Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Fourdrinier Wire Weaver position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

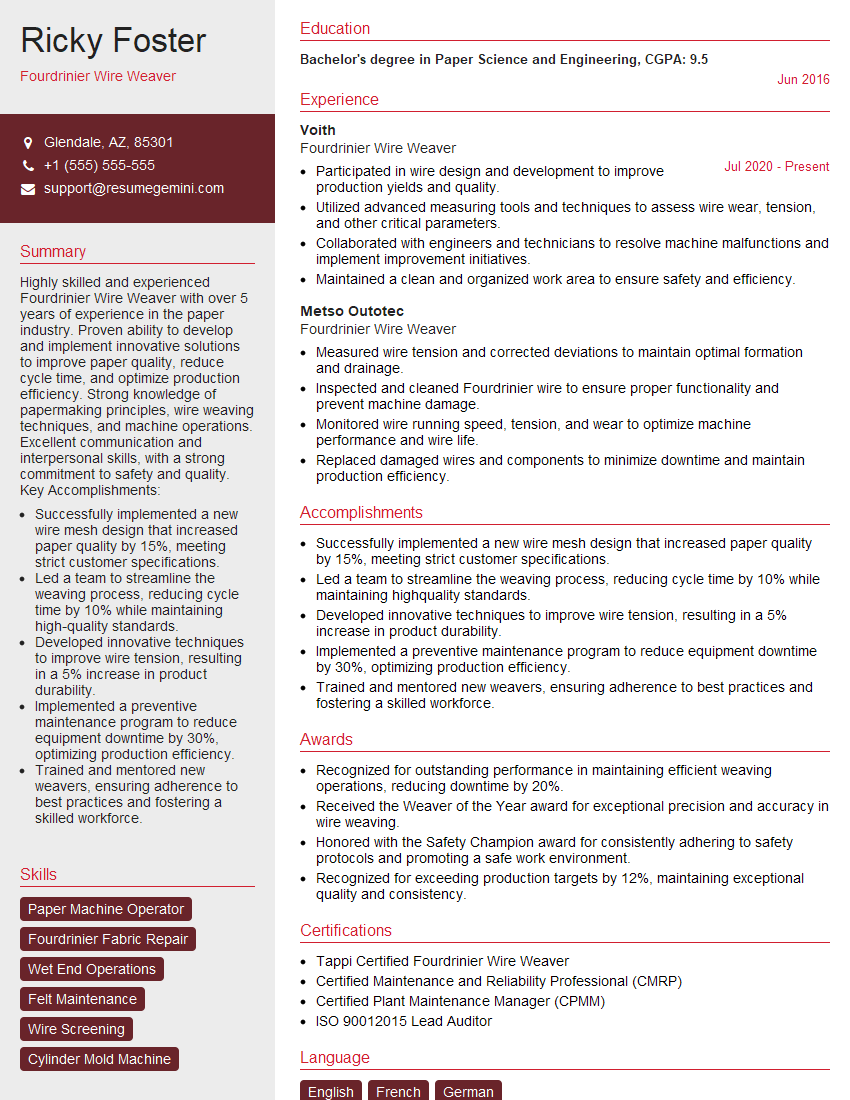

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fourdrinier Wire Weaver

1. Explain the process of Fourdrinier wire weaving?

The process of Fourdrinier wire weaving involves creating a continuous mesh fabric used in papermaking machines. Here’s a detailed explanation of the steps:

- Preparation of Warp Yarns: Long, parallel yarns called warp yarns are wound onto a warp beam, which provides tension and ensures uniform spacing.

- Warping: The warp yarns are passed through a series of guide rollers and tension devices to create a sheet of parallel yarns.

- Shedding: The warp yarns are lifted and separated into two layers, creating a shed or opening.

- Filling or Weft Insertion: Filling or weft yarns are inserted into the shed perpendicular to the warp yarns, interlacing them together.

- Beat-up: A reed or beater is used to push the weft yarns firmly against the previously woven fabric.

- Laying or Shedding: The warp yarns are lifted and separated again to create a new shed, allowing the next weft yarn to be inserted.

- Repeat: The process of shedding, filling insertion, beat-up, and laying is repeated until the desired length of fabric is produced.

2. What are the key factors that affect the quality of Fourdrinier wires?

Material Properties:

- Wire Diameter: Thinner wires create finer mesh apertures, improving paper quality but reducing durability.

- Material Composition: Stainless steel wires offer strength and corrosion resistance, while bronze wires have improved wear resistance.

Weaving Parameters:

- Mesh Count: The number of warp and weft yarns per inch determines the mesh size and openness.

- Weave Pattern: Different weave patterns, such as plain weave or twill weave, affect wire porosity and strength.

Operational Conditions:

- Machine Speed: Higher machine speeds require wires with greater strength and wear resistance.

- Pulp Consistency: The solids content of the paper pulp affects the strain on the wire.

3. How do you determine the correct Fourdrinier wire mesh count for a specific papermaking application?

Determining the correct mesh count involves considering several factors:

- Paper Grade: Different paper grades require specific drainage and retention characteristics, which are influenced by mesh count.

- Machine Speed: Machines operating at higher speeds require wires with finer mesh to handle the increased water flow.

- Pulp Type: The type of pulp used (e.g., chemical vs. mechanical) affects the drainage and filtration properties required.

- Wire Life: Wires with coarser mesh counts tend to have longer lifespans due to reduced wear.

- Cost: Mesh count impacts wire cost, with finer meshes being more expensive.

4. What are the different types of selvages used in Fourdrinier wires, and how do they affect wire performance?

Selvages are the reinforced edges of Fourdrinier wires. They play a vital role in preventing fraying and ensuring stability.

- Plain Selvage: Consists of a single layer of twisted wires, providing basic edge reinforcement.

- Double Selvage: Features two layers of twisted wires, offering increased strength and stability.

- Reinforced Selvage: Utilizes additional reinforcing wires or materials to enhance longevity and resistance to wear.

- Knuckle Selvage: Incorporates a loop-shaped edge that engages with the wire guide on the forming section, improving tracking.

5. Describe the maintenance procedures for Fourdrinier wires to ensure optimal performance and longevity?

Regular maintenance is essential to extend wire life and maintain paper quality:

- Cleaning: Remove debris, such as fibers and pitch, from the wire surface using high-pressure water jets or ultrasonic cleaning.

- Inspection: Regularly examine wires for wear, corrosion, or damage, especially in high-wear areas.

- Repair: Promptly repair any damages to prevent further deterioration and ensure wire integrity.

- Tensioning: Maintain proper tension on the wire to prevent sagging or stretching.

- Lubrication: Apply lubricants to reduce friction and wear on moving parts.

6. How do you troubleshoot common issues encountered with Fourdrinier wires during papermaking?

Common issues and troubleshooting tips:

- Wire Breaks: Check for excessive wear, improper tension, or foreign objects in the pulp.

- Edge Fraying: Ensure proper selvage reinforcement and tension settings.

- Poor Drainage: Verify mesh count and porosity to ensure adequate drainage for the specific paper grade.

- Wire Tracking Problems: Inspect wire guides and knuckle selvages, adjust tension, or consult with machine manufacturer.

- Wear and Corrosion: Monitor wire condition, adjust chemical additives in the pulp, and consider using more durable wire materials.

7. What are the key performance indicators (KPIs) used to evaluate the effectiveness of Fourdrinier wires?

- Wire Life: Measured in operating hours or tons of paper produced.

- Paper Quality: Assessed based on surface smoothness, thickness uniformity, and formation.

- Machine Efficiency: Uptime and production rate are key indicators of wire performance.

- Maintenance Costs: Repair frequency and replacement expenses impact the overall efficiency of the operation.

- Energy Consumption: Wires with optimized mesh count and design can contribute to energy savings.

8. Describe the role of the forming section in a papermaking machine and how Fourdrinier wires contribute to its function?

The forming section is where the paper web is initially formed. Fourdrinier wires play a crucial role in this process:

- Water Drainage: The mesh structure of the wire allows water to drain from the pulp, forming the paper sheet.

- Fiber Retention: The wires retain the papermaking fibers while allowing water to pass through, creating the paper’s structure.

- Sheet Formation: The wire’s surface properties influence the smoothness and uniformity of the paper web.

9. How have advancements in Fourdrinier wire technology improved papermaking efficiency and quality?

- Advanced Materials: New materials, such as high-strength alloys and polymers, have enhanced wire durability and longevity.

- Precision Weaving: Improved weaving techniques have increased mesh accuracy and consistency, resulting in better paper formation.

- Self-Cleaning Designs: Wires with anti-stick surfaces reduce fiber buildup and improve drainage.

- Optimized Mesh Patterns: Customized mesh designs have been developed to meet specific paper grade requirements, improving quality and efficiency.

10. What are the emerging trends and developments in Fourdrinier wire technology that you are excited about?

- Nanotechnology: The use of nanomaterials in wire coatings may enhance surface properties and improve performance.

- Smart Wires: Wires with sensors and monitoring capabilities could provide real-time data on wire conditions and paper quality.

- Sustainable Materials: Bio-based and recyclable materials are being explored for wire manufacturing to reduce environmental impact.

- Additive Manufacturing: 3D printing techniques could enable the production of complex wire designs with improved functionality.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fourdrinier Wire Weaver.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fourdrinier Wire Weaver‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Fourdrinier Wire Weaver is a highly skilled professional responsible for operating and maintaining weaving machines that produce papermaking wire fabric. Their primary duties revolve around ensuring the efficient and productive operation of these machines while maintaining the highest quality standards.

1. Machine Operation

Operate Fourdrinier weaving machines to produce papermaking wire fabric according to specifications.

- Monitor machine performance and make adjustments as needed to maintain optimal operating conditions.

- Troubleshoot and resolve machine malfunctions and ensure timely repairs.

2. Wire Production

Ensure the production of high-quality papermaking wire fabric that meets customer specifications.

- Set up and prepare weaving machines for different wire grades and styles.

- Monitor and control wire tension, density, and weave patterns to achieve desired fabric properties.

3. Quality Control

Conduct regular quality checks on produced wire fabric to ensure adherence to standards.

- Inspect wire fabric for defects, breaks, and other irregularities.

- Report any quality issues and work with team members to resolve them promptly.

4. Maintenance and Repairs

Perform routine maintenance and repairs on weaving machines to ensure smooth operation.

- Inspect and clean machine components to prevent breakdowns.

- Identify and replace worn or damaged parts to maintain machine efficiency.

Interview Tips

To ace a job interview for a Fourdrinier Wire Weaver position, it’s essential to prepare adequately and showcase your skills and experience in the field. Here are some interview tips and hacks to help you make a positive impression:

1. Research the Company and Position

Thoroughly research the company’s history, values, and the specific job requirements. This will help you understand the organization’s culture and tailor your answers to their needs.

2. Highlight Relevant Experience

Emphasize your experience in operating and maintaining Fourdrinier weaving machines. Quantify your accomplishments with specific metrics, such as increased production efficiency or reduced downtime.

3. Demonstrate Technical Knowledge

Be prepared to discuss your understanding of papermaking wire fabric, weaving techniques, and quality control procedures. Use industry-specific terminology and provide examples of your problem-solving abilities.

4. Showcase Quality-Consciousness

Stress your commitment to producing high-quality wire fabric. Explain your attention to detail, ability to identify defects, and procedures for maintaining standards.

5. Display Mechanical Aptitude

Highlight your mechanical aptitude and experience in maintaining and repairing weaving machines. Describe your familiarity with machine components, troubleshooting skills, and preventative maintenance practices.

6. Prepare Industry-Specific Questions

Ask insightful questions related to the papermaking industry, such as advancements in wire fabric technology or sustainability initiatives. This demonstrates your genuine interest and knowledge of the field.

7. Practice Common Interview Questions

Prepare for general interview questions, such as “Tell me about yourself,” “Why are you interested in this position?” and “What are your strengths and weaknesses?” Rehearse your answers to present yourself confidently.

8. Dress Professionally and Arrive on Time

First impressions matter. Dress professionally and arrive punctually for your interview. Maintain a positive and enthusiastic attitude throughout the meeting.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Fourdrinier Wire Weaver interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.