Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Hand Laminator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

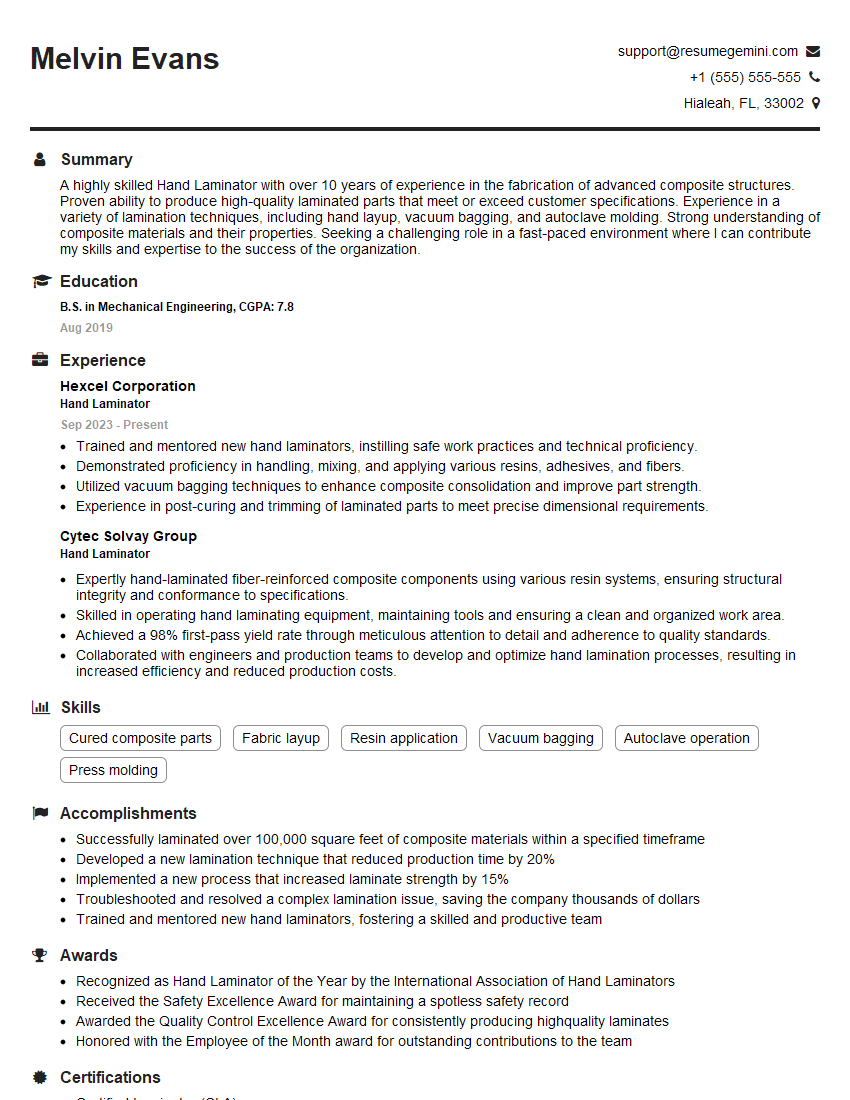

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hand Laminator

1. Explain the process of hand laminating?

Hand laminating involves applying layers of resin-impregnated fiberglass or carbon fiber to a mold or substrate. The process typically includes the following steps:

- Preparing the mold or substrate by cleaning and applying a release agent.

- Cutting and laying down the first layer of fiberglass or carbon fiber.

- Applying a layer of resin to the fiberglass or carbon fiber, using a brush or roller.

- Repeating steps 2 and 3 until the desired number of layers is achieved.

- Curing the laminate at the appropriate temperature and pressure.

- Trimming and finishing the laminate as needed.

2. What are the different types of resins used in hand laminating?

- Polyester resin

- Vinyl ester resin

- Epoxy resin

- Phenolic resin

- Urethane resin

3. What are the different types of fibers used in hand laminating?

- Fiberglass

- Carbon fiber

- Aramid fiber

- Polyethylene terephthalate (PET) fiber

- Polypropylene fiber

4. What are the key factors that affect the quality of a hand-laminated product?

- The quality of the materials used

- The skill of the laminator

- The curing conditions

- The post-curing treatment

5. What are some of the common defects that can occur in hand-laminated products?

- Air bubbles

- Resin-rich areas

- Fiber-rich areas

- Delamination

- Cracking

6. How can you prevent defects from occurring in hand-laminated products?

- Use high-quality materials

- Properly prepare the mold or substrate

- Use the correct mixing ratio for the resin and hardener

- Apply the resin evenly and thoroughly

- Cure the laminate at the appropriate temperature and pressure

- Inspect the laminate regularly for defects

7. What are some of the applications for hand-laminated products?

- Boat hulls

- Automotive parts

- Wind turbine blades

- Medical devices

- Sporting goods

8. What are the advantages of hand laminating over other composite manufacturing processes?

- It is a relatively simple and inexpensive process.

- It allows for the production of complex shapes.

- It is versatile and can be used with a variety of materials.

- It produces high-quality laminates with excellent mechanical properties.

9. What are the disadvantages of hand laminating over other composite manufacturing processes?

- It is a labor-intensive process.

- It can be difficult to achieve consistent quality.

- It is not suitable for high-volume production.

10. What are the latest trends in hand laminating?

- The use of new materials, such as carbon fiber and aramid fiber.

- The development of new curing techniques, such as vacuum bagging and autoclave curing.

- The use of computer-aided design and manufacturing (CAD/CAM) to improve the quality and efficiency of the process.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hand Laminator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hand Laminator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Hand Laminators are responsible for applying resin and fiberglass to molds to create various products. They are often required to operate and maintain a variety of equipment.

1. Laminate Products

Their primary responsibility is to lay down layers of fiberglass mat and resin onto molds to create products. They must ensure that the materials are applied evenly and smoothly to achieve a high-quality finish.

- Prepare molds and surfaces for lamination

- Apply resin and fiberglass to molds according to specifications

- Trim and finish laminated products

2. Operate and Maintain Equipment

Hand Laminators are also responsible for setting up and operating laminating equipment, which includes resin mixers, application guns, and curing ovens. They must also maintain and clean the equipment to ensure optimal performance.

- Set up and operate laminating equipment

- Maintain and clean laminating equipment

- Troubleshoot and repair laminating equipment

3. Maintain a Safe Work Environment

Hand Laminators must follow safety protocols to protect themselves and others. They must wear appropriate safety gear and handle hazardous materials with care.

- Wear appropriate safety gear

- Handle hazardous materials with care

- Maintain a clean and organized work area

4. Adhere to Quality Standards

Hand Laminators must adhere to strict quality standards to ensure that the products they produce meet the customer’s specifications. They must inspect their work regularly and make adjustments as needed.

- Inspect laminated products for defects

- Make adjustments to the laminating process as needed

- Maintain records of completed work

Interview Tips

Preparing for an interview is essential for a successful performance. Here are some tips to help you ace your Hand Laminator interview:

1. Research the Company and Position

Take the time to research the company you’re applying to and the specific Hand Laminator position. This will give you a good understanding of the company’s culture, values, and what they’re looking for in a candidate.

- Visit the company’s website and social media pages

- Read articles and news about the company

- Talk to people in your network who work for the company

2. Practice Your Answers to Common Interview Questions

There are some common interview questions that you’re likely to be asked, such as “Tell me about yourself” or “Why are you interested in this position?” Practice answering these questions in a clear and concise way, and tailor your answers to the specific job you’re applying for.

- Use the STAR method to answer behavioral questions

- Highlight your skills and experience that are relevant to the job

- Be enthusiastic and confident in your answers

3. Prepare Questions to Ask the Interviewer

Asking thoughtful questions at the end of the interview shows that you’re interested in the position and the company. It also gives you an opportunity to learn more about the company and the role. Some good questions to ask include:

- What are the biggest challenges facing the company right now?

- What are the opportunities for growth and development in this role?

- What is the company culture like?

4. Dress Professionally and Arrive on Time

First impressions matter, so make sure you dress professionally and arrive on time for your interview. This shows that you’re respectful of the interviewer’s time and that you’re serious about the position.

- Wear clean, pressed clothes

- Arrive on time for your interview

- Be polite and respectful to the interviewer

5. Follow Up After the Interview

After the interview, it’s important to follow up with the interviewer. This shows that you’re still interested in the position and that you’re eager to learn more. You can send a thank-you note or an email to reiterate your interest and thank the interviewer for their time.

- Send a thank-you note or email within 24 hours of the interview

- Reiterate your interest in the position

- Thank the interviewer for their time

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Hand Laminator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!