Are you gearing up for an interview for a Fiberglass Model Maker position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Fiberglass Model Maker and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

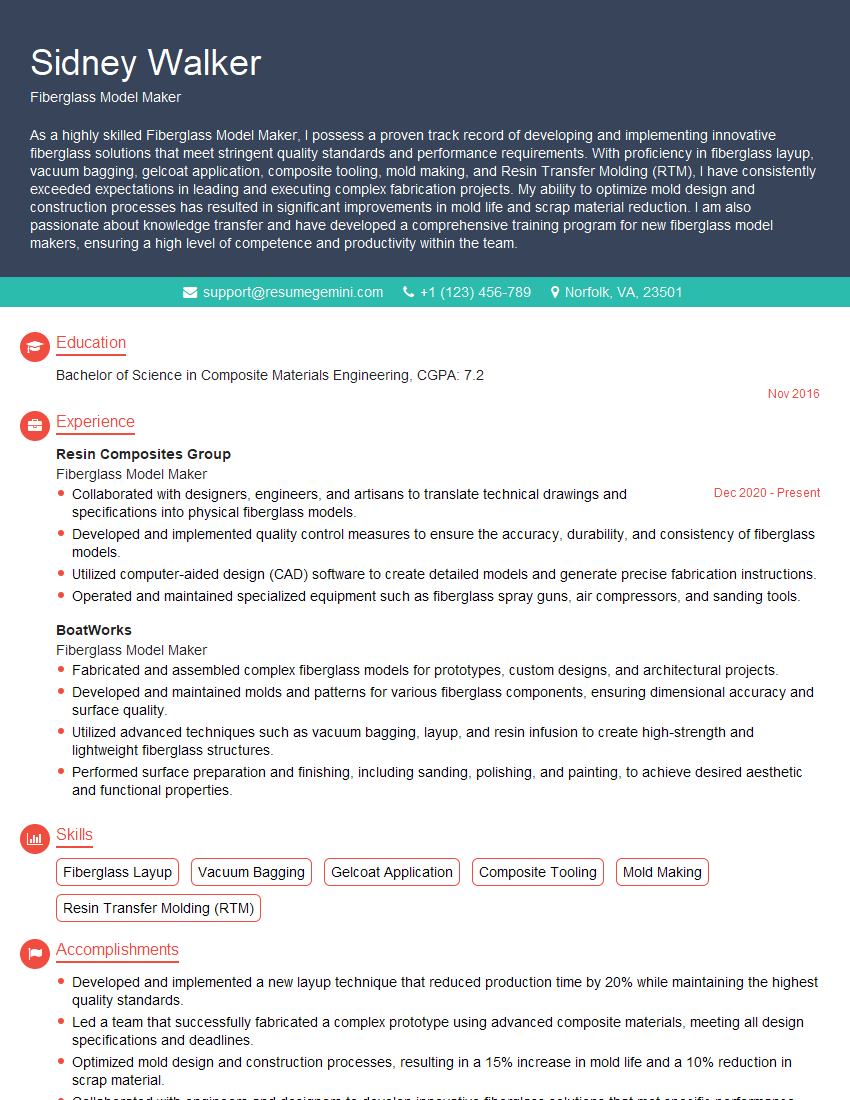

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fiberglass Model Maker

1. Explain the process of creating a fiberglass mold from a master model?

The process of creating a fiberglass mold from a master model involves the following steps:

- Prepare the master model by sealing any imperfections and applying a release agent.

- Build up the mold by applying layers of fiberglass mat or cloth over the master model, alternating with layers of resin.

- Allow the mold to fully cure and harden.

- Remove the mold from the master model.

- Inspect the mold for any imperfections and repair as necessary.

2. Describe the different types of fiberglass materials and their applications?

Gelcoats

- Protective outer layer applied to fiberglass laminates

- Provides a smooth, glossy finish

- Resistant to UV radiation and chemicals

Fiberglass Mat

- Randomly oriented glass fibers held together by a binder

- Used for structural applications and as a reinforcing layer

- Low cost and easy to work with

Fiberglass Cloth

- Woven glass fibers that provide high strength and rigidity

- Used for high-performance applications

- More expensive than fiberglass mat

Fiberglass Roving

- Continuous strands of glass fibers that provide maximum strength

- Used for reinforcing complex shapes and critical structural components

- Requires specialized equipment to apply

3. Explain the importance of resin selection in fiberglass molding?

- Strength and durability: Different resins offer varying levels of strength and impact resistance.

- Chemical resistance: Resins can vary in their resistance to chemicals, solvents, and UV radiation.

- Viscosity and working time: Resins with different viscosities affect the ease of application and the time available for working with the material.

- Curing time: The curing time of the resin determines how long it takes for the mold to fully harden.

- Cost: Resins vary in price, so it is important to consider the cost when selecting a resin for a specific application.

4. Describe the process of laminating fiberglass and the factors that affect the strength of the laminate?

Process of Laminating Fiberglass

- Applying alternating layers of fiberglass mat or cloth and resin.

- Compressing the layers together to remove air bubbles.

- Curing the laminate at the appropriate temperature and humidity.

Factors Affecting Laminate Strength

- Fiber orientation: The direction of the glass fibers affects the strength of the laminate.

- Resin content: The amount of resin used in the laminate affects its strength and stiffness.

- Curing conditions: The temperature and humidity during curing can affect the strength of the laminate.

- Thickness: The thicker the laminate, the stronger it will be.

5. Explain the techniques used to reinforce fiberglass molds and laminates?

- Adding ribs and flanges: These structural elements increase the strength and rigidity of the mold or laminate.

- Using thicker laminates: Increasing the thickness of the laminate increases its strength and durability.

- Adding core materials: Foam or honeycomb materials can be added between layers of fiberglass to provide additional support and reduce weight.

- Using fiberglass roving: Continuous strands of glass fibers provide maximum strength and reinforcement.

6. Describe the process of finishing a fiberglass mold or laminate?

- Trimming and sanding: Excess fiberglass is trimmed and the surface is sanded to achieve the desired shape and smoothness.

- Filling and fairing: Imperfections and gaps are filled with epoxy or polyester filler, then sanded smooth.

- Polishing: The surface is polished to achieve a glossy or matte finish.

- Applying a protective coating: A clear coat or wax can be applied to protect the surface from UV radiation and weathering.

7. Explain the safety precautions that must be taken when working with fiberglass?

- Wear protective clothing: Respirator, gloves, long sleeves, and pants to prevent skin and eye irritation from fiberglass dust and resin fumes.

- Use proper ventilation: Work in a well-ventilated area or use a respirator to avoid inhaling fiberglass dust and resin fumes.

- Handle chemicals safely: Resin and other chemicals should be handled according to the manufacturer’s instructions.

- Avoid contact with skin and eyes: Wear gloves and eye protection to prevent irritation.

- Follow proper disposal procedures: Dispose of fiberglass waste and used materials properly to prevent environmental contamination.

8. Describe the use of CAD/CAM in the fiberglass molding process?

- Creating 3D models: CAD software is used to create detailed 3D models of the desired part or mold.

- Generating toolpaths: CAM software generates toolpaths for CNC machines that cut and shape the fiberglass material.

- Optimizing material usage: CAD/CAM software can help optimize material usage by nesting parts and minimizing waste.

- Improving accuracy and efficiency: CAD/CAM technology allows for precise and efficient production of fiberglass parts and molds.

9. Explain the different methods of joining fiberglass parts?

- Mechanical fasteners: Bolts, screws, and rivets can be used to join fiberglass parts, but they can create stress concentrations.

- Adhesives: Epoxy and other adhesives can provide strong bonds between fiberglass parts.

- Lamination: Overlapping layers of fiberglass can be laminated together to create a strong joint.

- Stitching: Fiberglass parts can be stitched together using specialized needles and thread.

10. Describe the applications of fiberglass in various industries?

- Automotive: Body panels, bumpers, and interior components

- Marine: Boats, kayaks, and surfboards

- Aerospace: Aircraft parts, fairings, and cowlings

- Construction: Roofing, siding, and architectural panels

- Wind energy: Turbine blades and nacelles

- Medical: Prosthetics, medical devices, and equipment

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fiberglass Model Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fiberglass Model Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Fiberglass Model Makers play a crucial role in creating accurate and detailed fiberglass models for various industries. Their key job responsibilities include:

1. Model Design and Development

Analyze design specifications, sketches, and drawings to create prototypes.

- Develop and fabricate fiberglass molds using precision techniques.

- Apply fiberglass layers and resins to create models with specified dimensions and shapes.

2. Quality Control

Inspect fiberglass models for defects, ensuring they meet quality standards.

- Conduct dimensional checks and surface finish evaluations.

- Identify and rectify any deviations from design specifications.

3. Surface Treatment and Finishing

Prepare fiberglass models for further processing, such as painting, coating, or assembly.

- Sand and smooth fiberglass surfaces to achieve desired finishes.

- Apply primers, paints, or coatings to enhance durability and aesthetics.

4. Tool and Equipment Maintenance

Maintain and troubleshoot fiberglass modeling tools and equipment.

- Ensure proper calibration and operation of sprayers, molds, and other tools.

- Perform routine maintenance and repairs to minimize downtime.

Interview Tips

To ace the interview for a Fiberglass Model Maker position, candidates can follow these tips:

1. Research the Company and Role

Familiarize yourself with the company’s products, services, and industry. Research the specific role and its responsibilities to demonstrate your understanding.

- Review the job description thoroughly and identify key skills and experience requirements.

- Visit the company’s website and social media platforms to learn about its culture and values.

2. Highlight Relevant Skills and Experience

Emphasize your proficiency in fiberglass modeling techniques, including mold making, lamination, and finishing. Showcase your understanding of materials and fabrication processes.

- Provide specific examples of projects where you successfully created fiberglass models that met design specifications.

- Quantify your results whenever possible, using metrics such as dimensional accuracy or surface finish quality.

3. Demonstrate Problem-Solving Abilities

Fiberglass Model Makers often encounter challenges during prototyping and fabrication. Highlight your ability to identify and solve problems effectively.

- Describe instances where you identified defects in fiberglass models and implemented corrective actions.

- Explain how you troubleshoot and repair fiberglass modeling tools and equipment.

4. Prepare Relevant Questions

Asking thoughtful questions during the interview shows your interest in the role and the company. It also gives you an opportunity to clarify expectations and align your skills with their needs.

- Inquire about the company’s ongoing projects and how fiberglass models are utilized.

- Ask about opportunities for professional development and career growth.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Fiberglass Model Maker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.