Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Flange Turner interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Flange Turner so you can tailor your answers to impress potential employers.

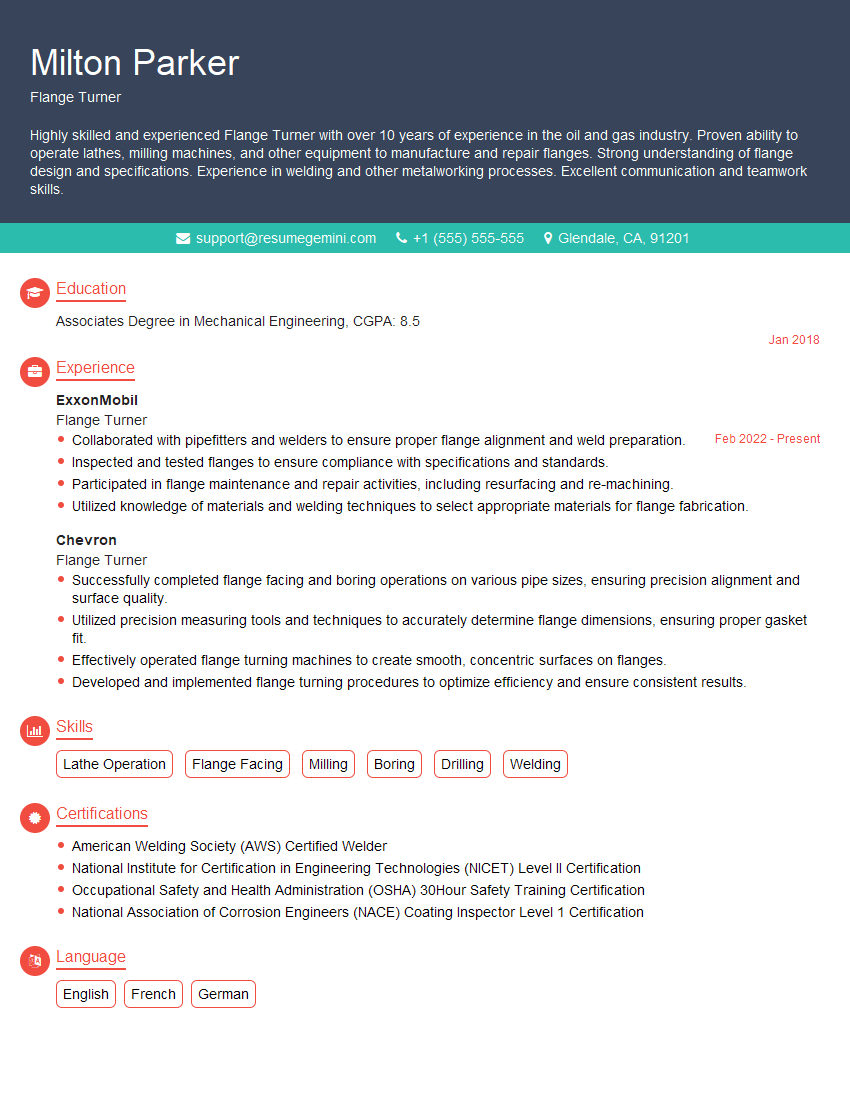

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Flange Turner

1. What is the difference between a flange and a pipe fitting?

A flange is a flat metal disk with holes around the perimeter for bolting to another flange. A flange is used to connect two pipes or tubes together. A pipe fitting is a component that changes the direction or size of a pipe. Pipe fittings include elbows, tees, and reducers.

- Flanges are used to connect two pipes or tubes together.

- Pipe fittings are used to change the direction or size of a pipe.

- Flanges are flat metal disks with holes around the perimeter for bolting to another flange.

- Pipe fittings include elbows, tees, and reducers.

2. What are the different types of flanges?

There are many different types of flanges, each with its own specific application. Some of the most common types of flanges include:

- Slip-on flanges

- Weld neck flanges

- Threaded flanges

- Socket weld flanges

- Lap joint flanges

3. How do you choose the right type of flange for a particular application?

The type of flange that is best suited for a particular application will depend on a number of factors, including the pressure, temperature, and flow rate of the fluid. It is important to consult with a qualified engineer to determine the correct type of flange for a specific application.

- Consider the pressure, temperature, and flow rate of the fluid.

- Consult with a qualified engineer to determine the correct type of flange.

4. What are the different materials used to make flanges?

Flanges can be made from a variety of materials, including:

- Carbon steel

- Stainless steel

- Alloy steel

- Nickel alloys

- Titanium

5. How are flanges manufactured?

Flanges are manufactured using a variety of processes, including:

- Forging

- Casting

- Machining

- Rolling

6. What are the different standards for flanges?

There are a number of different standards for flanges, including:

- ANSI B16.5

- ASME B16.47

- DIN 2501

- JIS B2220

7. What are the safety considerations when working with flanges?

Flanges can be dangerous if they are not handled properly. Some of the safety considerations when working with flanges include:

- Wear appropriate safety gear, including gloves, safety glasses, and a hard hat.

- Inspect flanges regularly for signs of damage.

- Use proper tools and techniques when installing and removing flanges.

- Follow all safety procedures and regulations.

8. How do you troubleshoot a leaking flange?

There are a number of things that can cause a flange to leak, including:

- Improper installation

- Damage to the flange or gasket

- Excessive pressure or temperature

To troubleshoot a leaking flange, it is important to first identify the source of the leak. Once the source of the leak has been identified, it can be repaired using the appropriate method.

9. What is the importance of using high-quality flanges?

Using high-quality flanges is important for ensuring the safety and reliability of a piping system. High-quality flanges are less likely to fail, which can help to prevent leaks, fires, and explosions.

- Ensures the safety and reliability of a piping system

- Less likely to fail

- Helps to prevent leaks, fires, and explosions

10. What are the latest trends in flange technology?

The latest trends in flange technology include:

- The use of new materials, such as composite materials

- The development of new manufacturing processes

- The use of new design techniques

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Flange Turner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Flange Turner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Flange Turners are responsible for a range of tasks that involve working with and cutting flanges. Their primary duty is to ensure the accuracy and precision of flange dimensions, facilitating the effective connection of various components within a system.

1. Flange Cutting

Flange Turners utilize specialized machinery, such as CNC (Computer Numerical Control) lathes or plasma cutters, to cut flanges to the required specifications. This involves setting up the machine, selecting the correct cutting parameters, and monitoring the cutting process to achieve the desired shape and dimensions.

2. Flange Inspection

After cutting, Flange Turners thoroughly inspect the flanges to ensure conformity with the specified tolerances and quality standards. They visually examine the flanges for any defects or imperfections, such as cracks, burrs, or surface irregularities.

3. Flange Shaping

Flange Turners may also be responsible for shaping flanges through processes like bending, rolling, or forging. This involves using specialized equipment or hand tools to manipulate the flange into the desired shape.

4. Flange Fitting

Once the flanges are cut and shaped, Flange Turners work with other technicians to assemble and fit them into the system. They ensure proper alignment, tighten bolts or other fasteners, and verify the integrity of the connection.

Interview Tips

To help candidates ace the interview for a Flange Turner position, here are some key preparation tips and hacks:

1. Research the Job Description and Company

Familiarize yourself with the specific requirements of the job description and the background of the company. This will enable you to tailor your answers to the interviewer’s questions and demonstrate your understanding of the role and its responsibilities.

2. Highlight Your Technical Skills and Experience

Emphasize your proficiency in operating CNC lathes, plasma cutters, and other flange-cutting machinery. Provide specific examples of projects or situations where you successfully used these skills to produce accurate and precise flange dimensions.

3. Demonstrate Your Attention to Detail and Quality Control

Flange Turners must have a keen eye for detail and a commitment to maintaining high quality standards. Highlight your attention to precision and your ability to work meticulously to ensure the accuracy and integrity of your work.

4. Show Your Teamwork and Communication Skills

In addition to technical skills, Flange Turners often work as part of a team. Emphasize your ability to communicate effectively, collaborate with others, and contribute to the success of a project.

5. Prepare Questions for the Interviewer

Asking relevant questions during the interview demonstrates your interest in the position and the company. Prepare thoughtful questions about the role, the work environment, and the company’s goals. This will allow you to gather additional information and show your enthusiasm for the opportunity.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Flange Turner role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.