Are you gearing up for an interview for a Lead Oxide Mill Tender position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Lead Oxide Mill Tender and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

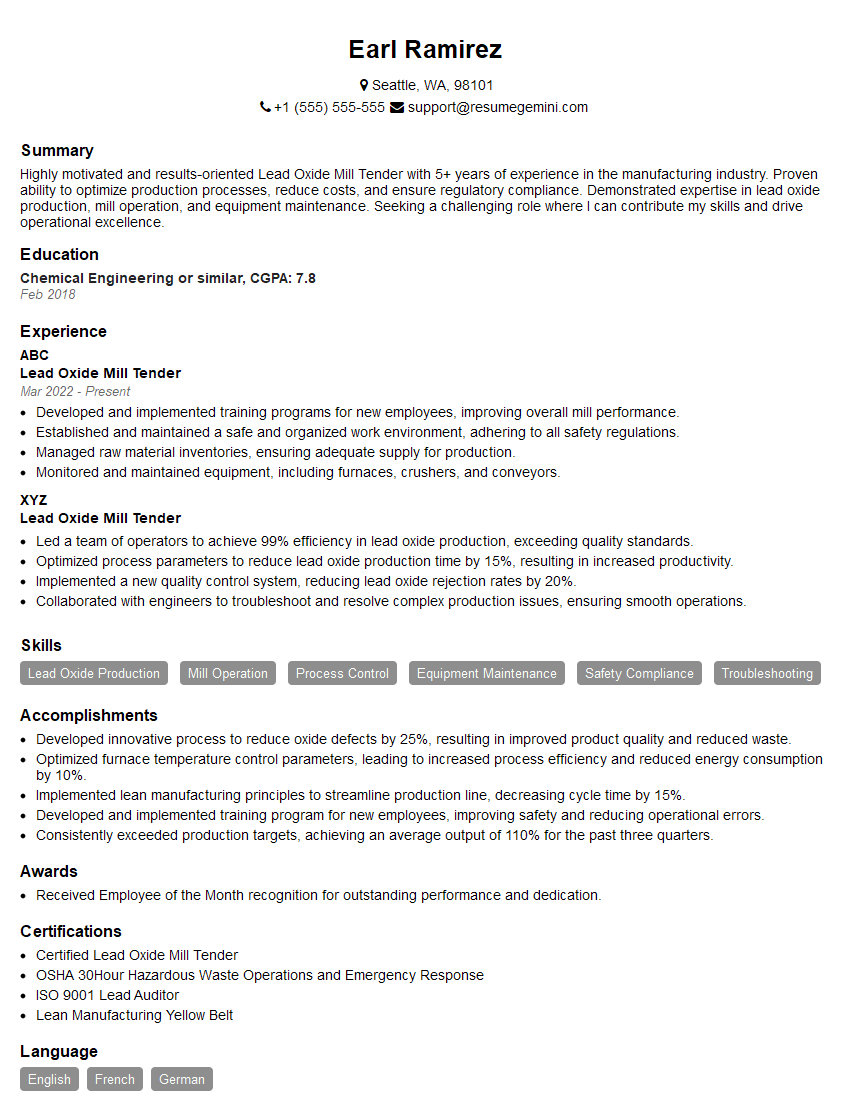

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lead Oxide Mill Tender

1. What are the key responsibilities of a Lead Oxide Mill Tender?

As a Lead Oxide Mill Tender, my primary responsibilities include:

- Supervising and coordinating the operations of the lead oxide mill

- Ensuring the production of lead oxide of the required quality and quantity

- Monitoring the mill equipment and processes to ensure efficient operation

- Troubleshooting and resolving any issues that may arise during production

- Maintaining a safe and clean work environment

2. Describe the process of manufacturing lead oxide in a mill.

Sintering Process

- Lead concentrates are smelted to produce lead bullion.

- The lead bullion is then oxidized in a furnace to form lead oxide.

Refining Process

- The lead oxide is then refined to remove impurities.

- This can be done through a variety of methods, such as electrolysis, precipitation, or solvent extraction.

Milling Process

- The refined lead oxide is then milled to reduce its particle size.

- This is typically done using a ball mill or a jet mill.

3. How do you ensure the quality of the lead oxide produced?

I ensure the quality of the lead oxide produced by:

- Regularly testing the lead oxide to ensure that it meets the required specifications

- Monitoring the mill equipment and processes to ensure that they are operating efficiently

- Implementing quality control measures throughout the production process

4. What are the common troubleshooting issues in lead oxide production and how do you resolve them?

Common troubleshooting issues in lead oxide production include:

- Low lead oxide yield: This can be caused by a number of factors, such as insufficient oxygen supply, low temperature, or incorrect raw material composition. To resolve this issue, I would check the oxygen supply, increase the temperature, or adjust the raw material composition.

- High lead oxide impurity levels: This can be caused by the presence of impurities in the raw materials or by contamination during the production process. To resolve this issue, I would identify the source of the impurities and take steps to remove them.

- Equipment failure: This can be caused by a number of factors, such as wear and tear, improper maintenance, or operator error. To resolve this issue, I would identify the cause of the failure and take steps to repair or replace the equipment.

5. What safety precautions are necessary when working in a lead oxide mill?

When working in a lead oxide mill, it is important to take the following safety precautions:

- Wear appropriate personal protective equipment (PPE), such as a respirator, gloves, and eye protection

- Avoid inhaling lead oxide dust

- Wash hands thoroughly after handling lead oxide

- Follow all safety procedures and protocols

6. What is the role of automation in lead oxide production?

Automation plays a significant role in lead oxide production by:

- Improving efficiency and productivity

- Reducing costs

- Improving safety

- Ensuring consistency in production

7. What are the emerging trends in lead oxide production?

Emerging trends in lead oxide production include:

- The use of more sustainable and environmentally friendly processes

- The development of new and innovative technologies to improve efficiency and productivity

- The increasing use of automation and digitalization

8. How do you stay up-to-date on the latest advancements in lead oxide production?

I stay up-to-date on the latest advancements in lead oxide production by:

- Reading industry publications

- Attending conferences and trade shows

- Networking with other professionals in the field

- Conducting research and development

9. What are your career goals and how do you see this role fitting into them?

My career goal is to become a Plant Manager in the lead oxide industry. I believe that this role will provide me with the skills and experience necessary to achieve my goal. It will allow me to develop my leadership, management, and technical skills. I am confident that I can make a significant contribution to your company and help you achieve your business objectives.

10. Do you have any questions for me?

I would like to know more about the company’s commitment to safety. What specific measures are in place to protect employees from exposure to lead oxide?

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lead Oxide Mill Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lead Oxide Mill Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Lead Oxide Mill Tenders are responsible for the safe and efficient operation of lead oxide mills. They work under the supervision of a mill foreman or supervisor and perform a variety of tasks, including:

1. Operating and maintaining lead oxide mills

Lead Oxide Mill Tenders are responsible for operating and maintaining lead oxide mills. This involves:

- Starting and stopping the mill

- Monitoring the mill’s operation

- Making adjustments to the mill’s settings

- Performing routine maintenance on the mill

2.Producing lead oxide

Lead Oxide Mill Tenders are responsible for producing lead oxide. This involves:

- Adding raw materials to the mill

- Controlling the temperature and pressure of the mill

- Monitoring the quality of the lead oxide

- Packaging and storing the lead oxide

3.Ensuring safety and compliance

Lead Oxide Mill Tenders are responsible for ensuring the safety and compliance of their work area. This involves:

- Following all safety procedures

- Using personal protective equipment

- Maintaining a clean and organized work area

- Complying with all environmental regulations

4.Other duties

In addition to the above, Lead Oxide Mill Tenders may also be responsible for:

- Training new employees

- Assisting with research and development projects

- Troubleshooting problems with the mill

- Performing other tasks as assigned

Interview Tips

Preparing for an interview for a Lead Oxide Mill Tender position can be daunting, but following a few simple tips can help you increase your chances of success.

1. Research the company and the position

Before your interview, take some time to research the company you’re applying with and the position you’re interested in. This will help you understand the company’s culture, goals, and expectations for the role.

2. Prepare your answers to common interview questions

There are a number of common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Prepare your answers to these questions in advance so that you can deliver them confidently and succinctly.

3. Practice your answers

Once you’ve prepared your answers to common interview questions, practice delivering them out loud. This will help you become more comfortable with the material and make you less likely to stumble over your words during the actual interview.

4. Dress professionally

First impressions matter, so make sure to dress professionally for your interview. This means wearing a suit or dress pants and a button-down shirt or blouse. You should also make sure your clothes are clean and pressed.

5. Be on time

Punctuality is important, so make sure to arrive for your interview on time. If you’re running late, call the interviewer to let them know.

6. Be yourself

The most important thing is to be yourself during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not.

By following these tips, you can increase your chances of success in your interview for a Lead Oxide Mill Tender position. Good luck!

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Lead Oxide Mill Tender, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Lead Oxide Mill Tender positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.