Feeling lost in a sea of interview questions? Landed that dream interview for Machine Inker but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Machine Inker interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

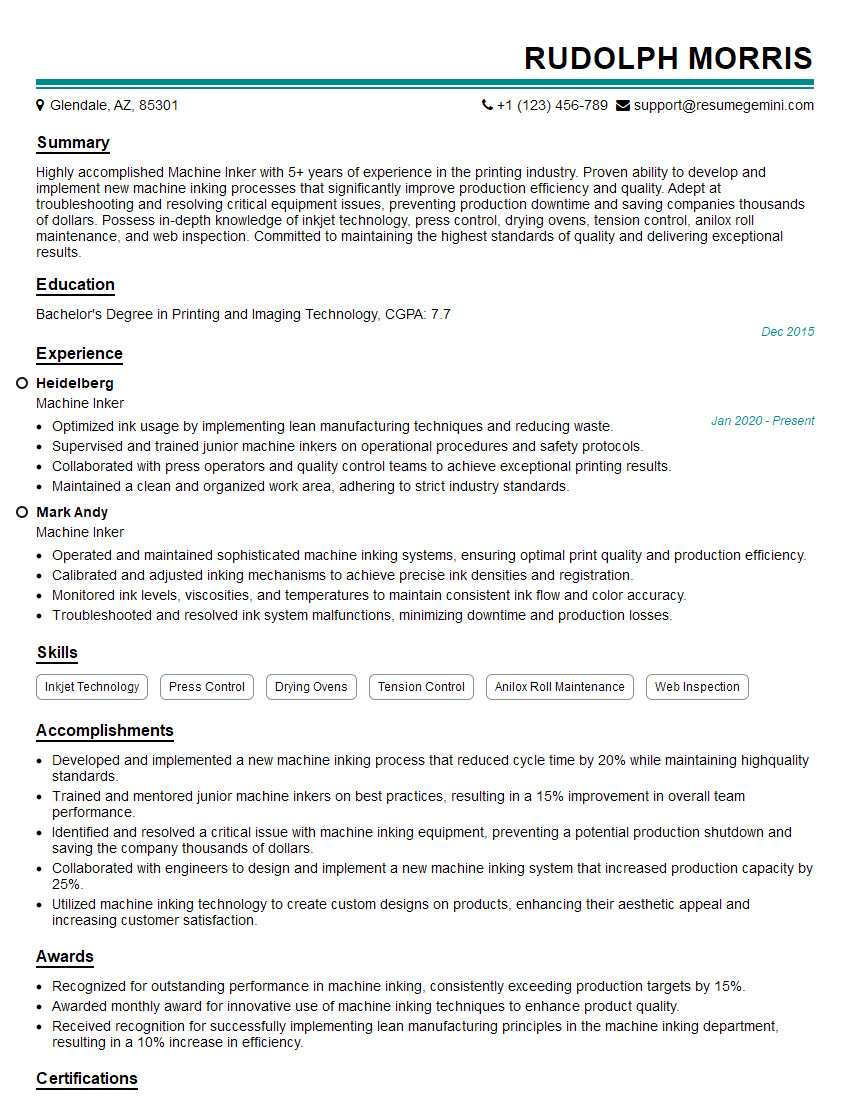

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Inker

1. What are the key responsibilities of a Machine Inker?

- Prepare and operate inking machines to apply ink to various types of materials, such as paper, foil, or plastic.

- Monitor the inking process to ensure consistent quality and adherence to specifications.

- Adjust machine settings and troubleshoot any problems that arise during the inking process.

- Clean and maintain inking equipment to ensure optimal performance.

- Follow safety protocols and maintain a clean and organized work area.

2. What are the different types of inking machines used in the industry?

- Offset printing presses: These machines use a rubber roller to transfer ink from a metal plate to paper or other materials.

- Flexographic printing presses: These machines use a flexible rubber plate to transfer ink to a variety of materials, including paper, plastic, and metal.

- Gravure printing presses: These machines use a metal cylinder with etched cells to transfer ink to paper or other materials.

- Screen printing presses: These machines use a stencil to transfer ink to fabric, paper, or other materials.

- Digital printing presses: These machines use a digital file to create an image on paper or other materials.

3. What are the different types of inks used in the industry?

- Offset inks: These inks are used in offset printing presses and are made of a combination of pigments, resins, and oils.

- Flexographic inks: These inks are used in flexographic printing presses and are made of a combination of pigments, resins, and solvents.

- Gravure inks: These inks are used in gravure printing presses and are made of a combination of pigments, resins, and solvents.

- Screen printing inks: These inks are used in screen printing presses and are made of a combination of pigments, resins, and solvents.

- Digital printing inks: These inks are used in digital printing presses and are made of a combination of pigments, resins, and polymers.

4. What are the common problems that can occur during the inking process and how to troubleshoot them?

- Poor ink transfer: This can be caused by a variety of factors, including incorrect machine settings, worn or damaged rollers, or insufficient ink supply.

- Uneven ink coverage: This can be caused by incorrect machine settings, worn or damaged rollers, or inconsistent ink viscosity.

- Ghosting: This occurs when a faint image of the printed image appears on the back of the paper. This can be caused by excessive ink application, incorrect machine settings, or worn or damaged rollers.

- Set-off: This occurs when the printed ink transfers to the back of the next sheet of paper. This can be caused by excessive ink application, incorrect machine settings, or worn or damaged rollers.

- Drying problems: This can be caused by incorrect machine settings, insufficient drying time, or the use of incompatible inks or substrates.

5. What are the safety precautions that must be followed when operating an inking machine?

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a mask.

- Keep hands and loose clothing away from moving parts.

- Do not operate the machine if it is damaged or malfunctioning.

- Follow all lockout/tagout procedures before performing any maintenance or repairs.

- Be aware of the location of emergency stop buttons and fire extinguishers.

6. What are the quality control procedures that must be followed to ensure consistent ink quality?

- Regularly monitor ink viscosity and adjust as necessary.

- Inspect ink for any signs of contamination or degradation.

- Calibrate inking equipment regularly.

- Perform test prints to verify ink quality and adherence to specifications.

- Maintain records of all quality control checks and inspections.

7. What are the maintenance and cleaning procedures that must be followed to keep an inking machine in good working condition?

- Regularly clean ink rollers, plates, and other components.

- Lubricate moving parts as per the manufacturer’s instructions.

- Inspect equipment for any signs of wear or damage.

- Perform regular maintenance checks to ensure optimal performance.

- Keep a maintenance log to track all maintenance and cleaning activities.

8. What are the key skills and experience required to be a successful Machine Inker?

- Proficient in the operation and maintenance of inking machines

- Knowledge of different types of inks and their properties

- Understanding of printing processes and quality control procedures

- Ability to troubleshoot and resolve common inking problems

- Strong attention to detail and a commitment to quality

9. What are your strengths and weaknesses as a Machine Inker?

Strengths- Proficient in the operation and maintenance of various types of inking machines

- Excellent knowledge of different types of inks and their properties

- Strong understanding of printing processes and quality control procedures

- Ability to troubleshoot and resolve common inking problems quickly and efficiently

- Excellent attention to detail and a commitment to producing high-quality work

- Limited experience with digital printing processes

- Still developing my skills in lean manufacturing and continuous improvement

10. What are your career goals and how do you see this role fitting into your long-term plans?

- My ultimate career goal is to become a Printing Production Manager.

- I believe that this role as a Machine Inker will provide me with the essential skills and experience necessary to achieve my long-term goal.

- I am eager to learn more about the entire printing process and to contribute to the production of high-quality printed materials.

- I am confident that my strong work ethic and dedication to continuous improvement will make me a valuable asset to your team.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Inker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Inker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Machine Inker is responsible for operating and maintaining the inking machine that prints designs on various materials, such as paper, fabric, and plastic. The primary duties of a Machine Inker include:

1. Machine Operation

Setting up and operating the inking machine according to the specifications provided.

- Loading and unloading the inking machine with materials and ink.

- Adjusting the machine settings, such as speed, pressure, and temperature, to ensure optimal printing quality.

2. Maintenance and Troubleshooting

Performing regular maintenance and cleaning of the inking machine to ensure its proper functioning.

- Inspecting and checking for any potential problems or malfunctioning parts.

- Troubleshooting and resolving any technical issues that may arise during the printing process.

3. Quality Control

Monitoring the printing process and ensuring the quality of the printed products.

- Inspecting the printed materials for any defects or errors.

- Making necessary adjustments to the inking machine or printing process to maintain consistent quality.

4. Health and Safety

Adhering to health and safety regulations and guidelines to ensure a safe work environment.

- Wearing appropriate protective gear, such as gloves and safety glasses.

- Handling chemicals and inks according to the prescribed safety procedures.

Interview Tips

To prepare for an interview for a Machine Inker position, it is important to have a clear understanding of the key responsibilities and the skills and experience required for the role. Here are some tips and hacks to help you ace your interview:

1. Research the Company and Position

Familiarize yourself with the company’s business, products or services, and the specific requirements of the Machine Inker position. This will demonstrate your interest in the opportunity and your dedication to the role.

- Visit the company’s website and social media pages to learn about their culture, values, and recent developments.

- Carefully read the job description to identify the essential qualifications, skills, and experience required for the position.

2. Highlight Relevant Skills and Experience

Emphasize your technical proficiency in operating and maintaining inking machines. Showcase your experience in troubleshooting and resolving printing issues. Additionally, highlight your attention to detail and commitment to quality control.

- Provide specific examples of how you have successfully operated and maintained inking machines in previous roles.

- Describe situations where you have identified and resolved printing problems, ensuring the smooth operation of the machine.

- Explain how you have implemented quality control measures to maintain the consistency and accuracy of printed products.

3. Demonstrate Safety Awareness and Compliance

Emphasize your understanding of health and safety regulations and your commitment to maintaining a safe work environment. Highlight your experience in handling chemicals and inks according to prescribed safety procedures.

- Explain your knowledge of industry-standard safety protocols for operating inking machines.

- Provide examples of how you have implemented safety measures to prevent accidents and ensure the well-being of yourself and your colleagues.

4. Prepare for Technical Questions

Expect to be asked technical questions about the operation and maintenance of inking machines. Be prepared to discuss your knowledge of different machine types, printing processes, and troubleshooting techniques.

- Review the principles of inking technology, including the different types of inks, printing methods, and machine components.

- Practice troubleshooting common printing problems, such as ink smudging, color registration errors, and paper jams.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Machine Inker role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.