenance or repairs.

- Be aware of moving parts and potential hazards, such as hot surfaces or sharp edges.

5. How do you troubleshoot common problems with covering machines?

- Identify the symptom and potential causes of the problem.

- Check machine settings, tension, and material flow.

- Perform necessary adjustments or repairs to resolve the issue.

6. What is the importance of maintaining proper tension when covering products?

- Correct tension ensures the covering material is applied evenly and securely.

- Prevents the covering from being too loose or too tight, which can affect the product’s performance or lifespan.

7. How do you calculate the coverage rate for a given material and product?

Coverage rate = (Weight of covering material used) / (Weight of covered product)

- Determine the weight of the covering material and the covered product.

- Divide the weight of the covering material by the weight of the covered product to obtain the coverage rate.

8. What are the different methods used to join covering materials?

- Overlapping: Two ends of the material are overlapped and secured with tape or adhesive.

- Butt-joining: Two ends of the material are placed next to each other and joined using heat, glue, or stitching.

- Splitting and weaving: The material is split into two strands, which are then woven together to create a continuous covering.

9. How do you minimize waste when covering products?

- Optimize the cutting process to reduce material scraps.

- Properly adjust machine settings to avoid excess covering.

- Utilize leftover materials for smaller products or repairs.

10. What is your experience and knowledge of different types of covering materials?

- List the types of covering materials you have worked with, such as rubber, plastic, fabric, or metal.

- Describe their properties, applications, and any specific techniques required for handling them.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Covering Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Covering Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Covering Machine Tenders are responsible for operating, monitoring, and maintaining covering machines used in the manufacturing process. Their key responsibilities include:

1. Machine Operation

• Setting up and operating covering machines.

• Adjusting machine settings to produce the desired product specifications.

• Monitoring machine operation to ensure smooth and efficient production.

2. Product Handling

• Loading and unloading materials onto and from the machine.

• Inspecting products for quality and accuracy.

• Ensuring product specifications are met.

3. Machine Maintenance

• Performing routine maintenance and cleaning of the machine.

• Identifying and reporting any malfunctions or defects.

• Participating in preventive maintenance programs.

4. Safety and Compliance

• Complying with all safety regulations and procedures.

• Ensuring a safe and clean work environment.

• Following proper lockout/tagout procedures.

Interview Tips

To prepare for an interview for a Covering Machine Tender position, consider the following tips:

1. Research the Company

Learn about the company’s industry, products, and culture. This will help you understand the company’s needs and how your skills can contribute to their success.

2. Practice Common Interview Questions

Prepare for common interview questions such as “Tell me about yourself,” “Why are you interested in this position,” and “What are your strengths and weaknesses.”

3. Highlight Relevant Skills and Experience

Emphasize your skills and experience in operating and maintaining covering machines. Quantify your accomplishments whenever possible.

4. Demonstrate Your Knowledge of the Industry

Show the interviewer that you are knowledgeable about the covering machine industry. Discuss any trends or best practices that you are familiar with.

5. Be Enthusiastic and Professional

Convey your enthusiasm for the position and the manufacturing industry. Maintain a professional demeanor throughout the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Covering Machine Tender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!