Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Globe Mounter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

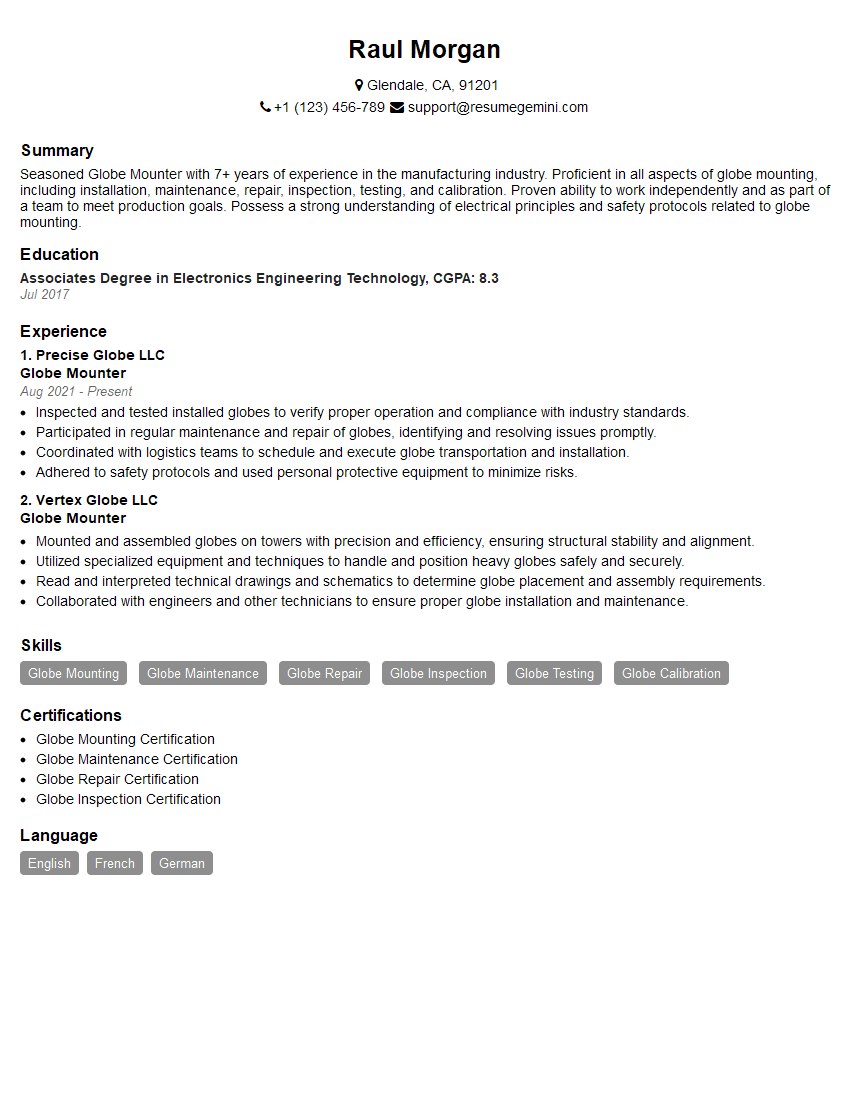

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Globe Mounter

1. What are the critical machine parameters that you monitor while operating a Globe Mounting machine?

As a Globe Mounter operator, I closely monitor the following critical machine parameters:

- Paste height: Ensuring the solder paste is applied to the correct height to prevent bridging or opens.

- Placement accuracy: Verifying the components are placed accurately within the specified tolerances.

- Component orientation: Checking that the components are oriented correctly on the board.

- Vision system: Inspecting the board for any defects or misalignments.

- Pick-and-place head: Monitoring the pick-and-place head for any errors or malfunctions.

2. How do you troubleshoot common Globe Mounting machine issues?

Identifying the issue

- Examine error codes and messages displayed on the machine interface.

- Check for loose connections, damaged cables, or faulty components.

- Inspect the components and assembly for any visible defects or misalignments.

Resolution

- Clear error codes and reset the machine if necessary.

- Tighten loose connections, replace damaged cables, or repair faulty components.

- Realign misaligned components or replace defective ones.

- Calibrate the machine if needed.

3. Describe your experience with solder paste inspection techniques?

To ensure the integrity of solder joints, I employ various solder paste inspection techniques:

- Visual inspection: Examining the solder paste under a microscope to check for proper application, consistency, and defects.

- Automated optical inspection (AOI): Utilizing specialized equipment to detect defects in solder paste, such as voids, shorts, or insufficient paste volume.

- X-ray inspection: Using X-ray technology to inspect hidden or internal solder joints for proper connections.

- Electrical testing: Performing electrical tests on the assembled board to identify any issues related to solder joint quality.

4. How do you maintain and calibrate a Globe Mounting machine?

Maintenance

- Regularly clean the machine to remove contaminants.

- Inspect and replace worn or damaged parts.

- Lubricate moving components to ensure smooth operation.

Calibration

- Use a calibration fixture or substrate to set the placement accuracy.

- Adjust the vision system for optimal image capture.

- Calibrate the pick-and-place head to ensure proper component placement.

- Verify sensor readings and adjust accordingly to maintain precise machine operation.

5. Describe your experience with Globe Mounting machine optimization?

To maximize efficiency and productivity, I have implemented several Globe Mounting machine optimization strategies:

- Cycle time reduction: Analyzing the machine cycle and identifying areas for improvement, such as optimizing component feeding or reducing pick-and-place time.

- Yield improvement: Analyzing production data to identify common defects and implementing measures to reduce them, such as improving solder paste application or component alignment.

- Setup time minimization: Streamlining the setup process by creating standardized procedures, utilizing quick-change tooling, and optimizing feeder loading.

6. How do you ensure the safety of yourself and others while operating a Globe Mounting machine?

I prioritize safety in the workplace by adhering to the following measures:

- Wearing appropriate personal protective equipment (PPE), such as safety glasses, gloves, and anti-static garments.

- Following lockout/tagout procedures before performing any maintenance or repairs.

- Keeping the work area clean and free from hazards.

- Being aware of potential pinch points and moving machinery.

- Reporting any safety concerns or incidents promptly.

7. What are the quality standards and procedures you follow while operating a Globe Mounting machine?

To ensure the production of high-quality products, I strictly adhere to the following quality standards and procedures:

- ISO 9001:2015: Complying with the requirements of the International Organization for Standardization (ISO) 9001:2015 standard for quality management systems.

- IPC-A-610: Following the IPC-A-610 acceptability criteria for electronic assemblies, ensuring the proper assembly of printed circuit boards.

- Customer specifications: Meeting specific customer requirements and product specifications, such as component placement accuracy, solder joint quality, and functional testing.

- Statistical process control (SPC): Using SPC techniques to monitor and control the machine’s performance, identifying trends and implementing corrective actions.

8. Describe your experience with preventive maintenance and downtime reduction strategies for Globe Mounting machines.

To minimize downtime and ensure the smooth operation of Globe Mounting machines, I implement the following preventive maintenance and downtime reduction strategies:

- Regular maintenance: Performing scheduled maintenance tasks, such as cleaning, lubrication, and component replacement, to prevent failures.

- Predictive maintenance: Monitoring machine parameters and data to identify potential issues before they occur, allowing for proactive maintenance.

- Root cause analysis: Investigating the underlying causes of machine breakdowns and implementing corrective measures to prevent recurrence.

- Spare parts inventory: Maintaining an adequate inventory of critical spare parts to minimize downtime in case of unexpected failures.

- Training: Ensuring operators are properly trained to operate and maintain the machines efficiently.

9. How do you handle production emergencies and ensure the timely delivery of orders?

In the event of production emergencies, I respond promptly and efficiently to minimize delays and ensure timely order delivery:

- Prioritizing tasks: Identifying critical tasks and prioritizing them based on urgency and impact on production.

- Communicating with stakeholders: Informing management, customers, and suppliers about the situation and providing updates on progress.

- Mobilizing resources: Utilizing available resources, such as additional personnel, equipment, or materials, to expedite production.

- Implementing contingency plans: Activating pre-defined contingency plans to mitigate the impact of emergencies and maintain production.

- Continuously monitoring: Monitoring the situation closely and making adjustments as needed to ensure the timely completion of orders.

10. How do you stay updated with the latest Globe Mounting machine technologies and best practices?

To stay abreast of the latest Globe Mounting machine technologies and best practices, I actively engage in the following activities:

- Attending conferences and workshops: Participating in industry events to learn about new technologies, emerging trends, and best practices.

- Reading technical literature: Studying technical manuals, white papers, and articles related to Globe Mounting machines.

- Networking with industry professionals: Connecting with peers, attending industry meetups, and exchanging knowledge and experiences.

- Participating in training programs: Enrolling in training programs offered by machine manufacturers or industry organizations to enhance my skills and knowledge.

- Research and development: Conducting research and experimenting with different techniques and approaches to improve machine performance and efficiency.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Globe Mounter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Globe Mounter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Globe Mounters are responsible for efficiently and accurately assembling electronic components onto printed circuit boards (PCBs). Their primary focus is to ensure that the assembled PCBs meet the required specifications and quality standards. Key job responsibilities typically include:

1. Component Placement

Accurately aligning and placing electronic components onto PCBs according to engineering drawings and assembly instructions.

- Properly handling delicate components to avoid damage.

- Using specialized tools and equipment to ensure precise placement.

2. Soldering

Soldering components onto PCBs using appropriate techniques and materials.

- Creating secure electrical connections between components.

- Inspecting and testing soldered joints to ensure proper conductivity.

3. Inspection and Quality Control

Thoroughly inspecting assembled PCBs for defects and errors.

- Verifying component placement and soldering quality.

- Identifying and correcting any assembly issues.

4. Equipment Operation and Maintenance

Operating and maintaining specialized equipment used in the assembly process.

- Calibrating and adjusting equipment to ensure accurate component placement and soldering.

- Performing routine maintenance and troubleshooting.

Interview Tips

Preparing adequately for a Globe Mounter interview can significantly increase your chances of success. Here are some valuable tips and hacks to help you ace the interview:

1. Highlight Your Technical Expertise

Thoroughly review the job description and identify the specific technical skills and experience required for the role. Showcase your proficiency in component placement, soldering techniques, and inspection methods.

- Quantify your accomplishments and provide specific examples of your work. For instance, you could mention the number of PCBs you assembled per hour or highlight your ability to identify and resolve assembly defects.

- Demonstrate your understanding of different types of electronic components and their functions.

2. Emphasize Your Attention to Detail

Accuracy is paramount in globe mounting. Highlight your meticulous nature and strong attention to detail.

- Explain how you ensure precise component placement and proper soldering techniques.

- Provide examples of how you have identified and corrected assembly errors in the past.

3. Showcase Your Problem-Solving Skills

Globe Mounters often encounter assembly challenges. Demonstrate your ability to troubleshoot and solve problems effectively.

- Share an example of a time when you identified and resolved an equipment issue that impacted assembly productivity.

- Discuss your approach to diagnosing and rectifying assembly defects.

4. Prepare for Common Interview Questions

Research common interview questions and prepare thoughtful answers that showcase your skills and experience. Some typical questions include:

- Tell me about your experience in globe mounting.

- How do you maintain accuracy and quality in your work?

- What are some of the challenges you have faced in globe mounting and how did you overcome them?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Globe Mounter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!