Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Garland Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

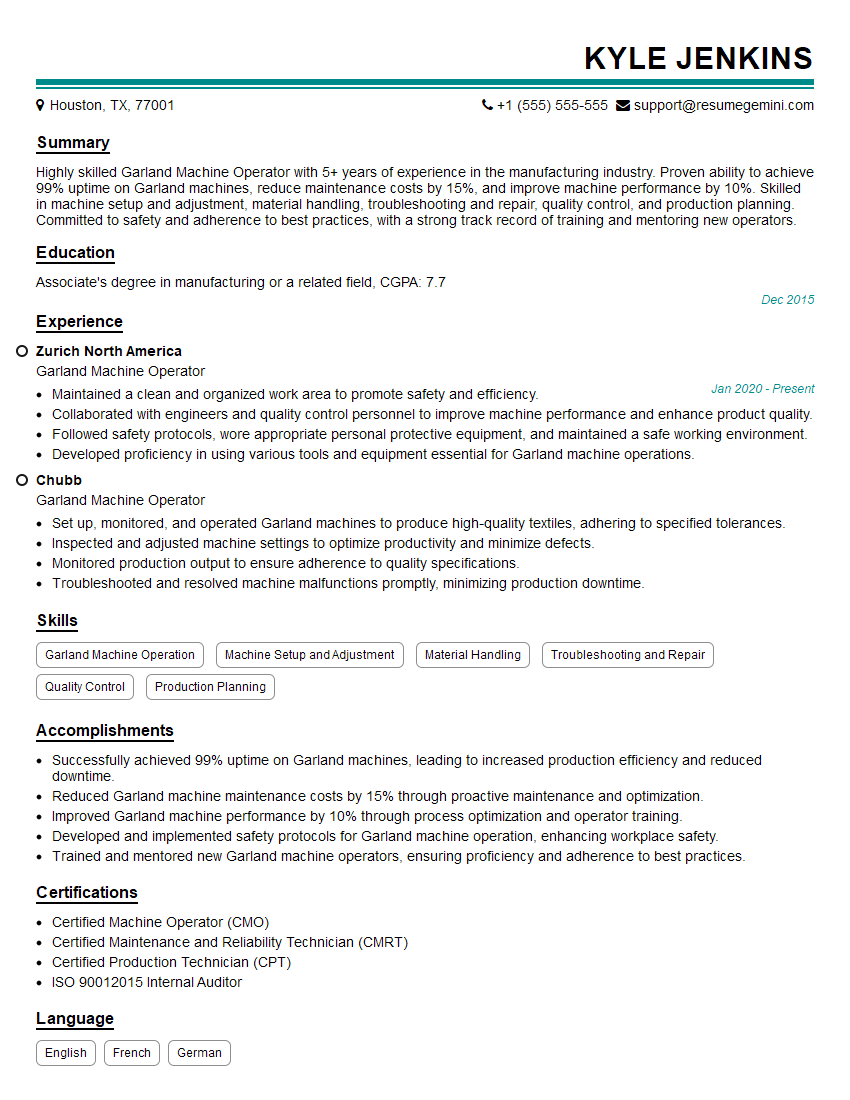

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Garland Machine Operator

1. What are the key responsibilities of a Garland Machine Operator, can you explain?

The primary responsibilities of a Garland Machine Operator include:

- Operating and monitoring Garland machines to produce garlands and other decorative items.

- Ensuring the smooth operation of the machine and identifying potential issues promptly.

- Maintaining the machine, performing regular cleaning, and following established safety protocols.

- Working as part of a team to achieve production targets and deadlines.

- Keeping a clean and organized work area, adhering to quality standards, and following safety regulations.

2. How do you ensure the quality of garlands produced on the machine, and what quality checks do you perform?

- Regularly inspecting the garlands during production to identify any defects or inconsistencies.

- Checking the tension, color consistency, and overall appearance of the garlands.

- Performing spot checks throughout the production process to ensure adherence to specifications.

- Consulting with supervisors or quality control personnel to resolve any quality concerns.

- Maintaining records of quality checks and reporting any issues promptly.

3. What are the common maintenance tasks required for a Garland Machine, and how do you prioritize these tasks?

- Cleaning the machine regularly to remove any debris or dust that could affect performance.

- Inspecting and lubricating moving parts to prevent wear and tear.

- Tightening screws and bolts to ensure stability and prevent vibrations.

- Calibrating the machine to maintain accuracy and precision.

- Prioritizing maintenance tasks based on the frequency of use, potential impact on production, and safety considerations.

4. How do you troubleshoot common problems that may arise while operating a Garland Machine?

When troubleshooting common problems with a Garland Machine, I follow these steps:

- Identifying the problem accurately by observing symptoms and gathering information.

- Referring to the machine manual or seeking guidance from experienced operators.

- Checking for loose connections, damaged parts, or improper settings.

- Performing necessary adjustments or repairs to resolve the issue.

- Testing the machine after troubleshooting to ensure it operates correctly.

5. What is your approach to working as part of a team in a fast-paced production environment?

In a fast-paced production environment, I believe in the following approach to teamwork:

- Effective communication: Regularly sharing information, updates, and any challenges faced with team members.

- Collaboration: Working together to achieve common goals, supporting each other, and sharing knowledge.

- Respect and understanding: Recognizing and valuing the contributions of each team member, fostering a positive and respectful work environment.

- Flexibility: Adapting to changes in production demands, taking on different tasks as needed, and supporting team members when necessary.

- Continuous improvement: Sharing ideas, suggesting process enhancements, and actively seeking ways to improve team performance.

6. How do you stay up-to-date with the latest advancements and best practices in Garland Machine operation?

- Attending industry workshops, conferences, or training sessions.

- Reading trade publications and technical articles.

- Consulting with other Garland Machine Operators or experts in the field.

- Seeking feedback from supervisors and incorporating it into my practices.

- Actively participating in discussions or online forums related to Garland Machine operation.

7. What are some innovative techniques or ideas you have implemented to improve Garland Machine efficiency or productivity?

- Developed a preventative maintenance schedule to reduce downtime and improve machine longevity.

- Optimized production processes by implementing lean manufacturing principles, resulting in reduced waste and increased output.

- Suggested modifications to the machine’s design to enhance its performance and ease of operation.

- Trained new operators on best practices and efficient techniques, leading to improved overall productivity.

- Collaborated with engineers to develop automated quality control measures, ensuring consistent garland quality and reducing manual inspection time.

8. How do you ensure safety while operating a Garland Machine and working in a production environment?

- Adhering to all established safety protocols and guidelines.

- Wearing appropriate safety gear, including gloves, safety glasses, and ear protection.

- Maintaining a clean and organized work area to prevent tripping hazards or accidents.

- Inspecting the machine regularly and reporting any potential safety concerns promptly.

- Following proper lifting techniques and seeking assistance when handling heavy materials.

9. How do you handle situations where the production targets are not met, and what steps do you take to improve performance?

- Analyzing the reasons for not meeting production targets, such as machine issues, material shortages, or process inefficiencies.

- Discussing with supervisors and team members to identify areas for improvement.

- Implementing corrective actions, such as adjusting machine settings, optimizing processes, or requesting additional resources.

- Monitoring progress and making further adjustments as needed to achieve desired production levels.

- Learning from past experiences and proactively identifying potential challenges to prevent future shortfalls.

10. How do you stay motivated and maintain a positive attitude in a repetitive production environment?

- Setting personal goals and challenging myself to achieve them.

- Focusing on the quality of my work and taking pride in producing high-quality garlands.

- Engaging in continuous learning and seeking ways to improve my skills and knowledge.

- Interacting with colleagues and maintaining a positive and supportive work environment.

- Recognizing and celebrating successes, both individual and team-based.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Garland Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Garland Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Garland Machine Operator is responsible for overseeing the operation and maintenance of a garland machine, a specialized piece of equipment used in the production of garlands and other decorative items.

1. Garland Production

Operate the garland machine to produce garlands according to specified designs, patterns, and dimensions.

- Set up and calibrate the machine, ensuring accurate and efficient garland production.

- Monitor the garland-making process, including material flow, tension, and quality control.

2. Machine Maintenance

Perform routine maintenance and troubleshooting on the garland machine to ensure optimal performance.

- Inspect and clean machine components, identifying and addressing potential issues.

- Lubricate, adjust, and repair machine parts as needed, minimizing downtime.

3. Quality Control

Inspect garlands produced by the machine, ensuring they meet established quality standards.

- Check for defects in material, construction, and appearance.

- Adjust machine settings and parameters as necessary to maintain product quality.

4. Production Support

Assist other team members in tasks related to garland production and machine operation.

- Provide technical support and training to fellow operators.

- Collaborate with quality control personnel to identify and resolve production issues.

Interview Tips

To ace an interview for a Garland Machine Operator position, it is crucial to demonstrate your technical proficiency, problem-solving abilities, and attention to detail. Here are some interview tips to help you prepare:

1. Research the Company and the Industry

Familiarize yourself with the company’s mission, values, and product offerings. Research the industry trends and the latest technologies used in garland production.

2. Practice Your Technical Skills

Review the key job responsibilities, especially those related to garland machine operation and maintenance. Practice describing your experience in these areas, highlighting your ability to troubleshoot and resolve technical issues.

3. Showcase Your Quality Control Expertise

Emphasize your understanding of quality control standards and your experience in inspecting products. Provide examples of how you have identified and resolved quality issues in previous roles.

4. Highlight Your Team-Oriented Approach

Garland Machine Operators often work as part of a team. Highlight your communication skills, willingness to collaborate, and ability to support your colleagues.

5. Prepare for Common Interview Questions

Anticipate common interview questions such as “Tell me about your experience with garland machine operation” or “Describe a time when you had to resolve a production issue.” Prepare concise and specific answers that demonstrate your knowledge and skills.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Garland Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.