Are you gearing up for an interview for a Forming Process Line Worker position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Forming Process Line Worker and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

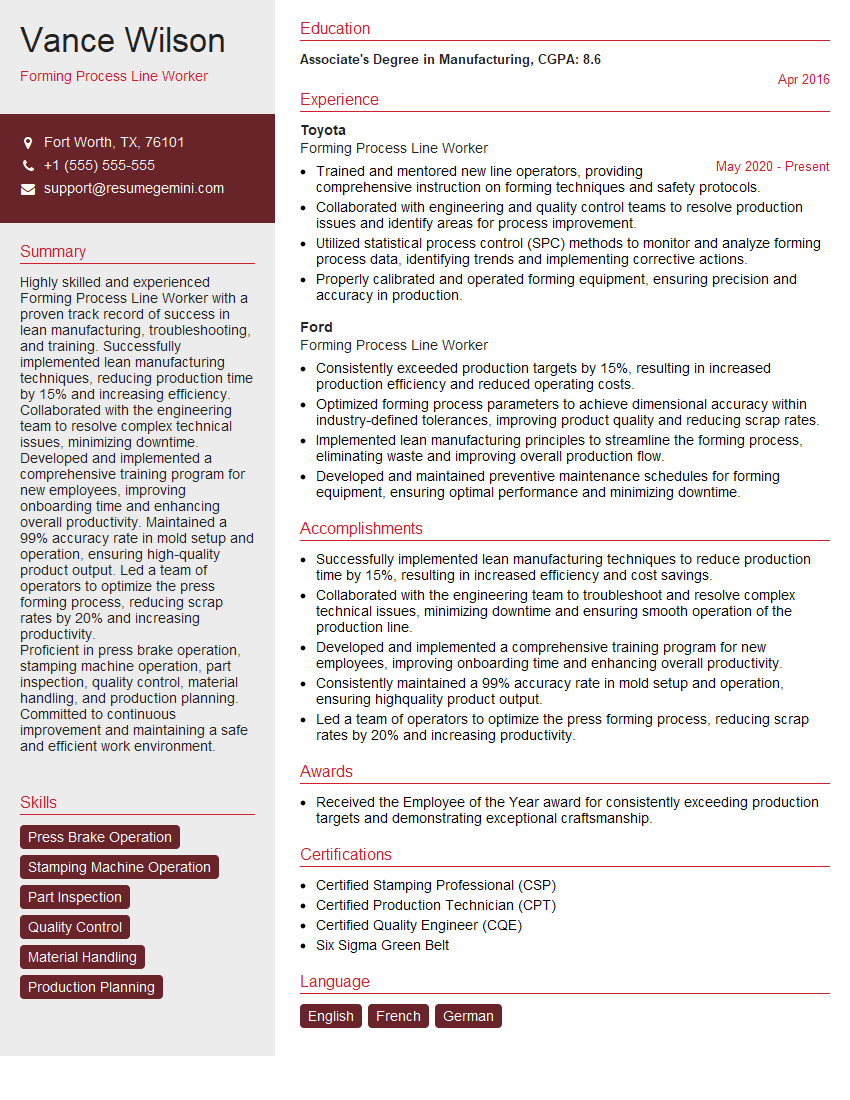

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Forming Process Line Worker

1. Describe the process of forming metal sheets using a press brake.

In the press brake forming process, metal sheets are bent into desired shapes using a press brake machine. The process involves several steps:

- Bending die selection: The appropriate bending die is selected based on the desired bend angle and material thickness.

- Sheet positioning: The metal sheet is placed on the bending die and aligned correctly.

- Punch selection: The punch is selected to match the shape and size of the desired bend.

- Bending: The punch applies pressure to the metal sheet, causing it to bend along the edge of the bending die.

- Clamping: Clamps are used to hold the metal sheet in place during the bending process.

- Springback compensation: After bending, the metal sheet tends to spring back slightly. To compensate for this, the punch is over-bent to ensure the desired bend angle is achieved.

2. Explain how to calculate the bend radius for a given material thickness and bend angle.

Formula:

Bend Radius (R) = (Material Thickness (t) x Bend Factor (K)) / Cosine (Bend Angle (α)/2)

Example:

To calculate the bend radius for a 1mm thick steel sheet bent to a 90-degree angle, using a bend factor of 0.5:

R = (1mm x 0.5) / Cosine (90/2) = 1mm

3. Describe the different types of press brakes and their applications.

There are several types of press brakes, each with its own applications:

- Mechanical press brakes: Use a flywheel and clutch to generate the bending force.

- Hydraulic press brakes: Use hydraulic cylinders to apply the bending force, providing greater precision and control.

- CNC press brakes: Computer-controlled press brakes that offer high accuracy, repeatability, and automation.

- Tandem press brakes: Combine multiple press brakes to handle longer sheets.

4. What are the safety precautions that should be followed while operating a press brake?

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and hearing protection.

- Inspect the press brake and tooling before use to ensure they are in good working condition.

- Clear the work area of any obstructions or debris.

- Keep hands and fingers away from the bending area.

- Never operate the press brake with the guards removed or disabled.

- Follow lockout/tagout procedures when servicing or repairing the press brake.

5. Describe the role of tooling in the press brake forming process.

Tooling plays a crucial role in the press brake forming process:

- Bending die: Supports the metal sheet during bending and determines the bend angle.

- Punch: Applies pressure to the metal sheet to create the bend.

- Clamps: Hold the metal sheet in place during the bending process.

- Shims: Used to adjust the height of the bending die or punch as needed.

6. How do you ensure the quality of formed parts?

- Inspection: Visually inspect formed parts for any defects such as cracks, scratches, or burrs.

- Measurement: Use measuring tools such as calipers or a coordinate measuring machine (CMM) to ensure the parts meet specified dimensions.

- Documentation: Keep records of inspection and measurement results to maintain quality control.

- Continuous improvement: Identify areas for improvement in the forming process and implement corrective actions.

7. What are the potential challenges in press brake forming, and how do you address them?

- Material variations: Different materials may require adjustments in tooling or bending parameters.

- Springback: Compensating for springback by over-bending or using specialized tooling.

- Tool wear: Regular inspection and maintenance of tooling to ensure optimal performance.

- Operator error: Providing proper training and implementing safety measures to minimize errors.

8. Describe your experience in troubleshooting and resolving issues with press brakes.

I have experience in troubleshooting and resolving various issues with press brakes:

- Diagnosed and repaired mechanical problems such as hydraulic leaks or electrical faults.

- Identified and adjusted tooling to resolve bending defects or improve part quality.

- Analyzed and optimized bending parameters to reduce cycle times and improve efficiency.

- Collaborated with maintenance technicians to ensure proper maintenance and calibration of the press brake.

9. Explain your understanding of the principles of lean manufacturing and how it can be applied to press brake forming.

Lean manufacturing focuses on eliminating waste and improving efficiency:

- Setup reduction: Minimizing downtime during setup and changeovers.

- Flow improvement: Optimizing the flow of materials and parts through the forming process.

- Pull system: Producing parts only when they are needed.

- Continuous improvement: Regularly identifying and eliminating waste and inefficiencies.

10. How do you stay up-to-date with the latest technologies and best practices in press brake forming?

- Attend industry conferences and trade shows.

- Read technical journals and articles.

- Participate in online forums and discussion groups.

- Seek training and certification opportunities.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Forming Process Line Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Forming Process Line Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Forming Process Line Workers are responsible for operating and maintaining equipment used in the forming process, which involves shaping metal into desired forms.

1. Equipment Operation

Operate a variety of forming equipment, such as presses, brakes, and shears, to shape metal into desired dimensions and configurations.

- Set up and adjust equipment according to specifications.

- Monitor equipment performance and make necessary adjustments to ensure optimal operation.

2. Material Handling

Handle and move raw materials, semi-finished products, and finished products throughout the forming process.

- Load and unload materials from equipment.

- Inspect materials for defects and ensure they meet quality standards.

3. Quality Control

Check the quality of formed products and identify any defects.

- Conduct visual inspections and use measuring tools to verify dimensions and tolerances.

- Report any quality issues to supervisors and take corrective actions.

4. Process Improvement

Participate in continuous improvement initiatives to enhance the efficiency and effectiveness of the forming process.

- Identify areas for improvement and suggest solutions.

- Implement process changes and monitor their impact.

Interview Tips

Preparing for an interview as a Forming Process Line Worker is crucial to showcase your qualifications and make a positive impression. Here are some tips to help you ace the interview:

1. Research the Company and Position

Thoroughly research the company and the specific position you are applying for. Understand their industry, products, and the role’s responsibilities. This knowledge will help you answer questions intelligently and demonstrate your interest in the company.

- Visit the company’s website and social media pages.

- Read industry articles and news to stay informed about the company’s recent developments.

2. Highlight Relevant Skills and Experience

Emphasize skills and experience that are directly relevant to the job requirements. Quantify your accomplishments whenever possible to provide concrete evidence of your abilities. Highlight your technical skills in operating forming equipment, handling materials, and maintaining quality standards.

- Use the STAR method (Situation, Task, Action, Result) to describe your experiences.

- Provide specific examples of projects or tasks that demonstrate your capabilities.

3. Demonstrate Safety Knowledge

Safety is paramount in manufacturing environments. Show that you understand and prioritize safety protocols. Discuss your experience with safety equipment, hazard identification, and emergency procedures. Highlight your commitment to maintaining a safe work environment.

- Explain your knowledge of industry safety standards and best practices.

- Describe your experience with conducting safety inspections and risk assessments.

4. Show Enthusiasm and a Positive Attitude

Convey your enthusiasm for the role and the manufacturing industry. Express your interest in continuous learning and development. Show that you are a team player with a positive attitude. Your enthusiasm and passion can make a lasting impression on the interviewer.

- Share examples of your interest in manufacturing and forming processes.

- Discuss your goals for career growth and professional development.

5. Practice Common Interview Questions

Review common interview questions and prepare your answers. This will help you feel more confident and articulate during the interview. Practice answering questions about your technical skills, experience, and why you are interested in the position.

- Anticipate questions about your knowledge of forming equipment and quality control procedures.

- Prepare an elevator pitch to introduce yourself and highlight your strengths briefly.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Forming Process Line Worker, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Forming Process Line Worker positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.