Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Cylinder Handler position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

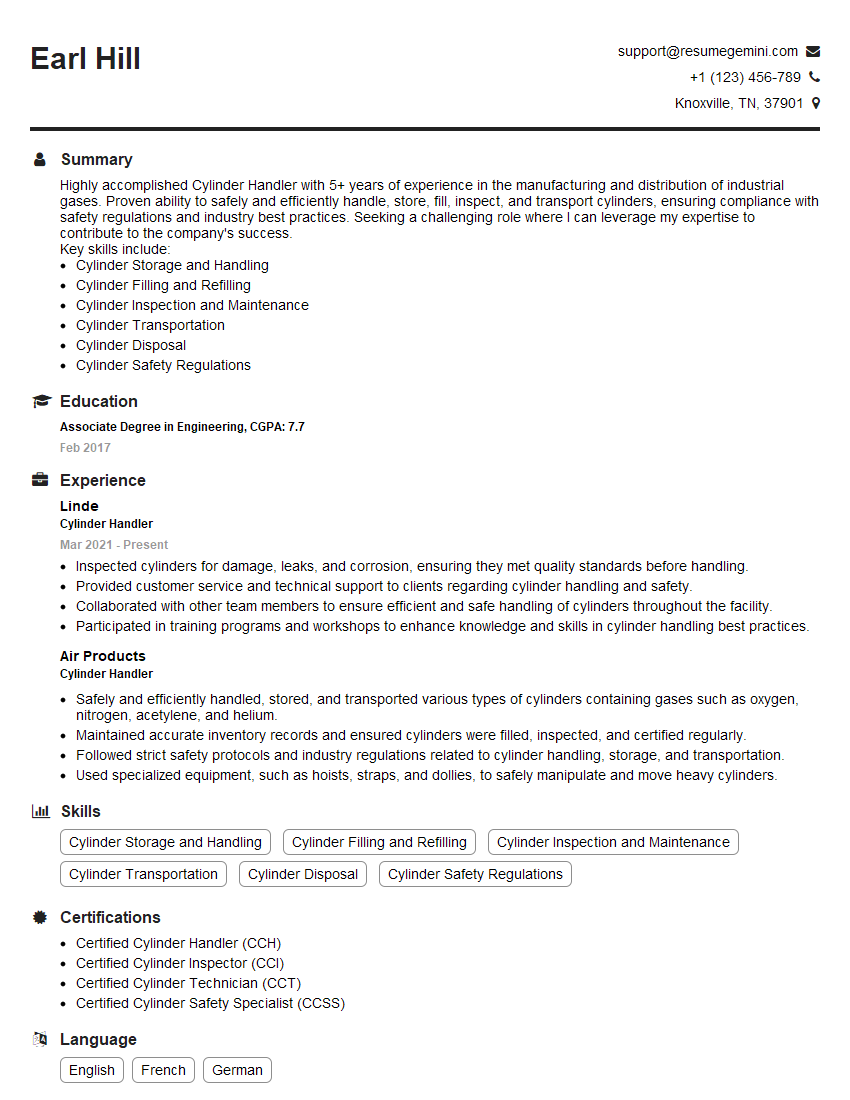

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cylinder Handler

1. Describe the steps involved in loading and unloading gas cylinders.

- Inspect the cylinders to ensure they are in good condition and free of any defects.

- Put on appropriate personal protective equipment (PPE), including gloves and safety glasses.

- Use a forklift or other material handling equipment to lift the cylinders onto the loading dock or truck.

- Secure the cylinders in place using chains or straps.

- Unload the cylinders in the reverse order of loading.

2. What are the safety precautions that must be taken when handling gas cylinders?

subheading of the answer

- Never lift a cylinder by the valve or cap.

- Always use a hand truck or other material handling equipment to move cylinders.

- Keep cylinders upright at all times.

- Do not roll cylinders on their sides.

- Secure cylinders in place when transporting them.

subheading of the answer

- Never smoke or use open flames near cylinders.

- Store cylinders in a cool, dry place away from direct sunlight.

- Inspect cylinders regularly for leaks or damage.

- Train all employees who handle cylinders on the proper safety procedures.

3. What types of gas cylinders have you handled in the past?

- Oxygen cylinders

- Acetylene cylinders

- Nitrogen cylinders

- Argon cylinders

- Helium cylinders

4. What is the difference between a compressed gas cylinder and a liquefied gas cylinder?

- Compressed gas cylinders contain gas that is compressed under high pressure.

- Liquefied gas cylinders contain gas that is liquefied under high pressure.

- Compressed gas cylinders are typically used for gases that are not easily liquefied, such as oxygen and nitrogen.

- Liquefied gas cylinders are typically used for gases that are easily liquefied, such as propane and butane.

5. What are the different types of valves used on gas cylinders?

- Cylinder valves are used to control the flow of gas from the cylinder.

- There are many different types of cylinder valves, each with its own unique design and purpose.

- The most common type of cylinder valve is the CGA valve.

- CGA valves are designed to be used with specific types of gas cylinders.

6. How do you inspect a gas cylinder for leaks?

- Inspect the cylinder for any visible damage, such as dents, cracks, or corrosion.

- Use a leak detector to check for leaks around the valve, fittings, and body of the cylinder.

- If a leak is detected, immediately close the cylinder valve and tag the cylinder as defective.

7. What should you do if you discover a leak in a gas cylinder?

- Immediately close the cylinder valve.

- Tag the cylinder as defective.

- Move the cylinder to a safe location away from people andignition sources.

- Contact your supervisor or the gas supplier for further instructions.

8. What are the different types of material handling equipment used to move gas cylinders?

- Forklifts

- Hand trucks

- Cylinder carts

- Overhead cranes

- Chain hoists

- Conveyors

9. How do you load and unload gas cylinders from a truck?

- Use a forklift or other material handling equipment to lift the cylinders onto the loading dock or truck.

- Secure the cylinders in place using chains or straps.

- Unload the cylinders in the reverse order of loading.

10. What are the different types of training required for cylinder handlers?

- General cylinder handling safety training

- Training on the specific types of cylinders that will be handled

- Training on the material handling equipment that will be used to move cylinders

- Training on the emergency procedures to be followed in the event of a leak or other incident

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cylinder Handler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cylinder Handler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cylinder Handlers are responsible for ensuring proper handling and transportation of cylinders at the workplace. Their primary duties include ensuring safety protocols, maintaining equipment, and handling inventory.1. Safety Compliance

- Ensures compliance with all relevant safety regulations, including proper use of personal protective equipment (PPE) and handling of hazardous materials.

- Adheres to established safety procedures for cylinder handling, storage, and transportation.

- Identifies and assesses potential hazards or risks, implementing preventive measures to minimize accidents.

2. Equipment Maintenance

- Inspects and verifies proper operation of equipment related to cylinder handling, such as forklifts, hoists, and cylinder racks.

- Conducts routine maintenance tasks, including lubrication, cleaning, and minor repairs, to maintain equipment reliability.

- Reports any equipment malfunctions or irregularities promptly to ensure timely repairs.

3. Inventory Management

- Maintains an accurate inventory of cylinders, tracking their location, status, and usage.

- Facilitates cylinder transfers between designated areas, ensuring timely delivery and availability of gases.

- Monitors cylinder stock levels and places new orders as needed to meet operational requirements.

4. Loading and Unloading

- Safely loads and unloads cylinders onto transport vehicles, ensuring secure fastening and compliance with load limits.

- Inspects cylinders for damage or leaks before loading or unloading and takes appropriate actions.

- Follows established procedures for cylinder handling, including proper lifting techniques and the use of appropriate equipment.

Interview Preparation Tips

To prepare for a Cylinder Handler interview, candidates should focus on demonstrating their knowledge of safety protocols, equipment handling, and inventory management. Here are some tips to help you ace the interview:1. Research the Company and Industry

Learn about the company’s safety regulations, industry standards, and specific requirements for Cylinder Handlers. This will demonstrate your interest in the position and your commitment to safety.2. Highlight Safety and Compliance

Emphasize your understanding of safety regulations and your commitment to following proper procedures. Showcase your experience in identifying and mitigating hazards to ensure a safe work environment.3. Demonstrate Equipment Proficiency

Describe your experience operating and maintaining equipment used for cylinder handling, such as forklifts and hoists. Highlight your ability to conduct routine maintenance and troubleshoot common issues.4. Explain Inventory Management Skills

Explain your experience in maintaining inventory records, tracking cylinder usage, and coordinating cylinder transfers. This will demonstrate your ability to manage inventory effectively.5. Practice Interview Questions

Prepare for common interview questions and practice your responses. Consider questions related to safety procedures, equipment handling, and inventory management.6. Ask Informed Questions

Ask insightful questions during the interview to show your interest and engagement. This could include questions about the company’s safety culture, training programs, or growth opportunities for Cylinder Handlers.Next Step:

Now that you’re armed with the knowledge of Cylinder Handler interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Cylinder Handler positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini