Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Do All Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

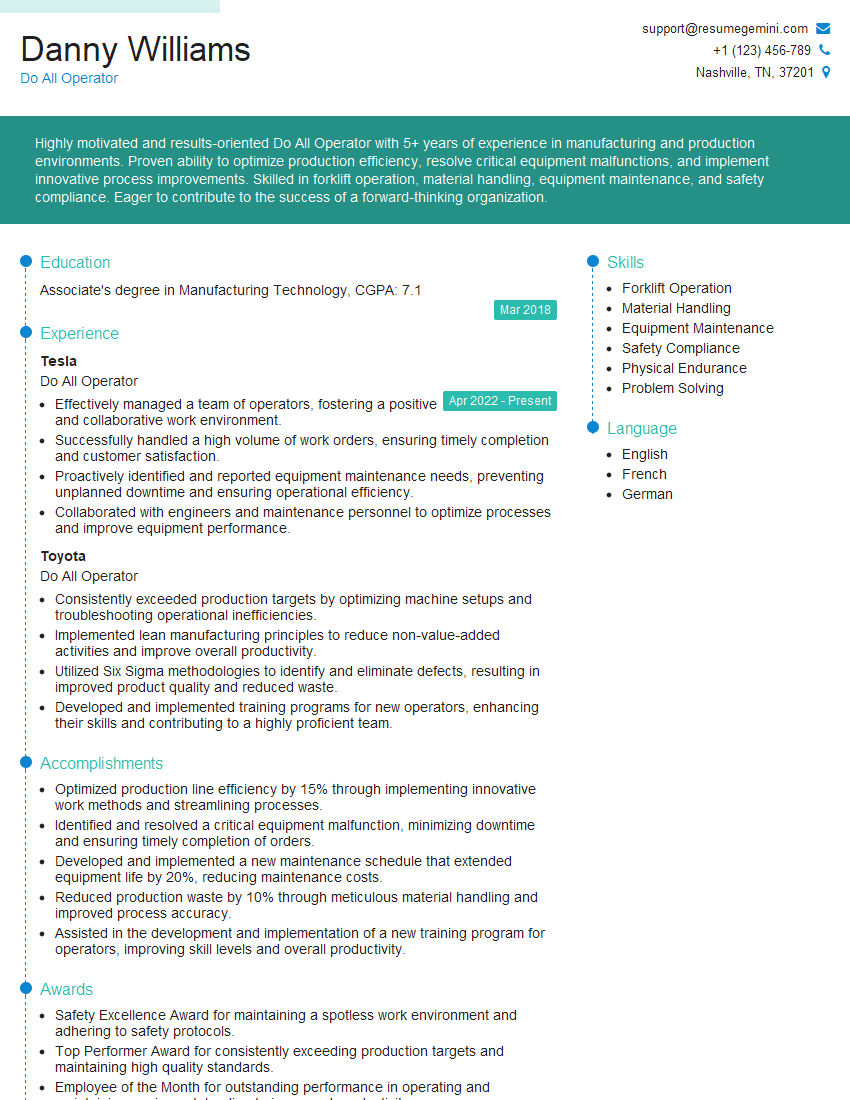

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Do All Operator

1. What safety precautions should be followed when operating a do-all machine?

- Always wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and earplugs.

- Inspect the machine before each use and ensure all guards and safety devices are in place and functioning properly.

- Keep work area clean and free of debris or tripping hazards.

- Never operate the machine under the influence of drugs or alcohol.

- Be aware of your surroundings and maintain a safe distance from other workers or objects.

2. How do you set up and calibrate a do-all machine for a specific task?

Material Loading

- Choose the appropriate material for the task.

- Load the material into the machine’s hopper or tray.

Machine Settings

- Select the desired settings for the machine, such as speed, pressure, and temperature.

- Adjust the machine’s settings according to the manufacturer’s instructions or as directed by a supervisor.

Calibration

- Use a calibration tool or gauge to ensure the machine is operating within acceptable tolerances.

- Make any necessary adjustments to the machine’s settings to achieve the desired results.

3. What are the different types of tools and attachments that can be used with a do-all machine?

- Cutting tools (e.g., saws, drills, routers)

- Shaping tools (e.g., sanders, grinders, buffers)

- Forming tools (e.g., presses, brakes, rolls)

- Welding and soldering attachments

- Pneumatic and hydraulic tools

4. How do you troubleshoot common problems that may occur when operating a do-all machine?

- Identify the problem and its potential cause.

- Refer to the machine’s operator’s manual or consult a qualified technician for guidance.

- Check for any loose connections, damaged parts, or worn-out components.

- Perform basic troubleshooting steps, such as cleaning, tightening, or replacing parts.

- If the problem persists, contact a qualified technician for further assistance.

5. How do you maintain and clean a do-all machine to ensure its longevity?

- Regularly clean the machine’s exterior and interior components.

- Lubricate moving parts as per the manufacturer’s recommendations.

- Inspect and replace worn or damaged parts promptly.

- Store the machine in a clean and dry environment when not in use.

- Follow the manufacturer’s maintenance schedule and guidelines.

6. What types of materials can be processed using a do-all machine?

- Wood

- Metal

- Plastic

- Glass

- Composite materials

7. Explain the process of using a do-all machine to cut metal.

- Select the appropriate cutting tool for the type of metal being cut.

- Secure the metal piece firmly in place on the machine’s table.

- Set the machine’s speed and feed rate according to the material and cutting tool being used.

- Start the machine and guide the cutting tool along the desired cutting path.

- Once the cut is complete, stop the machine and remove the cut piece.

8. How do you ensure the accuracy of cuts made using a do-all machine?

- Use sharp and properly maintained cutting tools.

- Secure the material firmly in place on the machine’s table.

- Set the machine’s speed and feed rate according to the material and cutting tool being used.

- Use a fence or guide to ensure straight cuts.

- Check the accuracy of cuts regularly using a measuring tool.

9. What are the safety precautions that should be taken when using a do-all machine to weld?

- Wear appropriate personal protective equipment, including welding helmet, gloves, and protective clothing.

- Ensure the work area is well-ventilated and free of flammable materials.

- Ground the welding machine properly.

- Inspect the welding equipment regularly and ensure it is in good working condition.

- Follow the manufacturer’s instructions for safe welding practices.

10. How do you troubleshoot a do-all machine that is not welding properly?

- Check the power supply and ensure the machine is receiving adequate voltage.

- Inspect the welding torch and cables for any damage or loose connections.

- Check the gas supply and ensure it is flowing properly.

- Adjust the welding settings according to the manufacturer’s recommendations.

- If the problem persists, contact a qualified technician for further assistance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Do All Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Do All Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Do All Operators play a crucial role in manufacturing and production environments. They are responsible for a wide range of tasks, ensuring the smooth operation of machines, production lines, and other essential equipment.

1. Machine Operation

Operate various machines, such as CNC machines, lathes, grinders, and presses, according to specified instructions and production schedules.

- Monitor machine performance and make adjustments to optimize production.

- Perform routine maintenance and troubleshooting to keep machines in good working order.

2. Production Monitoring

Monitor production processes and ensure adherence to quality standards.

- Conduct inspections and testing on finished products.

- Identify and resolve production issues promptly.

3. Material Handling

Load and unload materials, such as raw materials, parts, and finished goods.

- Use forklifts, cranes, and other equipment to move materials safely and efficiently.

- Maintain an organized and clean work area.

4. Equipment Maintenance

Perform basic maintenance and repairs on machinery and equipment.

- Lubricate, clean, and adjust equipment to prevent breakdowns.

- Identify potential problems and notify supervisors.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some helpful tips to assist you in acing your Do All Operator interview:

1. Research the Company and Role

Take the time to research the company, its industry, and the specific Do All Operator role you’re applying for. This will demonstrate your interest and enthusiasm for the position.

- Visit the company’s website and social media pages.

- Read industry publications and news articles.

2. Practice Common Interview Questions

Prepare for common interview questions by practicing your answers in advance. Consider using the STAR method to structure your responses:

- Situation: Describe the situation you were in.

- Task: Explain the task you were responsible for.

- Action: Outline the actions you took.

- Result: Describe the positive outcome or impact of your actions.

3. Highlight Relevant Skills and Experience

Emphasize your relevant skills and experience that align with the job requirements. Use specific examples to demonstrate your abilities.

- Quantify your accomplishments whenever possible.

- Be prepared to discuss your knowledge of different machinery and production processes.

4. Be Enthusiastic and Professional

Maintain a positive and enthusiastic attitude throughout the interview. Dress professionally and arrive on time.

- Be courteous and respectful to the interviewer.

- Ask thoughtful questions to show your engagement and interest in the role.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Do All Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Do All Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.