Feeling lost in a sea of interview questions? Landed that dream interview for Flexographic Press Plate Setter but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Flexographic Press Plate Setter interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

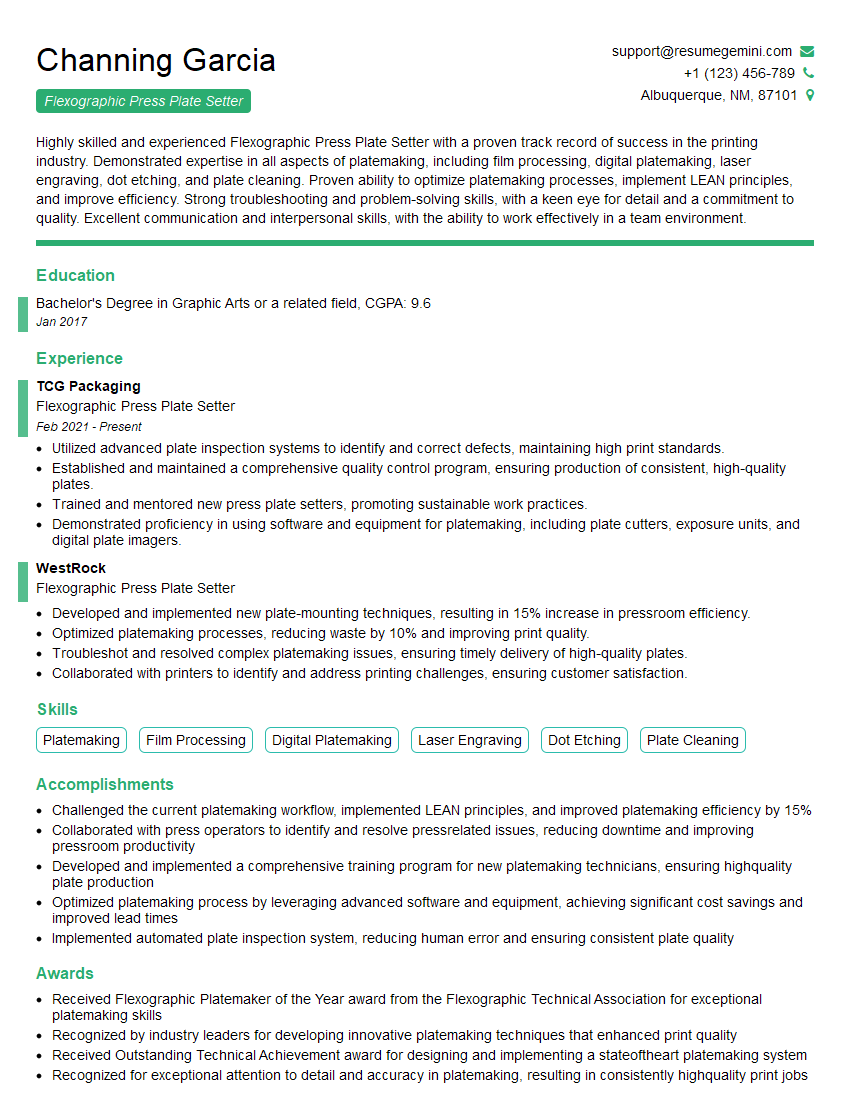

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Flexographic Press Plate Setter

1. Describe the process of mounting a flexographic printing plate onto the plate cylinder.

The process of mounting a flexographic printing plate onto the plate cylinder involves several steps:

- Clean the plate cylinder to remove any dust, debris, or oil.

- Apply a thin layer of mounting tape to the plate cylinder.

- Carefully align the printing plate with the plate cylinder and press it into place.

- Use a roller to apply even pressure across the plate to ensure secure adhesion.

- Trim any excess mounting tape around the edges of the plate.

2. How do you determine the correct tension for a flexographic printing plate?

Checking the Plate Tension

- Use a tensiometer to measure the tension of the plate in pounds per inch (ppi).

- The ideal tension varies depending on the plate material and thickness, but is typically between 15-25 ppi.

Adjusting the Tension

- If the tension is too high, loosen the plate clamps and gently re-tension the plate.

- If the tension is too low, tighten the plate clamps and re-tension the plate.

3. What are the common defects that can occur during flexographic plate making?

- Blistering: Air bubbles trapped between the plate and the cylinder.

- Cracking: Breaks in the plate surface.

- Delamination: Separation of the plate layers.

- Dot gain: Excessive spread of the ink dots resulting in loss of resolution.

- Slurring: Distortion of the ink dots causing blurry print.

4. How do you troubleshoot a flexographic printing press that is experiencing ink smearing?

- Check the ink viscosity and adjust if necessary.

- Inspect the printing plate for damage or wear and replace if needed.

- Clean the impression cylinder and anilox roll to remove any ink buildup.

- Verify that the doctor blade is properly adjusted and making good contact with the anilox roll.

- Increase the press speed to reduce the dwell time of the ink on the plate.

5. What are the safety precautions that you should follow when working with flexographic printing plates?

- Wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and a face mask.

- Handle plates with care to avoid cuts or punctures.

- Use sharp tools carefully and dispose of them properly.

- Keep the work area clean and free of tripping hazards.

- Follow the manufacturer’s instructions for handling and disposing of plates.

6. Describe the different types of flexographic printing plates and their applications.

- Digital plates: Computer-to-plate (CTP) technology, high resolution, suitable for short to medium runs.

- Photopolymer plates: Light-sensitive, flexible, offer good print quality for medium to long runs.

- Rubber plates: Durable, chemically etched, suitable for long runs and abrasive substrates.

- Letterpress plates: Raised printing surface, used for embossing and specialty applications.

7. Explain the role of the anilox roll in the flexographic printing process.

The anilox roll is a critical component of the flexographic printing process:

- Transfers ink from the ink fountain to the printing plate.

- Controls the ink flow and determines the ink thickness on the plate.

- The pattern of the anilox roll cells (volume, shape, and angle) affects the ink transfer and print quality.

8. What are the challenges associated with printing on flexible packaging materials?

- Substrate variations: Different materials have varying properties, requiring adjustments in printing parameters.

- Web tension: Maintaining consistent web tension is crucial for good print registration and quality.

- Ink adhesion: Ensuring proper ink adhesion on flexible substrates can be challenging.

- Environmental conditions: Temperature and humidity can affect the printing process and ink performance.

9. Describe your experience in using prepress software for flexographic plate making.

- Software proficiency: Name specific software and describe your level of expertise.

- Workflow management: Explain your understanding of the prepress workflow, including file preparation, image editing, and plate output.

- Color management: Discuss your knowledge of color profiles, ink libraries, and color accuracy in flexographic printing.

10. How do you stay updated with the latest advancements in flexographic printing technology?

- Industry events: Attend trade shows and conferences to learn about new technologies and trends.

- Technical publications: Read industry magazines, articles, and whitepapers to stay informed.

- Online resources: Utilize websites, forums, and social media to connect with experts and gather information.

- Networking: Engage with colleagues and industry professionals to share knowledge and best practices.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Flexographic Press Plate Setter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Flexographic Press Plate Setter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Flexographic Press Plate Setter is responsible for preparing and maintaining the printing plates used in the flexographic printing process. This involves a variety of tasks, including:

1. Preparing printing plates

The Flexographic Press Plate Setter is responsible for preparing the printing plates that will be used on the flexographic printing press. This involves several steps, including:

- Cleaning the plates

- Coating the plates with a light-sensitive emulsion

- Exposing the plates to light through a film positive

- Developing the plates in a chemical solution

- Inspecting the plates for defects

2. Maintaining printing plates

The Flexographic Press Plate Setter is also responsible for maintaining the printing plates. This includes:

- Cleaning the plates after each use

- Inspecting the plates for wear and tear

- Repairing or replacing damaged plates

3. Troubleshooting printing problems

The Flexographic Press Plate Setter may also be responsible for troubleshooting printing problems. This may involve:

- Identifying the cause of the problem

- Making adjustments to the printing press

- Replacing defective plates

4. Working with other members of the printing team

The Flexographic Press Plate Setter works with other members of the printing team, including the press operator, the ink mixer, and the bindery operator. They must be able to communicate effectively with each other and work together to produce high-quality printed products.

Interview Tips

Preparing for your interview for a Flexographic Press Plate Setter position can help you make a great impression on the hiring manager and increase your chances of getting the job. Here are a few tips to help you prepare:

1. Research the company and the position

Before your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture, goals, and needs, as well as the specific responsibilities of the position. You can find information about the company on their website, in industry publications, and through online job boards.

2. Practice answering common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice answering these questions in advance so that you can deliver clear and concise responses during your interview.

3. Be prepared to talk about your experience and skills

The interviewer will want to know about your experience and skills in flexographic printing. Be prepared to discuss your experience in preparing and maintaining printing plates, troubleshooting printing problems, and working with other members of the printing team. You should also be able to provide examples of your work that demonstrate your skills and abilities.

4. Ask questions

At the end of the interview, you will have the opportunity to ask the interviewer questions. This is a good time to ask about the company, the position, and the next steps in the hiring process. Asking thoughtful questions shows that you are interested in the position and that you have taken the time to prepare for your interview.

5. Follow up after the interview

After your interview, it is important to follow up with the interviewer. This could involve sending a thank-you note or email, or calling the interviewer to reiterate your interest in the position. Following up shows that you are still interested in the position and that you appreciate the interviewer’s time.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Flexographic Press Plate Setter, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Flexographic Press Plate Setter positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.