Feeling lost in a sea of interview questions? Landed that dream interview for Drier and Grinder Tender but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Drier and Grinder Tender interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

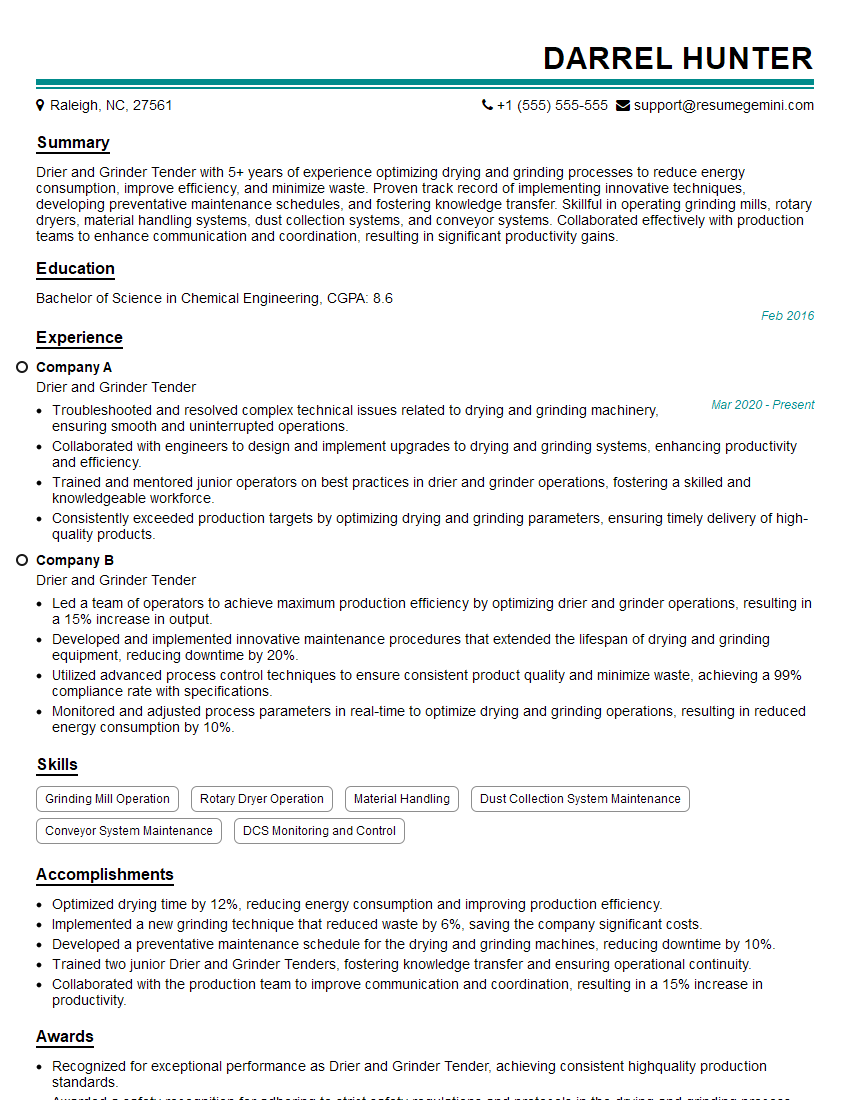

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Drier and Grinder Tender

1. What are the key responsibilities of a Drier and Grinder Tender?

As a Drier and Grinder Tender, I would be responsible for operating and maintaining drying and grinding equipment, ensuring the efficient and safe production of dried and ground products.

- Operate and monitor driers and grinders to dry and grind materials according to specifications.

- Adjust settings and make necessary repairs to ensure optimal performance of the equipment.

- Monitor product quality and make adjustments to ensure it meets customer requirements.

- Maintain a clean and organized work area, adhering to safety regulations and procedures.

- Keep accurate records of production and maintenance activities.

2. How do you ensure the proper drying of materials?

Monitoring Temperature and Airflow

- Continuously monitor the temperature of the drying process to prevent over-drying or under-drying.

- Ensure proper airflow throughout the drying chamber to facilitate efficient moisture removal.

Adjusting Drying Time

- Adjust the drying time based on the type of material and desired moisture content.

- Use moisture meters or other testing methods to determine when the material has reached the desired dryness level.

Maintaining Equipment

- Regularly inspect and clean the drying equipment to prevent malfunctions or contamination.

- Perform preventive maintenance tasks to ensure the dryer is operating at peak efficiency.

3. What are the common types of grinders used in the industry?

- Hammer Mills: Use hammers to crush materials into smaller particles.

- Knife Mills: Employ rotating blades to cut and chop materials.

- Pin Mills: Utilize pins to grind materials into a fine powder.

- Disc Mills: Comprise two rotating discs that grind materials between them.

- Colloid Mills: Consist of a rotating rotor and stator to produce very fine and uniform particles.

4. How do you select the appropriate grinder for a specific material?

The selection of a suitable grinder depends on several factors:

- Material Properties: Hardness, particle size, and moisture content of the material.

- Desired Particle Size: The required fineness or coarseness of the ground product.

- Production Capacity: The desired output rate of the grinding process.

- Operational Considerations: Noise levels, energy consumption, and maintenance requirements.

5. What are the typical safety precautions to observe when operating a drier and grinder?

- Wear appropriate protective gear: Safety glasses, gloves, and earplugs.

- Follow lockout/tagout procedures: Isolate equipment before performing maintenance or repairs.

- Keep work area clean: Remove dust, debris, and materials that could cause slips or falls.

- Avoid contact with moving parts: Ensure guards and covers are in place and operational.

- Stay alert and focused: Pay attention to the equipment and surroundings to identify potential hazards.

6. How do you handle production deviations or equipment malfunctions?

- Identify the problem: Observe the equipment, product, and process parameters to determine the cause of the deviation.

- Take immediate action: Adjust settings, make repairs, or contact maintenance personnel as necessary.

- Communicate with supervisors: Report the issue and any corrective actions taken.

- Document the event: Record the details of the deviation, corrective actions, and any follow-up measures.

- Implement preventive measures: Analyze the root cause of the deviation and suggest improvements to prevent future occurrences.

7. How do you maintain the quality of dried and ground products?

- Monitor product quality: Regularly inspect the products for consistency, particle size, and moisture content.

- Calibrate equipment: Ensure that drying and grinding equipment is calibrated and operating within specified parameters.

- Follow standard operating procedures: Adhere to established procedures for drying and grinding to achieve consistent results.

- Conduct regular maintenance: Inspect and clean equipment to prevent contamination or performance issues.

- Implement quality control measures: Establish quality control checkpoints and testing methods to verify product quality.

8. How do you stay up-to-date with industry best practices and advancements in drying and grinding technologies?

- Attend industry events and conferences: Participate in workshops and seminars to learn about new technologies and innovations.

- Read industry publications and journals: Stay informed about the latest research and developments in the field.

- Network with industry professionals: Connect with peers and experts to exchange knowledge and ideas.

- Seek opportunities for professional development: Enroll in training programs or certification courses to enhance skills and knowledge.

9. How do you prioritize your tasks and manage your time effectively?

- Establish priorities: Identify the most important and urgent tasks and allocate time accordingly.

- Create a work schedule: Plan and organize work to ensure efficient use of time.

- Minimize interruptions: Find ways to minimize distractions and focus on completing tasks.

- Delegate tasks: If necessary, delegate tasks to others to free up time for more critical responsibilities.

- Seek support: Ask for help or guidance from supervisors or colleagues when needed.

10. How do you handle pressure and stress in a fast-paced work environment?

- Stay calm and collected: Maintain composure and avoid panic in stressful situations.

- Prioritize effectively: Focus on completing the most critical tasks first.

- Communicate effectively: Keep supervisors and colleagues informed of progress and any challenges encountered.

- Take breaks: Step away from the work area when feeling overwhelmed to clear the mind and regain focus.

- Seek support: Talk to supervisors or colleagues for support and advice when needed.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Drier and Grinder Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Drier and Grinder Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Drier and Grinder Tender operates and maintains drying and grinding equipment in various industries. Their core duties involve:

1. Equipment Operation

Inspect and prepare drying and grinding machines for operation.

- Monitor machines during operation to ensure efficient functioning.

- Adjust machine settings to optimize drying and grinding processes.

2. Maintenance and Inspection

Perform routine maintenance on equipment to prevent breakdowns and ensure safety.

- Lubricate moving parts, check bearings, and tighten bolts.

- Inspect equipment for damage or wear and initiate repairs or replacements as needed.

3. Material Handling

Load and unload materials, such as feedstock, into and out of equipment.

- Monitor material flow and adjust feed rates to maintain optimal processing conditions.

- Inspect materials for quality and contamination issues.

4. Process Monitoring and Control

Monitor drying and grinding processes to ensure proper operating conditions.

- Measure temperature, humidity, and other process parameters.

- Adjust controls based on process requirements and data analysis.

Interview Tips

To ace an interview for a Drier and Grinder Tender position, it’s crucial to prepare thoroughly. Here are some tips:

1. Research the Company and Role

Familiarize yourself with the company’s website, industry, and recent news. Research the specific job description to understand the requirements and expectations.

2. Prepare to Discuss Your Experience

Highlight your experience and skills that are relevant to the role. Quantify your accomplishments and provide specific examples to demonstrate your abilities.

Example:

- Instead of saying “I operated drying machines,” say “I operated and maintained 6 industrial drying machines, reducing downtime by 20%.”

- Instead of saying “I monitored grinding processes,” say “I monitored and controlled 4 grinding lines, optimizing production output by 15% while maintaining high quality standards.”

3. Be Ready for Technical Questions

Expect questions about drying and grinding processes, equipment maintenance, and safety protocols. Review technical terms and concepts related to the industry.

4. Highlight Your Problem-Solving Skills

Convey your ability to identify and resolve issues effectively. Describe instances where you encountered challenges and implemented solutions.

Example:

5. Emphasize Safety and Quality Control

Stress your commitment to safety protocols and quality standards. Provide examples of your attention to detail and ability to ensure the safe and efficient operation of drying and grinding equipment.

6. Practice Your Answers

Prepare for common interview questions. Practice answering them in a clear and concise manner, highlighting your skills and experience.

7. Dress Professionally and Be Punctual

Demonstrate your professionalism by dressing appropriately and arriving for the interview on time. Punctuality shows respect for the interviewer’s schedule.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Drier and Grinder Tender role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.