Are you gearing up for a career in Hot Pipe Gauger? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Hot Pipe Gauger and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

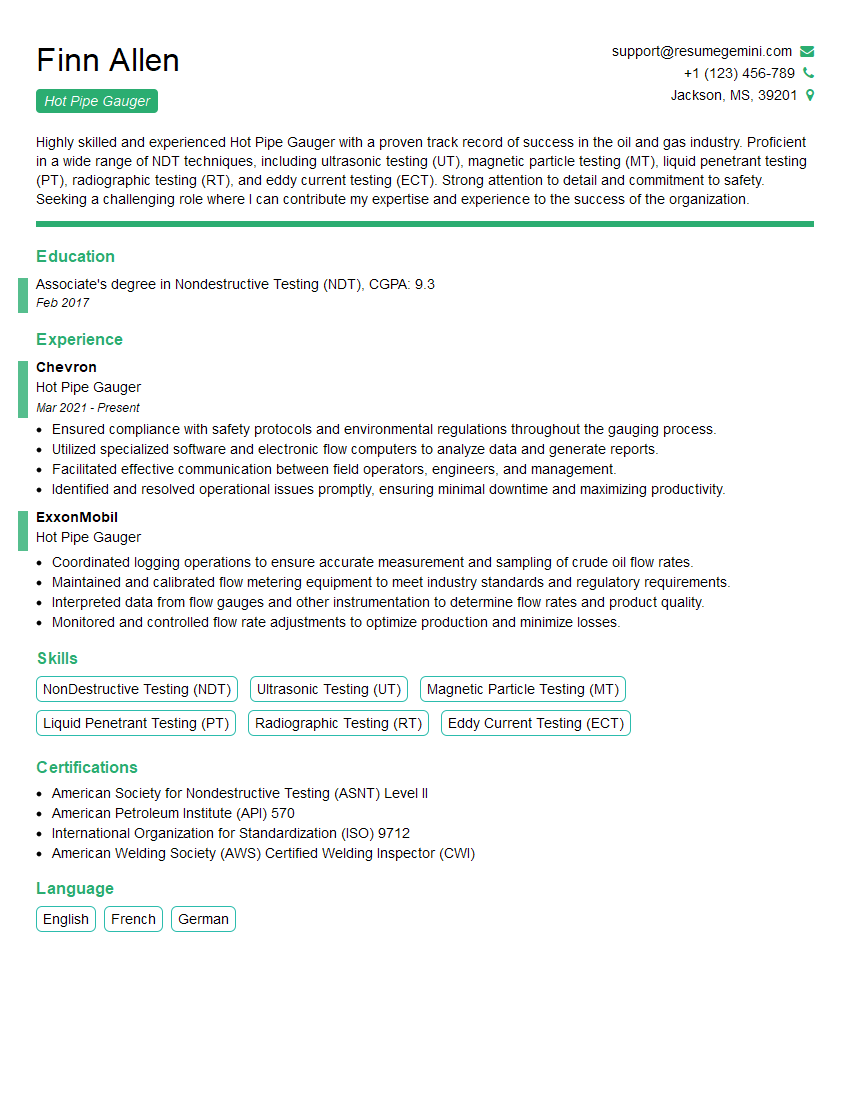

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hot Pipe Gauger

1. Explain the process of gauging a hot pipe?

- Calibrating the measuring device to ensure accuracy.

- Cleaning the hot pipe surface to remove any debris or rust.

- Erecting the measuring device at the designated location on the hot pipe.

- Taking the initial reading to establish the reference point.

- Checking the temperature of the hot pipe using a pyrometer or other appropriate device.

- Entering the temperature reading into the measuring device to adjust for expansion.

- Adjusting the measuring device as necessary to obtain a precise reading.

- Recording the measurements and any deviations from the specified tolerance limits.

2. What are the different types of hot pipe gauging equipment?

- Ultrasonic gauging: Uses ultrasonic waves to measure pipe wall thickness through non-destructive testing.

- Eddy current gauging: Employs electromagnetic fields to detect variations in pipe wall thickness and identify corrosion or defects.

- Magnetic flux leakage gauging: Utilizes magnetic fields to detect and measure surface and subsurface flaws in ferromagnetic pipes.

- Laser gauging: Employs lasers to scan the pipe surface and measure its profile, thickness, and any irregularities.

- Optical gauging: Uses light sources and sensors to measure pipe dimensions, detect defects, and determine surface roughness.

3. What are the factors that can affect the accuracy of hot pipe gauging?

- Pipe temperature: Extreme temperatures can alter the pipe’s dimensions and affect the accuracy of measurements.

- Pipe surface condition: Rust, scale, or debris on the pipe surface can interfere with the gauging process.

- Equipment calibration: Regularly calibrating the gauging equipment is crucial to ensure its accuracy and reliability.

- Operator skill and experience: Proper training and experience are necessary for operators to obtain precise and consistent readings.

- Environmental conditions: Factors such as wind, rain, or extreme temperatures can impact the accuracy of the gauging process.

4. Describe the safety precautions that must be taken when gauging hot pipes?

- Personal protective equipment (PPE): Wearing appropriate PPE, including heat-resistant clothing, gloves, and safety glasses, is essential.

- Hazard assessment: Conduct a thorough risk assessment to identify potential hazards and implement appropriate control measures.

- Pipe isolation: Ensure that the pipe is isolated and cooled down sufficiently before commencing gauging operations.

- Proper handling of equipment: Handle gauging equipment with care to avoid damage and ensure its accuracy.

- Training and supervision: Provide comprehensive training to operators and ensure proper supervision to minimize risks.

5. How do you interpret the results of hot pipe gauging and determine if there are any deviations from the specified tolerance limits?

- Compare measurements to specified tolerance limits: Determine if the measured pipe wall thickness or other parameters meet the established standards.

- Identify deviations and analyze causes: If deviations are detected, investigate the underlying causes, such as corrosion, thinning, or manufacturing defects.

- Recommend appropriate actions: Based on the analysis, suggest corrective actions, such as repairs, replacements, or further inspection.

- Document findings and recommendations: Create detailed reports to record the gauging results, deviations, and recommended actions.

- Communicate findings effectively: Clearly communicate the gauging results and recommendations to relevant stakeholders, including engineers, maintenance personnel, and management.

6. Describe your experience in using different hot pipe gauging techniques.

Ultrasonic gauging

- Explain the principle of ultrasonic gauging and how it is used to measure pipe wall thickness.

- Describe the equipment setup, calibration, and measurement procedures involved in ultrasonic gauging.

- Discuss the advantages and limitations of ultrasonic gauging for hot pipe inspection.

Eddy current gauging

- Explain the principle of eddy current gauging and how it is used to detect defects in hot pipes.

- Describe the equipment setup, calibration, and measurement procedures involved in eddy current gauging.

- Discuss the advantages and limitations of eddy current gauging for hot pipe inspection.

7. What are the common defects that can be detected using hot pipe gauging?

- Corrosion: Thinning of the pipe wall due to chemical or electrochemical reactions.

- Erosion: Wear and thinning of the pipe wall caused by abrasive fluids or particles.

- Cracking: Fractures or breaks in the pipe wall due to stress, fatigue, or defects.

- Pitting: Localized corrosion that creates small cavities in the pipe wall.

- Manufacturing defects: Imperfections in the pipe wall introduced during the manufacturing process, such as laminations or inclusions.

8. How do you handle and calibrate hot pipe gauging equipment?

- Equipment handling: Describe proper handling techniques to prevent damage to the equipment, such as using insulated gloves and avoiding excessive force.

- Calibration procedures: Explain the calibration process, including the use of reference standards, frequency checks, and adjustments to ensure accurate measurements.

- Calibration frequency: Discuss the importance of regular calibration and the factors that determine the frequency, such as equipment usage and environmental conditions.

9. Describe your experience in managing a team of hot pipe gaugers.

- Explain your role and responsibilities in leading a team of hot pipe gaugers.

- Discuss the strategies you use to manage team performance, motivate individuals, and ensure quality control.

- Describe your approach to communication, conflict resolution, and team development.

10. How do you keep up with the latest advancements and best practices in hot pipe gauging?

- Industry conferences and workshops: Attend industry events to stay informed about new technologies and best practices.

- Technical publications: Read technical journals, white papers, and industry reports to expand knowledge and stay updated on advancements.

- Training and certification: Pursue additional training and certifications to enhance skills and demonstrate proficiency in the field.

- Collaboration with peers: Engage with other hot pipe gauging professionals to share knowledge, discuss challenges, and learn from different perspectives.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hot Pipe Gauger.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hot Pipe Gauger‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Hot Pipe Gaugers play a vital role in the oil and gas industry, ensuring the accurate measurement of hot pipes during the production process. Their key responsibilities include:

1. Pipe Measurement and Inspection

Utilizing specialized gauging equipment, they meticulously measure the external dimensions, such as diameter and roundness, of hot pipes. This ensures compliance with industry standards and specifications.

- Operate laser gauging systems to measure pipe dimensions.

- Inspect pipes for defects, such as cracks, dents, or corrosion.

2. Data Collection and Recording

They diligently record all measurement data, including dimensions, temperature, and any observed defects. This data is crucial for quality control and pipe traceability.

- Document measurement results using electronic or paper-based systems.

- Maintain accurate records of all gauging operations.

3. Equipment Maintenance and Calibration

To ensure precise measurements, Hot Pipe Gaugers are responsible for the maintenance and calibration of gauging equipment. They perform routine checks, troubleshoot issues, and coordinate repairs as needed.

- Perform regular maintenance and calibration of laser gauging systems.

- Troubleshoot and resolve equipment malfunctions.

4. Safety Compliance

Working in an industrial environment requires a strong commitment to safety. Hot Pipe Gaugers adhere to all safety regulations, wear appropriate protective gear, and follow safety protocols to minimize risks.

- Comply with all safety procedures and regulations.

- Wear appropriate personal protective equipment (PPE).

Interview Tips

To enhance your chances of success in an interview for a Hot Pipe Gauger position, consider the following preparation tips:

1. Research the Company and Industry

Demonstrate your interest in the company and the industry by thoroughly researching their website, LinkedIn profile, and recent news articles. This knowledge will enable you to connect your skills and experience to their specific needs.

- Read the company’s website and social media pages.

- Review the company’s recent financial reports and press releases.

2. Highlight Relevant Skills and Experience

Tailor your resume and cover letter to emphasize the skills and experience most relevant to the job description. Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Highlight your proficiency in operating laser gauging systems.

- Provide examples of how you have improved measurement accuracy or efficiency.

3. Prepare for Common Interview Questions

Anticipate common interview questions related to your skills, experience, and knowledge of the industry. Practice your answers to articulate your qualifications and enthusiasm for the role.

- Tell me about your experience in measuring hot pipes.

- How do you ensure the accuracy of your measurements?

4. Ask Thoughtful Questions

Prepare thoughtful questions to ask the interviewer, demonstrating your genuine interest and engagement. This also provides an opportunity to clarify any details about the role or company.

- What are the key challenges facing the industry right now?

- How does the company prioritize safety in its operations?

5. Follow Up and Express Gratitude

After the interview, promptly send a thank-you note to the interviewer, reiterating your interest in the position and expressing your appreciation for their time. This final touch can leave a lasting positive impression.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Hot Pipe Gauger interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.