Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Lining Inserter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

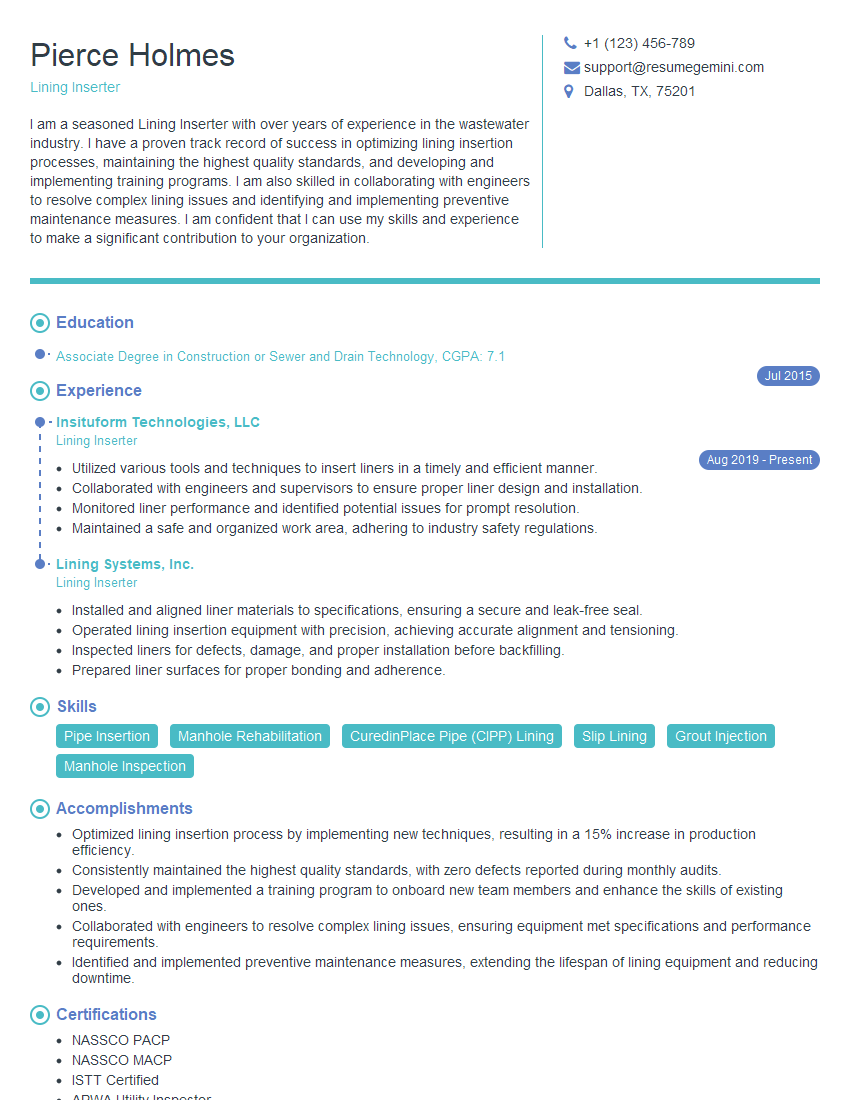

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lining Inserter

1. What are the different types of lining materials used in manufacturing?

- Polypropylene

- Polyethylene

- Polytetrafluoroethylene (PTFE)

- Polyvinyl chloride (PVC)

- Natural rubber

2. Explain the process of inserting a lining into a pipe or fitting?

Prepare the lining and pipe

- Clean the pipe or fitting to remove any debris or contaminants.

- Inspect the lining for any defects or damage.

- Measure and cut the lining to the desired length.

Insert the lining

- Apply a thin layer of adhesive to the inside of the pipe or fitting.

- Insert the lining into the pipe or fitting, starting at one end and working your way to the other.

- Smooth out the lining and remove any wrinkles or air bubbles.

Cure the lining

- Allow the adhesive to cure for the specified time.

- Once the adhesive is cured, the lining is ready to use.

3. What are the safety precautions that should be taken when working with lining materials?

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a respirator.

- Work in a well-ventilated area.

- Avoid contact with skin and eyes.

- Follow the manufacturer’s instructions for handling and storage.

- Dispose of used materials properly.

4. What are the common problems that can occur when inserting a lining?

- The lining is not properly prepared or installed.

- The adhesive is not properly cured.

- The lining is damaged during installation.

- The pipe or fitting is not properly prepared.

- The environment is not suitable for lining installation.

5. What are the different methods of lining inspection?

- Visual inspection

- Ultrasonic testing

- Radiographic testing

- Eddy current testing

- Magnetic particle testing

6. What are the different types of lining repair techniques?

- Patching

- Relining

- Replacement

- Rehabilitation

- Renovation

7. What are the different applications of lining materials?

- Pipelines

- Tanks

- Valves

- Fittings

- Pumps

8. What are the advantages of using lining materials?

- Increased corrosion resistance

- Reduced friction

- Improved flow characteristics

- Increased wear resistance

- Lower maintenance costs

9. What are the disadvantages of using lining materials?

- High initial cost

- Limited lifespan

- Can be difficult to repair

- Can be damaged by improper installation or use

- May not be suitable for all applications

10. How do you stay up to date on the latest lining materials and techniques?

- Attend industry conferences and trade shows.

- Read industry publications and journals.

- Participate in online forums and discussion groups.

- Network with other lining professionals.

- Take continuing education courses.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lining Inserter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lining Inserter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Lining Inserter is responsible for the proper installation of linings in pipes and tanks. They work with a variety of materials, including rubber, plastic, and metal. Lining Inserters must be able to follow instructions carefully and work independently.

1. Inspecting pipes and tanks

Before installing a lining, the Lining Inserter must inspect the pipe or tank to make sure that it is clean and free of any debris. They also need to check for any damage that could affect the installation of the lining.

2. Preparing the lining

Once the pipe or tank has been inspected, the Lining Inserter will prepare the lining for installation. This may involve cutting the lining to the correct size and shape, and then applying a sealant to the edges.

3. Installing the lining

The Lining Inserter will then install the lining into the pipe or tank. This may involve using a variety of tools, such as a roller or a brush. Once the lining has been installed, the Lining Inserter will check to make sure that it is properly sealed and that there are no leaks.

4. Testing the lining

After the lining has been installed, the Lining Inserter will test it to make sure that it is functioning properly. This may involve filling the pipe or tank with water or air and then checking for any leaks.

Interview Tips

To ace an interview for a Lining Inserter position, it is important to be prepared and to practice your answers to common interview questions. Here are a few tips to help you prepare for your interview:

1. Research the company and the position

Before your interview, it is important to do your research on the company and the position you are applying for. This will help you to better understand the company’s culture and the specific requirements of the job.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is important to practice your answers to these questions so that you can deliver them confidently and clearly.

3. Be prepared to talk about your experience and skills

The interviewer will want to know about your experience and skills that make you a good fit for the position. Be prepared to talk about your past work experience, your education, and any relevant skills that you have.

4. Be enthusiastic and positive

The interviewer will be able to tell if you are excited about the position and the company. Be enthusiastic and positive throughout the interview, and make sure to express your interest in the job.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Lining Inserter interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.