Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Last Ironer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

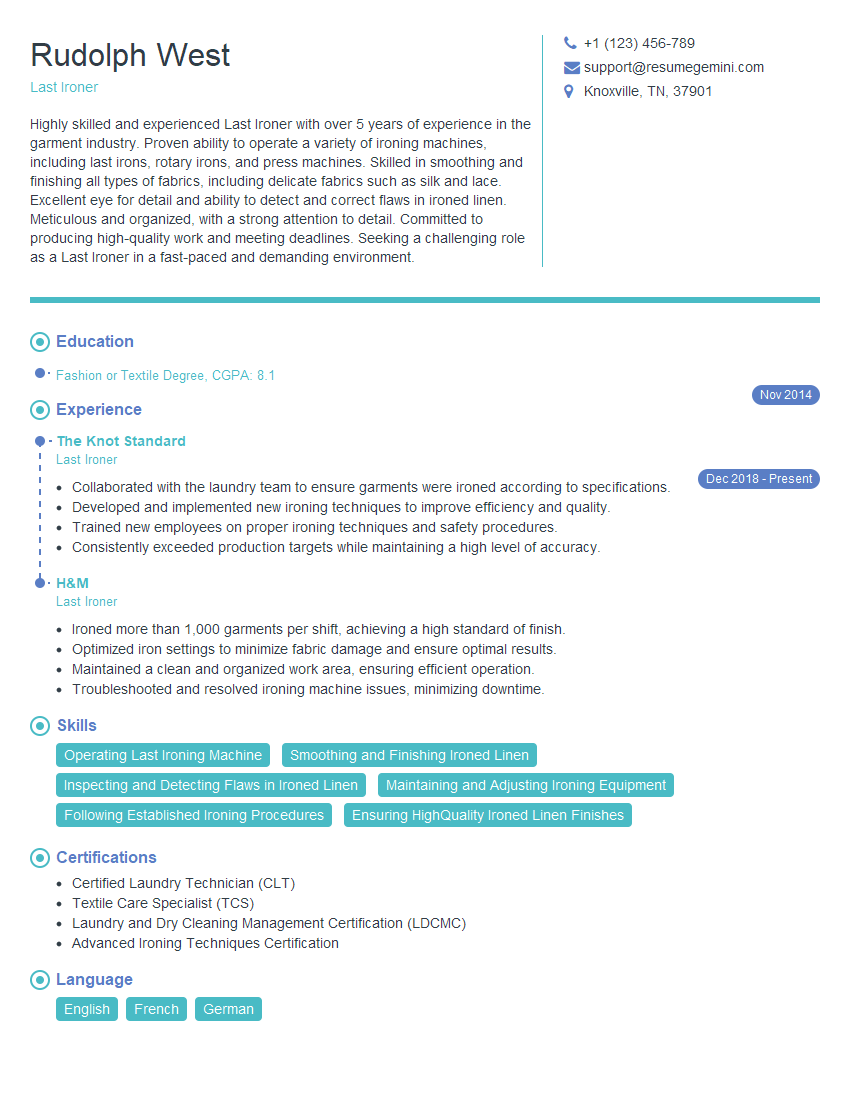

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Last Ironer

1. Explain the key components of an industrial ironing machine and their functions.

- Rollers: Responsible for applying heat and pressure to the fabric, ironing it flat.

- Conveyor belt: Transports the fabric through the ironing process.

- Heat source: Provides the heat required for ironing, typically using steam or electricity.

- Speed and tension control: Regulates the speed and tension of the fabric as it moves through the machine.

- Safety sensors: Monitor the machine’s operation and prevent accidents.

2. Describe the different types of fabrics that can be ironed using an industrial ironing machine and their specific considerations.

Cotton and Linen

- High heat, moderate moisture

- Avoid overpressing to prevent scorching

Silk and Wool

- Low heat, high moisture

- Use a pressing cloth to protect from direct heat

Synthetics

- Low heat, no moisture

- Test fabrics first to determine appropriate temperature

3. How do you adjust the heat and speed of an industrial ironing machine to achieve optimal ironing results?

- Heat: Adjust based on the fabric type (see question 2).

- Speed: Set according to the thickness and moisture content of the fabric.

- Use a moisture control system: This adds humidity to the ironing process, improving the results for certain fabrics.

4. What are the common causes of fabric damage during industrial ironing, and how do you prevent them?

- Overheating: Use correct heat settings and avoid ironing for extended periods.

- Excess moisture: Avoid overdampening fabrics, especially when ironing at high temperatures.

- Incorrect roller pressure: Adjust pressure according to fabric weight and thickness.

- Improper tension: Ensure the fabric is taut but not excessively stretched.

- Debris on rollers: Regularly clean rollers to remove any buildup that could damage fabrics.

5. Describe the importance of regular maintenance for industrial ironing machines.

- Extends machine lifespan: Prevents wear and tear, reducing costly repairs.

- Ensures optimal performance: Keeps the machine operating efficiently, delivering consistent ironing results.

- Reduces downtime: Prevents unexpected breakdowns, minimizing production disruptions.

- Improves safety: Regular inspections identify potential hazards and prevent accidents.

6. Explain how to troubleshoot and resolve common issues with industrial ironing machines.

- Roller malfunction: Check for debris, adjust pressure, or replace if necessary.

- Conveyor belt problems: Inspect for tears or blockages, repair or replace as needed.

- Temperature issues: Calibrate thermostat or replace heating elements.

- Moisture control system failure: Check water supply, inspect nozzles, and replace faulty components.

- Electrical faults: Refer to the manufacturer’s manual for specific troubleshooting steps.

7. Describe the steps involved in setting up and operating an industrial ironing machine.

- Installation: Position the machine according to manufacturer’s instructions, connect utilities.

- Initial setup: Set heat and speed controls, adjust conveyor belt tension.

- Fabric loading: Feed fabrics onto the conveyor belt, ensuring proper orientation.

- Operation: Monitor ironing process, adjust settings as needed to achieve desired results.

- End of production: Unload ironed fabrics, clean the machine, and prepare it for storage.

8. How do you ensure the quality of ironed fabrics and meet customer specifications?

- Inspect fabrics before ironing: Check for defects or stains.

- Establish clear ironing parameters: Determine heat, speed, and moisture settings for each fabric type.

- Monitor ironing process: Observe the fabric as it passes through the machine, making adjustments as needed.

- Use quality control tools: Measure shrinkage, inspect for wrinkles, and ensure proper color retention.

- Follow customer specifications: Adhere to specified ironing methods, packaging requirements, and delivery deadlines.

9. How do you prioritize tasks and manage workload in a busy industrial ironing environment?

- Establish a workflow: Determine the most efficient sequence for ironing different fabrics.

- Prioritize orders: Handle urgent orders first and allocate resources accordingly.

- Delegate tasks: Assign specific responsibilities to team members to expedite the process.

- Monitor progress: Track the status of orders and make adjustments to the workflow as needed.

- Communicate effectively: Stay informed of production schedules and any changes to customer requirements.

10. How do you stay up-to-date with advancements in industrial ironing technology and best practices?

- Attend industry events and workshops: Learn about new machines, techniques, and industry trends.

- Read trade publications and online resources: Stay informed about industry news and best practices.

- Consult with equipment manufacturers: Seek advice and technical support from industry experts.

- Participate in continuing education programs: Enhance skills and knowledge through formal training.

- Network with other professionals: Exchange ideas and learn from colleagues in the field.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Last Ironer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Last Ironer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Last Ironer is responsible for the final pressing and finishing of laundered items in commercial laundry operations. They ensure that items are ironed to the desired quality and appearance, meeting the standards of the establishment.

1. Ironing and Pressing

The primary responsibility of a Last Ironer is to iron and press various items such as table linens, napkins, bed sheets, pillowcases, and towels. They use specialized ironing equipment, including flatwork ironers, rotary ironers, and hand irons, to remove wrinkles and creases from the fabric.

- Operate and maintain ironing equipment, ensuring optimal performance and efficiency.

- Adjust ironing settings (temperature, speed, pressure) based on the type of fabric and desired finish.

2. Quality Control

Last Ironers are responsible for inspecting and ensuring the quality of the ironed items. They check for any remaining wrinkles, creases, or imperfections and make necessary adjustments to achieve the desired appearance.

- Inspect ironed items for defects, such as burns, stains, or tears.

- Re-iron or touch up items that do not meet quality standards.

3. Material Handling

Last Ironers are involved in the handling and movement of large quantities of laundered items. They load and unload ironing equipment, ensuring proper feeding and positioning of items for efficient ironing.

- Load and unload flatwork ironers and rotary ironers.

- Handle and move heavy bundles of linens and other items.

4. Team Collaboration

Last Ironers work as part of a team in the laundry department. They collaborate with other laundry staff, such as washers, extractors, and folders, to ensure a smooth and efficient workflow.

- Communicate with other team members to coordinate ironing schedules and prioritize tasks.

- Assist with other tasks in the laundry department as needed.

Interview Tips

Preparing for a Last Ironer interview requires understanding the key responsibilities of the role and presenting yourself as a suitable candidate. Here are some tips to help you ace the interview:

1. Research the Company and Position

Research the laundry establishment and the specific position you are applying for. This will give you a good understanding of the company’s values, operations, and expectations for the role.

- Visit the company’s website to learn about their services, clientele, and industry reputation.

- Review the job description carefully, paying attention to the key responsibilities and qualifications required.

2. Highlight Relevant Experience and Skills

Emphasize your experience in ironing and pressing techniques. If you have worked in a commercial laundry setting, describe the types of items you handled and the equipment you used.

- Showcase your attention to detail and ability to achieve high-quality results.

- Mention any training or certifications you have in ironing and pressing.

3. Demonstrate Teamwork and Communication Skills

Explain how you work effectively in a team environment and communicate with colleagues.

- Describe a situation where you collaborated with others to achieve a common goal.

- Emphasize your ability to follow instructions and communicate any issues or concerns promptly.

4. Prepare for Common Interview Questions

Research common interview questions related to the Last Ironer role and prepare your answers accordingly.

- Why are you interested in working as a Last Ironer?

- What experience do you have in ironing and pressing different types of fabrics?

- How do you ensure the quality of your work?

- Can you describe a time when you had to handle a difficult customer or situation?

- What are your strengths and weaknesses as a Last Ironer?

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Last Ironer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Last Ironer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.