Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Lumber Straightener position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

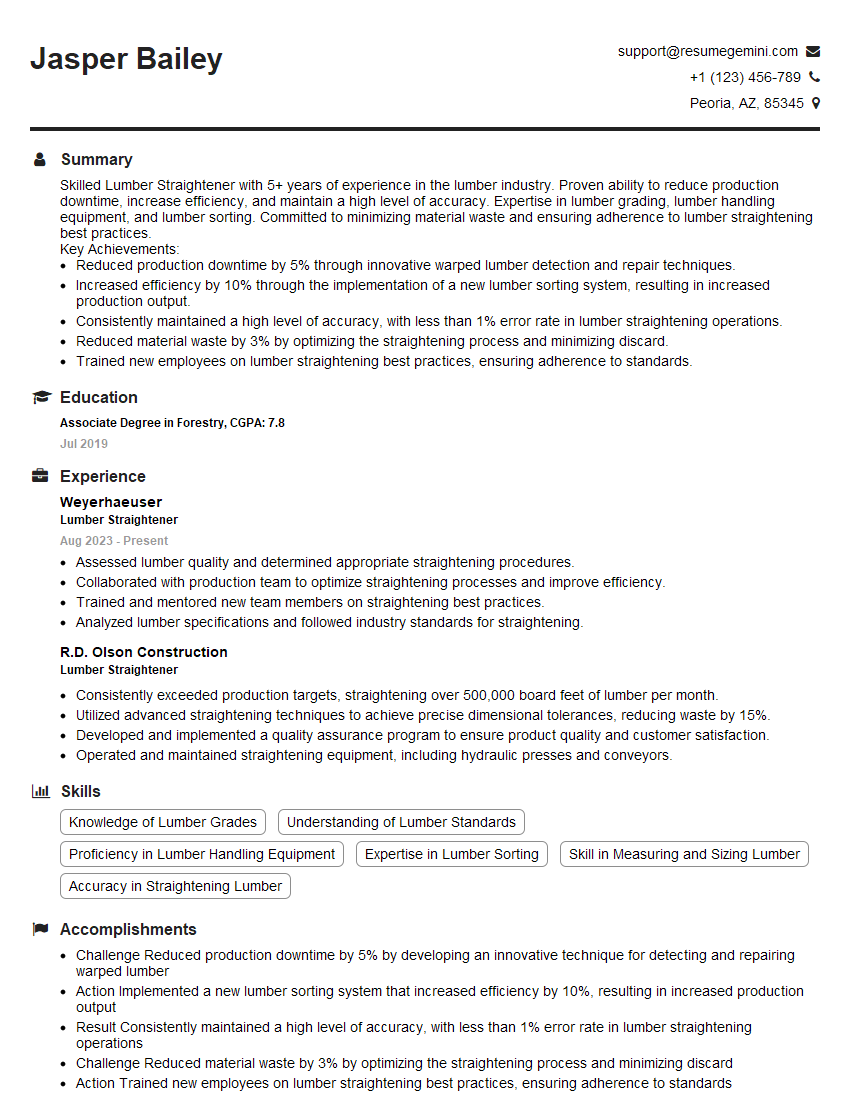

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lumber Straightener

1. Can you explain the process of lumber straightening?

The process of lumber straightening involves removing the natural curvature or warping from lumber. It is crucial to ensure the stability and strength of the lumber for various construction projects.

- Lumber is first selected and assessed for its curvature and moisture content.

- The lumber is then placed in a lumber straightener, a machine that applies controlled pressure and heat to gradually straighten the lumber.

- The machine uses heated rollers or platens to apply pressure and heat, while the lumber is held securely in place.

- The straightening process gradually adjusts the lumber’s moisture content and fiber alignment, reducing the curvature.

- After straightening, the lumber is cooled and conditioned to stabilize its moisture content and prevent further warping.

2. What are the different types of lumber straighteners available?

Hydraulic straighteners

- Utilize hydraulic pressure to apply force and heat to the lumber.

- Provide precise control over the straightening process and can handle various lumber sizes.

Pneumatic straighteners

- Use compressed air to generate pressure and heat for straightening lumber.

- Suitable for smaller lumber sizes and offer portability.

Mechanical straighteners

- Employ mechanical force, such as gears and rollers, to straighten lumber.

- Robust and can handle heavy loads, but may require more manual adjustments.

3. How do you determine the appropriate settings for a lumber straightener based on the lumber’s characteristics?

To determine the appropriate settings, I consider the lumber’s species, thickness, width, moisture content, and the desired level of straightening.

- Species: Different wood species have varying densities and fiber structures, which influence the straightening process.

- Thickness and width: Thicker and wider lumber requires higher pressure and longer straightening time.

- Moisture content: Lumber with higher moisture content is more pliable and easier to straighten.

- Desired level of straightening: The extent of curvature to be removed determines the pressure and temperature settings.

4. How do you troubleshoot and resolve common issues that may arise during lumber straightening?

Common issues include:

- Excessive cracking: May be caused by applying too much pressure or heat.

- Incomplete straightening: Can occur if the settings are not adjusted correctly or the lumber is too dry.

- Warping after straightening: May indicate uneven moisture distribution or improper conditioning after straightening.

To resolve these issues:

- Adjust pressure and temperature: Fine-tune the settings to optimize the straightening process.

- Check moisture content: Ensure the lumber is at an appropriate moisture level for straightening.

- Allow for proper conditioning: Cool and condition the lumber after straightening to prevent warping.

5. What safety precautions should be observed when operating a lumber straightener?

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and earplugs.

- Inspect the machine regularly and ensure it is in good working order.

- Keep hands and other body parts away from moving components.

- Never attempt to clear jammed lumber while the machine is running.

- Follow the manufacturer’s operating instructions and safety guidelines.

6. How do you maintain and calibrate a lumber straightener to ensure its accuracy and efficiency?

Regular maintenance and calibration are crucial for optimal performance:

- Cleaning: Regularly clean rollers, platens, and other components to remove debris and buildup.

- Lubrication: Lubricate moving parts as per manufacturer’s recommendations.

- Calibration: Use a calibration jig or ruler to verify the accuracy of the straightening process.

- Pressure gauge maintenance: Ensure pressure gauges are accurate to maintain consistent pressure.

- Electrical safety: Inspect electrical components and wiring for any damage or loose connections.

7. Can you describe the different methods used to measure the curvature of lumber?

- Straight edge: A straight edge is placed along the lumber to identify any deviations from a straight line.

- Measuring tape: A measuring tape can be used to measure the difference in height between the ends of the lumber and its center.

- Deflection gauge: A deflection gauge measures the amount of deflection when a load is applied to the lumber.

- Laser level: A laser level can project a straight line onto the lumber, highlighting any curvature.

8. What techniques can be employed to prevent lumber from warping after straightening?

- Proper conditioning: Allow the lumber to cool and stabilize its moisture content after straightening.

- Flat storage: Store the lumber flat on a level surface to prevent sagging.

- Weighting: Place weights or clamps on the lumber to prevent movement and warping.

- Cross-stacking: Stack lumber in alternating directions to distribute weight evenly and reduce warping.

9. How do you ensure that straightened lumber meets the required specifications for construction projects?

- Regular quality checks: Inspect the straightened lumber for any defects or deviations from specifications.

- Calibration of equipment: Regularly calibrate the lumber straightener to maintain accuracy.

- Adherence to industry standards: Follow established industry standards and guidelines for lumber straightening.

- Documentation: Maintain records of straightening parameters and quality checks for traceability and compliance.

10. What are some of the latest advancements in lumber straightening technology?

- Automated lumber grading systems: These systems use sensors and AI to automatically grade lumber based on its curvature and other characteristics.

- High-speed lumber straighteners: These machines can straighten lumber at faster rates, increasing productivity.

- Laser-guided straightening: Lasers are used to guide the straightening process, ensuring precision and reducing operator error.

- Environmental monitoring systems: These systems monitor temperature and humidity during the straightening process to optimize results.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lumber Straightener.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lumber Straightener‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Lumber Straighteners play a crucial role in the lumber industry, ensuring that the lumber produced is of the highest quality and meets industry standards. Their key responsibilities include:

1. Inspecting and Sorting Lumber

Lumber Straighteners meticulously inspect each piece of lumber for any defects, such as knots, cracks, warps, or bends. They grade the lumber based on its quality and sort it accordingly, ensuring that it meets the required specifications for its intended use.

2. Operating Straightening Machines

When lumber exhibits warps or bends, Lumber Straighteners operate specialized machines to correct these imperfections. They adjust the machine settings to apply the appropriate pressure and heat to straighten the lumber, ensuring it meets the desired specifications.

3. Maintaining Equipment

Lumber Straighteners are responsible for maintaining the proper functioning of the straightening machines and other equipment they use. This includes regular cleaning, lubrication, and adjustments to ensure optimal performance and prevent breakdowns. Proper maintenance helps to minimize downtime and maintain efficiency.

4. Working as Part of a Team

Lumber Straighteners often work alongside other team members, including lumber graders and sawyers. Effective communication and collaboration are essential to ensure a smooth workflow and maintain a safe and productive work environment.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some essential interview preparation tips for Lumber Straightener candidates:

1. Research the Company and Position

Take the time to research the company you’re applying to, including their history, values, and the specific requirements of the Lumber Straightener position. Understanding the company’s culture and the role’s expectations will help you tailor your answers and demonstrate your interest.

2. Prepare Examples of Your Skills and Experience

During the interview, you will likely be asked about your experience and skills. Prepare specific examples that highlight your abilities in lumber inspection, straightening, and maintaining equipment. Quantify your accomplishments whenever possible using metrics or numbers to demonstrate your impact.

3. Practice Answering Common Interview Questions

Familiarize yourself with common interview questions and practice your answers. Anticipate questions about your experience, qualifications, teamwork skills, and why you are interested in the position. Prepare concise and well-structured answers that showcase your strengths and enthusiasm for the role.

4. Dress Professionally and Be Punctual

Your appearance and punctuality convey respect and professionalism. Dress appropriately for the interview, ensuring your attire is clean, pressed, and fits well. Arrive at the interview location on time to show your respect for the interviewer’s schedule.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Lumber Straightener interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!