Are you gearing up for a career in Glass Unloading Equipment Tender? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Glass Unloading Equipment Tender and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

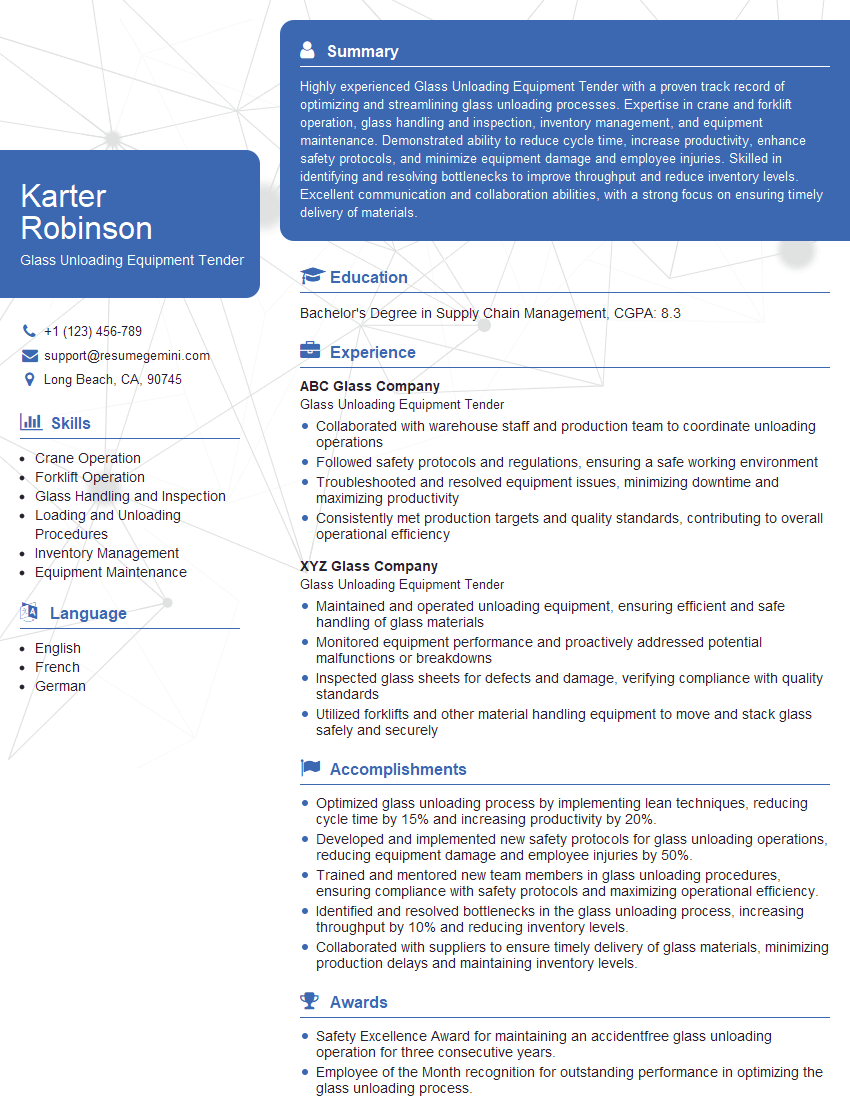

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Glass Unloading Equipment Tender

1. Describe the key components of a glass unloading equipment tender?

The following are the key components of a glass unloading equipment tender:

- Unloading Platform: The platform where the glass is unloaded from the truck/trailer.

- Conveyor system: The system that transports the glass from the unloading platform to the storage area.

- Storage system: The area where the glass is stored before it is used in production.

- Electrical system: The electrical components that power and control the equipment.

- Hydraulic system: The hydraulic components that power the movement of the equipment.

2. How do you ensure the safe operation of glass unloading equipment?

Adhering to Safety Protocols:

- Follow all safety guidelines and regulations established by the manufacturer and industry standards.

- Conduct regular inspections and maintenance of the equipment to ensure it is in good working order.

Proper Handling Techniques:

- Use appropriate personal protective equipment (PPE), such as safety glasses and gloves, when handling glass.

- Operate the equipment cautiously and avoid sudden movements or excessive force.

Training and Supervision:

- Provide comprehensive training to operators on the safe handling and operation of the equipment.

- Supervise operators, especially during critical operations, to ensure adherence to safety protocols.

3. What is the role of preventive maintenance in ensuring the optimal performance of Glass Unloading Equipment?

Preventive maintenance plays a crucial role in ensuring optimal performance and longevity of Glass Unloading Equipment:

- Regular Inspections: Conduct scheduled inspections to identify potential issues and address them promptly.

- Scheduled Servicing: Adhere to recommended maintenance schedules, including lubrication, filter replacements, and adjustments.

- Condition Monitoring: Monitor the equipment’s performance and identify any deviations from normal operating parameters.

- Component Replacement: Replace worn or damaged components proactively to prevent breakdowns and ensure smooth operation.

- Record Keeping: Maintain detailed maintenance records to track inspections, repairs, and replacements for future reference.

4. Describe the various types of glass that can be handled by Glass Unloading Equipment and their specific requirements?

Glass Unloading Equipment is designed to handle different types of glass, each with its unique requirements:

- Float Glass: Common type of glass used in windows, mirrors, and tabletops. Requires careful handling to prevent scratches.

- Tempered Glass: Stronger and more durable than float glass. Used in applications such as shower doors and car windows. Needs specialized equipment for unloading.

- Laminated Glass: Consists of two or more layers of glass bonded together. Offers increased safety and soundproofing. Requires precise handling to avoid delamination.

- Coated Glass: Has a special coating applied to enhance properties such as solar control, privacy, or energy efficiency. Needs careful handling to protect the coating.

- Insulated Glass Units (IGUs): Consist of two or more glass panes separated by a spacer. Used for improved insulation and noise reduction. Require specialized equipment for unloading and installation.

5. What factors should be considered when selecting Glass Unloading Equipment?

When selecting Glass Unloading Equipment, it is essential to consider the following factors:

- Glass Type and Size: Determine the types and sizes of glass that need to be handled to ensure compatibility with the equipment.

- Volume and Capacity: Consider the volume and weight of glass that will be unloaded to select equipment with sufficient capacity.

- Unloading Environment: Assess the unloading area’s size, accessibility, and any potential obstacles to ensure the equipment can operate efficiently.

- Safety Features: Prioritize equipment with safety features such as anti-slip surfaces, emergency stop buttons, and operator visibility.

- Durability and Maintenance: Choose equipment made from durable materials and consider the maintenance requirements and availability of spare parts.

6. Describe the key maintenance procedures required for Glass Unloading Equipment?

Regular maintenance is essential for Glass Unloading Equipment to ensure optimal performance and longevity:

- Daily Inspections: Check for any visible damage, leaks, or loose connections and address them promptly.

- Lubrication: Lubricate moving parts according to the manufacturer’s recommendations to minimize friction and wear.

- Filter Replacements: Replace filters regularly to maintain the cleanliness of hydraulic and electrical systems.

- Electrical System Checks: Inspect wiring, connections, and switches for any damage or loose contacts.

- Hydraulic System Maintenance: Check hydraulic fluid levels, inspect hoses and fittings for leaks, and bleed the system as needed.

7. What are the common troubleshooting steps for Glass Unloading Equipment?

When troubleshooting Glass Unloading Equipment, follow these steps:

- Identify the Issue: Observe the equipment and identify any abnormal noises, movements, or error messages.

- Check Safety Features: Ensure that all safety features are activated and functioning correctly.

- Inspect Hydraulic System: Check for leaks, low fluid levels, or any unusual noises in the hydraulic system.

- Examine Electrical Connections: Inspect wiring, connections, and switches for any damage or loose contacts.

- Review Maintenance History: Refer to maintenance records to identify any recent changes or repairs that may be related to the issue.

8. Describe the importance of operator training for Glass Unloading Equipment?

Operator training is crucial for Glass Unloading Equipment to ensure safety, efficiency, and optimal performance:

- Safety Protocols: Train operators on proper handling techniques, safety measures, and emergency procedures.

- Equipment Operation: Provide thorough training on the equipment’s controls, functions, and operating limits.

- Maintenance and Troubleshooting: Educate operators on basic maintenance tasks and troubleshooting procedures.

- Glass Handling Techniques: Train operators on the safe and proper handling of different types of glass.

- Equipment Care: Emphasize the importance of regular cleaning, inspection, and reporting any issues promptly.

9. Explain the role of automation in modern Glass Unloading Equipment?

Automation plays a significant role in modern Glass Unloading Equipment, enhancing efficiency and safety:

- Automated Loading and Unloading: Equipment can be equipped with automated systems for loading and unloading glass, reducing manual labor.

- Sensors and Cameras: Sensors and cameras monitor the equipment’s operation, detecting any abnormalities or potential hazards.

- Programmable Logic Controllers (PLCs): PLCs control the equipment’s logic and decision-making, ensuring smooth and efficient operation.

- Data Logging: Automated systems can log data on equipment performance, maintenance history, and glass handling operations for analysis.

- Remote Monitoring: Some systems allow for remote monitoring and control of the equipment, enabling real-time troubleshooting and support.

10. Discuss the environmental impact of Glass Unloading Equipment and sustainable practices?

Glass Unloading Equipment can have an environmental impact, and sustainable practices are essential:

- Energy Efficiency: Choosing energy-efficient equipment can reduce energy consumption and carbon footprint.

- Material Recycling: Recycling glass scraps and packaging materials can minimize waste and promote sustainability.

- Waste Reduction: Implementing waste reduction programs, such as glass recycling and proper disposal of hazardous materials, can help protect the environment.

- Noise Reduction: Selecting equipment with low noise levels can minimize noise pollution and create a more comfortable working environment.

- Sustainable Procurement: Considering the environmental impact of equipment during procurement can promote responsible sourcing.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Glass Unloading Equipment Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Glass Unloading Equipment Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Glass Unloading Equipment Tenders are responsible for the safe and efficient unloading of glass from delivery vehicles. Their main duties include:

1. Unloading glass

Manually or using equipment, they unload glass from delivery vehicles.

- Ensure that all safety regulations are followed while unloading glass

- Inspect glass for any damage or defects before unloading

- Use proper equipment to safely remove glass from delivery vehicles

2. Storage of Glass

They ensure that the glass is stored properly and safely.

- Following proper storage procedures to prevent damage to glass

- Keeping storage areas clean and organized

- Maintaining an inventory of glass in storage

3. Maintenance of Equipment

They perform basic maintenance on the glass unloading equipment.

- Performing regular inspections of glass unloading equipment

- Cleaning and lubricating equipment as needed

- Reporting any maintenance issues to the appropriate personnel

4. Safety

They follow all safety regulations and procedures.

- Wearing appropriate safety gear

- Following all safety procedures while unloading and storing glass

- Reporting any unsafe conditions to the appropriate personnel

Interview Tips

Preparing for a job interview can be nerve-wracking, but following a few simple tips can help you ace your interview and land your dream job.

1. Research the Company

Take some time to research the company you’re interviewing with. This will help you understand their culture, values, and what they’re looking for in a Glass Unloading Equipment Tender.

- Visit the company’s website

- Read about the company in the news

- Talk to people in your network who work for the company

2. Practice Your Answers

Once you’ve done your research, take some time to practice your answers to common interview questions. This will help you feel more confident and prepared during the interview.

- Think about your strengths and weaknesses

- Prepare answers to questions about your experience and qualifications

- Be prepared to talk about why you’re interested in the job

3. Dress Professionally

First impressions matter, so make sure you dress professionally for your interview. This means wearing clean, pressed clothes and shoes. You should also avoid wearing strong perfumes or colognes.

- Dress in a way that is appropriate for the company culture

- Make sure your clothes are clean and pressed

- Avoid wearing clothes that are too revealing or too casual

4. Be Yourself

The most important thing is to be yourself during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not.

- Be honest and authentic

- Let your personality shine through

- Show the interviewer that you’re passionate about the job

Next Step:

Now that you’re armed with the knowledge of Glass Unloading Equipment Tender interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Glass Unloading Equipment Tender positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini