Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Insulating Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

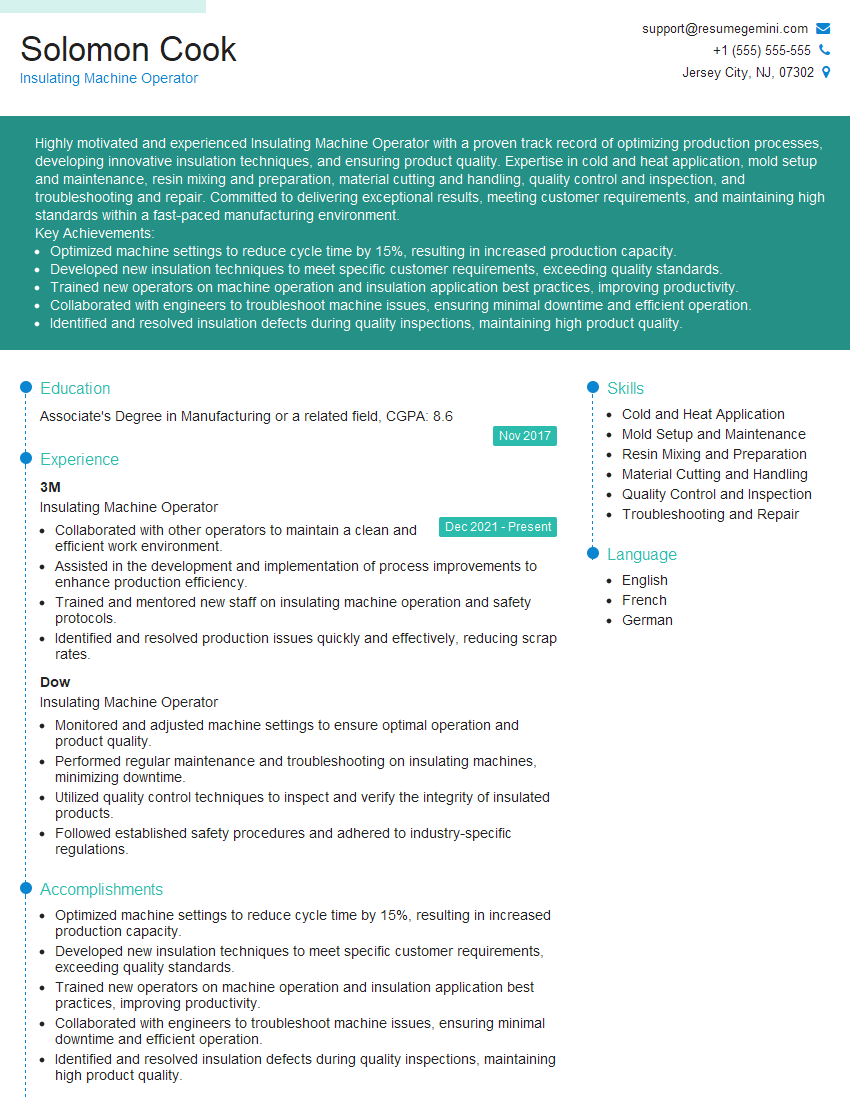

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Insulating Machine Operator

1. What are the different types of insulating materials?

There are many different types of insulating materials, each with its own unique properties. Some of the most common types of insulating materials include:

- Fiberglass

- Cellulose

- Polystyrene

- Polyurethane

- Rock wool

2. What are the benefits of using insulation?

Reduced energy costs

- Insulation can help to reduce energy costs by keeping heat in during the winter and out during the summer.

Increased comfort

- Insulation can help to make a home more comfortable by reducing drafts and noise.

Improved air quality

- Insulation can help to improve air quality by trapping dust and allergens.

Increased home value

- Insulation can help to increase the value of a home by making it more energy-efficient and comfortable.

3. What are the different types of insulating machine operators?

There are two main types of insulating machine operators: hand-feed operators and machine-feed operators.

- Hand-feed operators manually feed the material into the insulating machine.

- Machine-feed operators operate the machine that automatically feeds the material into the insulating machine.

4. What are the qualifications for becoming an insulating machine operator?

The qualifications for becoming an insulating machine operator vary depending on the specific job, but most employers will require at least a high school diploma or equivalent. Some employers may also require experience operating insulating machines or related equipment.

- High school diploma or equivalent

- Experience operating insulating machines or related equipment

- Knowledge of insulation materials and their properties

- Ability to read and understand blueprints and other technical drawings

- Ability to work independently and as part of a team

5. What are the responsibilities of an insulating machine operator?

The responsibilities of an insulating machine operator vary depending on the specific job, but most will be responsible for the following:

- Operating insulating machines to apply insulation to materials

- Setting up and adjusting insulating machines

- Inspecting insulated materials for defects

- Maintaining and cleaning insulating machines

6. What are the safety precautions that should be taken when operating insulating machines?

There are several safety precautions that should be taken when operating insulating machines, including:

- Wearing appropriate safety gear, such as gloves, safety glasses, and a respirator

- Keeping the work area clean and free of debris

- Being aware of the location of all electrical wires and cables

- Never operating an insulating machine that is not in good working order

7. What are the troubleshooting tips for insulating machines?

There are several troubleshooting tips for insulating machines, including:

- Checking the power supply to the machine

- Checking the air pressure to the machine

- Checking the material feed system

- Checking the insulation application system

8. What are the maintenance procedures for insulating machines?

There are several maintenance procedures for insulating machines, including:

- Cleaning the machine regularly

- Lubricating the machine regularly

- Inspecting the machine for wear and tear

- Replacing worn or damaged parts

9. What are the quality control procedures for insulating machines?

There are several quality control procedures for insulating machines, including:

- Inspecting the insulated materials for defects

- Testing the insulated materials to ensure they meet specifications

- Calibrating the insulating machine regularly

10. What is the future of insulating machine operation?

The future of insulating machine operation is bright. As the demand for energy-efficient buildings increases, the demand for insulating materials and insulating machine operators will also increase. In addition, the development of new insulating materials and insulating machines will continue to improve the efficiency and quality of insulation.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Insulating Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Insulating Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Insulating Machine Operators play a vital role in the production process by operating and maintaining insulating machines to create electrical insulation for various components and products. Their responsibilities encompass a range of tasks that contribute to the smooth functioning of the production line and the quality of the end products.

1. Machine Operation and Maintenance

Insulating Machine Operators are responsible for the proper operation and maintenance of insulating machines. They ensure that the machines are set up and calibrated correctly, and that they are running smoothly and efficiently. They also perform regular maintenance tasks, such as cleaning and lubricating the machines, to prevent breakdowns and ensure optimal performance.

2. Quality Control

Insulating Machine Operators are responsible for ensuring the quality of the insulated components and products. They inspect the finished products to ensure that they meet the required specifications and standards. They also perform quality control tests to ensure that the insulation is of the correct thickness and density, and that it meets the required electrical properties.

3. Troubleshooting

Insulating Machine Operators are also responsible for troubleshooting and resolving any problems that may arise during the production process. They use their knowledge of the machines and the insulation process to identify and fix any issues that may occur, ensuring that the production line continues to operate smoothly.

4. Process Optimization

Insulating Machine Operators may also be involved in process optimization efforts to improve the efficiency and productivity of the production line. They may work with engineers and other production staff to identify and implement improvements that can reduce waste, increase production rates, and improve the overall quality of the insulated products.

Interview Tips

Preparing for an interview for an Insulating Machine Operator position requires a thorough understanding of the job responsibilities and the key skills and qualifications that employers are looking for. Here are some tips to help you ace your interview and demonstrate your suitability for the role:

1. Research the Company and Position

Take the time to learn about the company you’re applying to, their products or services, and the specific role of an Insulating Machine Operator within their organization. This will help you understand the company’s culture, their mission, and the specific requirements of the position.

2. Highlight Your Skills and Experience

During the interview, emphasize your skills and experience that are relevant to the job responsibilities of an Insulating Machine Operator. Focus on your ability to operate and maintain insulating machines, your quality control experience, and your troubleshooting skills. Provide specific examples of your work that demonstrate your proficiency in these areas.

3. Demonstrate Your Knowledge of the Industry

Insulating Machine Operators should have a basic understanding of the electrical insulation industry and the different types of insulation materials and processes used in the manufacturing of electrical components and products. Show the interviewer that you are familiar with the industry standards and best practices, and that you are up-to-date on the latest technologies and advancements in the field.

4. Be Prepared to Discuss Safety

Safety is paramount in any manufacturing environment, including the operation of insulating machines. Be prepared to discuss your understanding of safety procedures and your commitment to maintaining a safe work environment. Highlight any safety training or certifications you have, and demonstrate your ability to follow safety protocols and identify potential hazards.

5. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position. It also gives you an opportunity to clarify any details about the role or the company. Prepare a few questions that demonstrate your enthusiasm for the job and your desire to learn more about the organization.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Insulating Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!