Are you gearing up for an interview for a Foundry Hand position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Foundry Hand and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

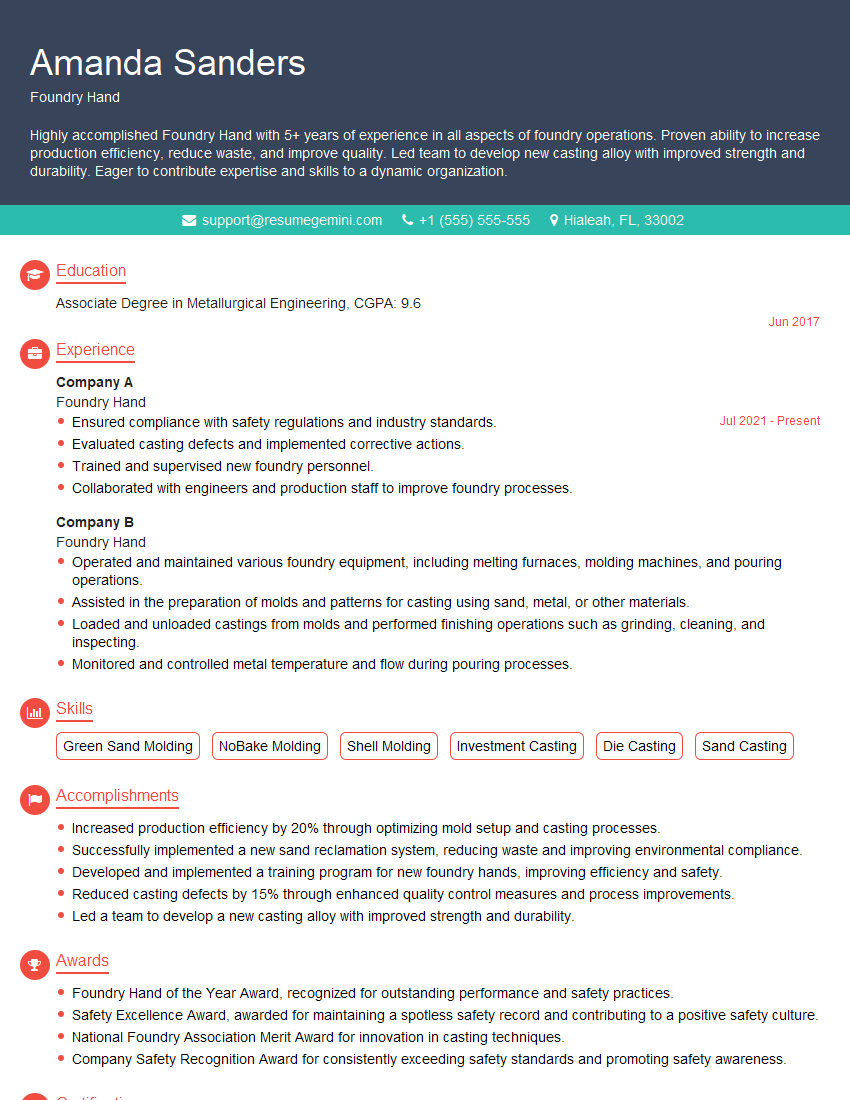

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Foundry Hand

1. What are the primary responsibilities of a Foundry Hand?

As a Foundry Hand, my primary responsibilities include:

- Operate and maintain foundry equipment, such as molding machines, casting machines, and furnaces.

- Follow established procedures for pouring molten metal into molds and ensuring proper cooling and solidification.

- Inspect castings for defects and clean and finish them as required.

- Handle and store materials and equipment safely.

- Maintain a clean and organized work area.

2. Describe the different types of molding processes used in foundries.

Sand Casting

- Green sand molding: Uses moist sand to create molds.

- Dry sand molding: Uses dried sand to create molds that are more suitable for large and complex castings.

- Resin-bonded molding: Uses a resin binder to hold the sand together, resulting in higher mold strength.

Investment Casting

- Lost-wax casting: Uses a wax pattern that is coated with a ceramic slurry and then melted out to create a mold.

- Shell molding: Uses a thin, ceramic shell as the mold.

Die Casting

- Uses a permanent metal die to inject molten metal under high pressure.

- Produces high-volume, precision castings.

3. Explain the importance of pouring temperature when casting molten metal.

The pouring temperature is critical because it affects:

- Fluidity: A higher pouring temperature increases fluidity, allowing the metal to fill the mold more easily.

- Solidification rate: A lower pouring temperature results in a slower solidification rate, which can reduce the risk of defects.

- Grain structure: The pouring temperature can influence the grain structure of the casting, affecting its mechanical properties.

4. Describe the safety precautions that must be taken when working in a foundry.

- Wear personal protective equipment (PPE), including appropriate clothing, gloves, eye protection, and hearing protection.

- Be aware of hot surfaces and molten metal.

- Follow established safety procedures for handling and storing materials and equipment.

- Maintain a clean and organized work area.

- Receive proper training on all equipment and processes.

5. What are the common defects that can occur in castings and how can they be prevented?

- Porosity: Caused by gas bubbles trapped in the metal during solidification. Prevented by using proper pouring techniques and degassing the metal.

- Shrinkage defects: Caused by metal shrinking as it cools. Prevented by using proper gating and risering systems.

- Cold shuts: Caused by molten metal not flowing together properly. Prevented by ensuring sufficient fluidity and pouring temperature.

- Inclusions: Caused by foreign particles entering the molten metal. Prevented by maintaining a clean work area and using proper melting procedures.

6. How do you measure the quality of castings?

- Visual inspection: Checking for surface defects, cracks, and other imperfections.

- Dimensional inspection: Ensuring that the casting meets the specified dimensions.

- Mechanical testing: Testing the casting’s strength, hardness, and other mechanical properties.

- NDT (Non-Destructive Testing): Using methods like X-ray or ultrasonic testing to identify internal defects.

7. What are the advantages and disadvantages of using sand casting compared to die casting?

Sand Casting

Advantages:- Versatility: Can produce castings of various shapes and sizes.

- Lower tooling costs.

- Suitable for small batch production.

- Lower production rates.

- Less precision compared to die casting.

- Higher risk of defects.

Die Casting

Advantages:- High production rates.

- High precision and repeatability.

- Reduced defects.

- Higher tooling costs.

- Limited to smaller and simpler shapes.

- Not suitable for large-scale production.

8. Explain the process of heat treatment in the context of metal casting.

Heat treatment involves heating and cooling castings to achieve desired properties:

- Annealing: Softening the metal by heating it to a high temperature and cooling it slowly.

- Annealing: Softening the metal by heating it to a high temperature and cooling it slowly.

- Normalizing: Increasing strength and hardness by heating the metal to a high temperature and cooling it in still air.

- Tempering: Reducing brittleness and increasing toughness by heating the metal to a lower temperature and cooling it slowly.

9. Describe the role of gating systems in metal casting.

Gating systems control the flow of molten metal into the mold:

- Sprue: Main channel that carries metal from the pouring basin to the mold.

- Runner: Channels that distribute metal to different sections of the mold.

- Gates: Openings where metal enters the mold cavity.

- Risers: Reservoirs of molten metal that feed the casting during solidification to compensate for shrinkage.

10. What are the factors that affect the choice of mold material in metal casting?

- Casting size and complexity: Larger and more intricate castings require stronger mold materials.

- Melting point of the metal: The mold material must withstand the temperature of the molten metal.

- Mold strength and durability: The mold must resist deformation and cracking under the weight of the molten metal.

- Reusability: Some mold materials, such as sand, can be reused multiple times.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Foundry Hand.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Foundry Hand‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Foundry Hands play a crucial role in the production of metal castings. Their key responsibilities encompass various aspects of foundry operations, ensuring the smooth functioning of the facility.

1. Mold Preparation

Foundry Hands prepare molds used in the casting process. This involves:

- Assembling and securing mold boxes

- Applying parting agents to prevent castings from sticking

- Ramming mold boxes with sand or other mold materials

- Creating mold patterns and cores

2. Pouring Molten Metal

Foundry Hands handle molten metal with precision and safety:

- Positioning ladles or crucibles to receive molten metal

- Pouring molten metal into molds

- Controlling pouring temperature and flow rate

- Ensuring mold filling complies with specifications

3. Finishing Processes

After castings solidify, Foundry Hands perform finishing tasks:

- Removing castings from molds

- Cleaning and inspecting castings for defects

- Trimming and grinding excess material

- Applying coatings or treatments

4. Equipment Maintenance

Foundry Hands contribute to equipment upkeep:

- Maintaining mold boxes, ladles, and other foundry equipment

- Performing routine inspections and repairs

- Ensuring equipment is in good working order for efficient production

Interview Tips

To ace the interview for a Foundry Hand position, it’s essential to prepare thoroughly. Here are some tips to help candidates make a positive impression:

1. Research the Company and Role

Research the foundry and the specific job responsibilities. This demonstrates your interest in the position and the company’s operations.

- Visit the company’s website

- Read industry publications

- Connect with foundry professionals on LinkedIn

2. Highlight Relevant Skills and Experience

Emphasize skills and experience that align with the job requirements. For example, mention experience in:

- Mold making

- Pouring molten metal

- Finishing processes

- Equipment maintenance

3. Prepare for Safety Questions

Foundry operations involve potential hazards. Be prepared to discuss your knowledge of safety protocols and experience working in a foundry environment.

- Explain your understanding of proper protective equipment (PPE)

- Share examples of safety practices you’ve followed in previous roles

- Discuss your awareness of potential hazards and how to mitigate them

4. Ask Insightful Questions

Asking thoughtful questions shows your interest and engagement. Prepare questions that demonstrate your knowledge of the industry and the company.

- Ask about the company’s production process

- Inquire about opportunities for training and advancement

- Seek insights into the company’s safety culture

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Foundry Hand interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!