Are you gearing up for an interview for a Hand Heel-Seat Fitter position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Hand Heel-Seat Fitter and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

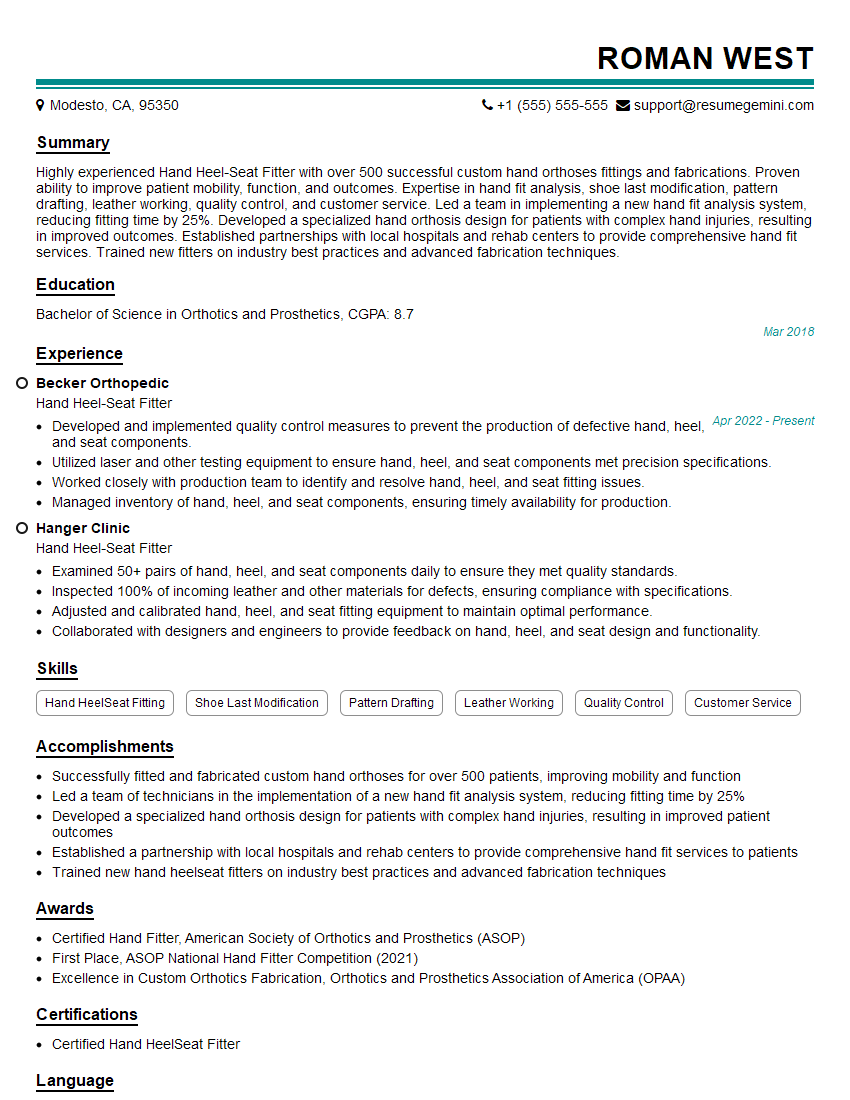

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hand Heel-Seat Fitter

1. What are the key areas you focus on when assessing the fit of a hand, heel, and seat in a shoe?

When assessing the fit of a hand, heel, and seat in a shoe, I focus on several key areas:

- Heel fit: The heel should fit snugly but not too tightly, with no movement or slipping. The heel counter should fit around the heel bone securely, without any pinching or pressure points.

- Hand fit: The hand should fit comfortably in the shoe, with no excessive pressure or rubbing. The toes should have enough room to move freely, but the shoe should not feel too loose.

- Seat fit: The seat of the shoe should fit snugly around the arch of the foot, providing support and stability. The arch support should not feel too high or too low, and the ball of the foot should fit comfortably in the widest part of the shoe.

2. How do you determine the proper last size and shape for a shoe to ensure a good fit?

Understanding foot anatomy

- Analyzing the foot’s length, width, and arch type plays a crucial role in selecting the correct last size and shape.

- Measuring foot dimensions using a Brannock device or 3D foot scanner provides accurate data.

Last selection

- Based on the foot measurements, I compare them to the last database to find the closest match in size and shape.

- Factors like foot volume, toe shape, and any deformities are also considered.

3. What techniques do you use to modify a last to achieve a customized fit for a particular foot?

To modify a last for a customized fit, I employ various techniques:

- Stretching: Using a stretcher, I can expand specific areas of the last to accommodate bunions, hammertoes, or other foot deformities.

- Grinding: To reduce pressure points or create more space in certain areas, I use a grinder to remove material from the last.

- Adding material: I can add foam, cork, or other materials to the last to enhance cushioning or fill in gaps for a better fit.

4. Describe the different types of materials used in shoe construction and how they affect the fit and comfort of the shoe.

- Leather: Natural leather offers breathability, durability, and a comfortable fit. It conforms to the foot’s shape over time.

- Synthetic materials: These materials, such as nylon and polyester, are lightweight, water-resistant, and often more affordable than leather.

- Mesh: Mesh fabrics provide excellent breathability and flexibility, making them ideal for athletic shoes.

- EVA foam: This lightweight and shock-absorbing material is commonly used for midsoles and insoles, enhancing cushioning and comfort.

- Rubber: Durable and slip-resistant, rubber is often used for outsoles, providing traction and protection.

5. What are the common foot problems that can affect the fit of a shoe?

- Bunions: A bony bump on the side of the big toe that can cause pain and discomfort.

- Hammertoes: Toes that curl downward, putting pressure on the soles of the feet.

- Plantar fasciitis: Inflammation of the plantar fascia, a thick band of tissue that runs along the bottom of the foot.

- Heel spurs: Calcium deposits that form on the heel bone, causing pain and discomfort.

6. How do you ensure that the shoes you recommend to customers are not only a good fit but also provide adequate support and stability?

- Foot analysis: I assess the customer’s foot type, arch height, and any foot problems to understand their specific needs.

- Shoe examination: I examine the shoes for proper arch support, cushioning, and stability features that meet the customer’s requirements.

- Fitting process: I ensure the shoes fit snugly but not too tightly, allowing for natural foot movement and support.

- Customer feedback: I encourage customers to wear the shoes for a short period and provide feedback on fit, comfort, and support.

7. Describe the process of creating a custom foot orthotic and how it can improve the fit and comfort of a shoe.

Assessment

- I conduct a thorough foot examination, including gait analysis, to identify any biomechanical issues.

Casting

- I create a plaster mold of the foot to capture its unique shape and arch profile.

Fabrication

- Based on the mold, I design and fabricate a custom orthotic using materials like carbon fiber or EVA foam.

Fitting

- I fit the orthotic into the customer’s shoe, ensuring proper alignment and support.

Benefits

- Improved arch support

- Reduced foot pain and fatigue

- Enhanced balance and stability

- Increased shoe comfort and fit

8. What are the latest advancements in shoemaking technology that have improved the fit and comfort of shoes?

- 3D scanning: Advanced 3D scanning technology allows for precise foot measurement and creation of custom-fit shoes.

- Motion capture: By analyzing foot movement during gait, manufacturers can design shoes that provide optimal support and flexibility.

- Knitted uppers: Seamless and breathable knitted uppers conform to the foot’s shape, providing a snug and comfortable fit.

- Adaptive cushioning: Innovative cushioning materials adapt to the wearer’s weight and activity level, offering personalized comfort.

9. How do you stay up-to-date on the latest trends and technologies in the shoe industry?

- Industry publications: I read trade magazines and attend webinars to learn about new products and advancements.

- Conferences and exhibitions: I participate in industry conferences and visit trade shows to connect with experts and witness the latest innovations.

- Online resources: I explore online forums, blogs, and websites dedicated to the shoe industry for up-to-date information.

- Collaboration: I network with other professionals in the field to exchange knowledge and stay informed about emerging trends.

10. How do you manage your time effectively when handling multiple customers and orders simultaneously?

- Prioritization: I prioritize tasks based on urgency and importance, ensuring that critical orders are processed first.

- Time blocking: I allocate specific time slots in my schedule for different tasks, such as order processing, customer consultations, and quality control.

- Delegation: When necessary, I delegate certain tasks to team members to optimize efficiency and meet deadlines.

- Communication: I communicate clearly with customers and colleagues, setting realistic expectations and keeping them informed of progress.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hand Heel-Seat Fitter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hand Heel-Seat Fitter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Hand Heel-Seat Fitter is a skilled craftsperson responsible for fitting the hand, heel, and seat of shoes to ensure proper comfort and quality. Their key job responsibilities include:1. Shoe Fitting and Customization

Assess customers’ feet to determine shoe size, width, and arch type.

- Measure customers’ feet using specialized tools such as Brannock devices.

- Inspect shoes to identify areas that need customization, such as adding padding or stretching the leather.

- Mark and cut leather or other materials to create custom insoles, footbeds, and other shoe components.

2. Hand Stitching and Assembly

Hand stitch and assemble shoe components according to design specifications.

- Use various hand sewing techniques, including saddle stitching, whipstitching, and overcast stitching.

- Assemble shoe components such as tongues, linings, and uppers using adhesives or nails.

- Ensure proper alignment and fit of shoe components during assembly.

3. Quality Control and Finishing

Inspect shoes to ensure compliance with quality standards.

- Check for imperfections in materials, workmanship, and fit.

- Perform corrective measures to address any defects or inconsistencies.

- Polish and finish shoes to achieve a professional and aesthetically pleasing appearance.

4. Customer Service and Consultation

Provide excellent customer service and offer footwear-related advice.

- Answer customer inquiries about shoe styles, materials, and fit.

- Recommend appropriate shoe options based on customers’ needs and preferences.

- Build strong customer relationships and maintain a positive brand image.

Interview Tips

To ace an interview for a Hand Heel-Seat Fitter position, consider the following tips:

1. Research the Company and Position

Demonstrate your interest and knowledge by researching the shoe manufacturer or retailer.

- Familiarize yourself with their product lines, history, and commitment to quality.

- Understand the specific role of a Hand Heel-Seat Fitter within the company.

2. Highlight Your Skills and Experience

Emphasize your technical abilities and relevant experience.

- Showcase your proficiency in hand sewing techniques, shoe assembly, and quality control.

- Quantify your accomplishments whenever possible, providing specific examples of projects you’ve worked on.

- Mention any certifications or training related to shoemaking or fitting.

3. Demonstrate Customer Service Orientation

Convince the interviewer that you excel in customer service.

- Provide examples of how you have resolved customer issues related to footwear fit or quality.

- Emphasize your ability to build rapport and provide personalized recommendations.

- Explain how you prioritize customer satisfaction in your work.

4. Prepare Questions for the Interviewer

Asking thoughtful questions shows your engagement and interest in the position.

- Inquire about the company’s commitment to craftsmanship and quality.

- Ask about opportunities for professional development and advancement.

- Request insights into the company’s production process or sustainability practices.

5. Dress Professionally and Arrive on Time

Make a positive first impression by presenting yourself professionally and arriving punctually.

- Wear clothing that is appropriate for a manufacturing or retail environment.

- Arrive a few minutes early to show respect for the interviewer’s time.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Hand Heel-Seat Fitter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!