Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Feltmaker and Weigher position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

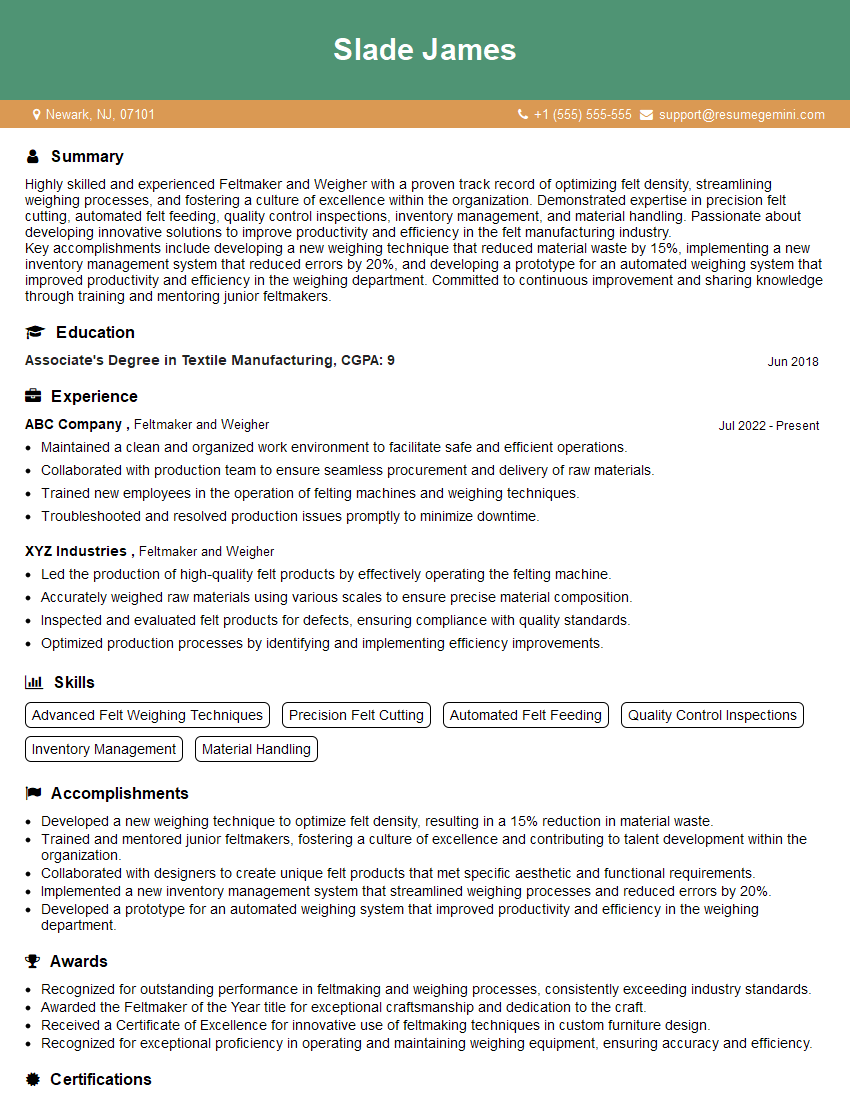

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Feltmaker and Weigher

1. What are the different types of felt and their properties?

There are many different types of felt, each with its own unique properties. Some of the most common types include:

- Wool felt: Made from natural wool fibers, wool felt is soft, warm, and durable. It is often used for making clothing, blankets, and hats.

- Synthetic felt: Made from synthetic fibers, such as polyester or acrylic, synthetic felt is less expensive than wool felt and is often used for making industrial and craft items.

- Needled felt: Made by punching fibers together with needles, needled felt is a strong and durable material that is often used for making carpets and upholstery.

2. What are the different methods used to make felt?

Wet felting

- Involves soaking wool fibers in hot water and then agitating them until they form a mat.

- The mat is then pressed and dried to create felt.

Dry felting

- Involves using a barbed needle to poke wool fibers together.

- The fibers are gradually worked together until they form a dense, felted fabric.

Needle felting

- Involves using a specialized needle to punch fibers together.

- This method is often used to create 3D objects and sculptures.

3. What are the different qualities of felt that make it suitable for different applications?

- Softness: Felt is a soft and pliable material, making it ideal for use in clothing, blankets, and upholstery.

- Warmth: Felt is a good insulator, making it ideal for use in cold weather clothing and blankets.

- Durability: Felt is a durable material that can withstand wear and tear, making it ideal for use in industrial and craft applications.

- Sound absorption: Felt is a good sound absorber, making it ideal for use in noise reduction applications.

4. What are the different types of weighing scales used in the industry and their applications?

- Mechanical scales: Use a spring or balance beam to measure weight.

- Electronic scales: Use a load cell to measure weight and display the result digitally.

- Platform scales: Designed to weigh large objects, such as pallets or vehicles.

- Crane scales: Used to weigh objects that are suspended from a crane.

- Counting scales: Used to count items, such as parts or coins.

5. What are the different factors that can affect the accuracy of a weighing scale?

- Calibration: The scale must be properly calibrated to ensure that it is measuring accurately.

- Temperature: Changes in temperature can affect the accuracy of a scale.

- Vibration: Vibration can cause a scale to give inaccurate readings.

- Wind: Wind can affect the accuracy of a scale by causing it to move or shake.

- Operator error: The operator of the scale can affect the accuracy of the reading by not following the proper procedures.

6. What are the different types of weighing procedures used in the industry?

- Static weighing: The object is placed on the scale and the weight is displayed.

- Dynamic weighing: The object is weighed while it is moving.

- Batch weighing: Multiple objects are weighed together.

- Check weighing: The weight of an object is compared to a known weight.

- Counting: The number of objects is counted.

7. What are the different types of weighing equipment used in the industry and their applications?

- Scales: Used to measure the weight of objects.

- Balances: Used to measure the mass of objects.

- Load cells: Used to measure the weight or force applied to an object.

- Weighbridges: Used to weigh vehicles.

- Hoppers: Used to weigh bulk materials.

8. What are the different types of weighing instruments used in the industry and their applications?

- Analog scales: Use a dial or pointer to indicate the weight.

- Digital scales: Use a digital display to indicate the weight.

- Mechanical scales: Use a spring or balance beam to measure weight.

- Electronic scales: Use a load cell to measure weight and display the result digitally.

9. What are the different types of weighing systems used in the industry and their applications?

- Manual weighing systems: The operator manually reads the weight from a scale or balance.

- Semi-automatic weighing systems: The operator places the object on the scale and the weight is automatically displayed.

- Automatic weighing systems: The entire weighing process is automated, from placing the object on the scale to recording the weight.

10. What are the different types of weighing errors and how can they be prevented?

- Zero error: The scale is not reading zero when there is no object on it.

- Span error: The scale is not reading the correct weight when a known weight is placed on it.

- Linearity error: The scale is not reading the correct weight over the entire weighing range.

- Repeatability error: The scale is not reading the same weight when the same object is placed on it multiple times.

- Temperature error: The scale is not reading the correct weight when the temperature changes.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Feltmaker and Weigher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Feltmaker and Weigher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Feltmaker and Weigher, you will have the following key job responsibilities:

1. Felting

Operate felting machines to produce felt products, such as hats, blankets, and insulation.

- Load raw materials, such as wool, cotton, or synthetic fibers, into the machine.

- Adjust machine settings to control the thickness and density of the felt.

2. Weighing

Weigh and measure raw materials and finished products to ensure they meet specifications.

- Use scales, balances, and other measuring devices to determine weight and dimensions.

- Record weights and measurements, and report any discrepancies to supervisors.

3. Inspecting

Inspect felt products for defects, such as holes, tears, or uneven thickness.

- Identify and mark defective products.

- Report defects to supervisors or quality control personnel.

4. Cleaning and Maintenance

Clean and maintain felting machines and other equipment to ensure proper operation.

- Lubricate and adjust machines as needed.

- Perform routine maintenance tasks, such as cleaning filters and replacing belts.

Interview Tips

To help you ace your interview for the position of Feltmaker and Weigher, here are some tips:

1. Research the company and the role

Take the time to learn about the company’s history, products, and culture. This will show the interviewer that you’re interested in the position and that you’ve taken the time to prepare for the interview.

- Visit the company’s website.

- Read articles and news stories about the company.

- Talk to people in your network who work for the company.

2. Highlight your relevant skills and experience

In your interview, be sure to emphasize the skills and experience that are most relevant to the position of Feltmaker and Weigher. These skills may include:

- Experience operating felting machines.

- Experience weighing and measuring materials.

- Experience inspecting products for defects.

- Experience cleaning and maintaining equipment.

3. Be prepared to answer questions about your experience

The interviewer will likely ask you questions about your experience as a Feltmaker and Weigher. Be prepared to answer questions about:

- Your experience operating different types of felting machines.

- Your experience weighing and measuring materials.

- Your experience inspecting products for defects.

- Your experience cleaning and maintaining equipment.

4. Be prepared to answer questions about your qualifications

The interviewer will also likely ask you questions about your qualifications for the position of Feltmaker and Weigher. Be prepared to answer questions about:

- Your education and training.

- Your work experience.

- Your skills and abilities.

- Your reasons for wanting the position.

5. Be prepared to ask questions

At the end of the interview, the interviewer will likely ask you if you have any questions. This is your opportunity to learn more about the position and the company. Be prepared to ask questions about:

- The company’s culture.

- The company’s growth plans.

- The position’s responsibilities.

- The company’s benefits package.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Feltmaker and Weigher role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.