Are you gearing up for a career in Machine Stamper? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Machine Stamper and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

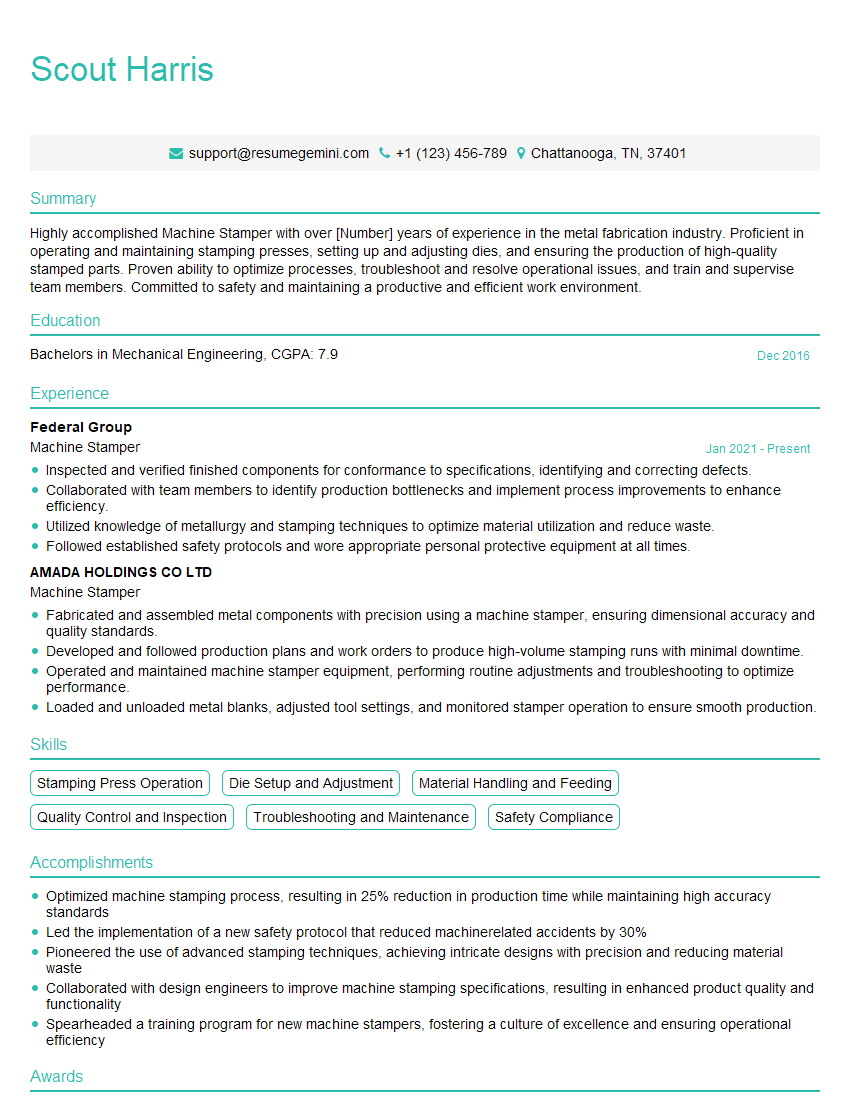

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Stamper

1. What are the different types of machine stampers and their applications?

There are a variety of machine stampers, each with its own unique applications. Some of the most common types include:

- Handheld stampers: These are the most basic type of stamper and are typically used for small-scale stamping operations. They are lightweight and portable, making them ideal for use in a variety of settings.

- Benchtop stampers: These stampers are larger than handheld stampers and are typically mounted on a bench or table. They are more powerful than handheld stampers and can be used for a wider range of stamping applications.

- Floor-mounted stampers: These stampers are the largest and most powerful type of stamper. They are typically used for large-scale stamping operations and can stamp a variety of materials, including metal, plastic, and wood.

2. What are the different types of stamping dies and how do they work?

Punch and die:

- These are the most common type of stamping die and consist of a punch and a die. The punch is shaped to create the desired stamped image, and the die is a metal block that supports the material being stamped.

Progressive dies:

- These dies are used for high-volume stamping operations and consist of a series of punches and dies that are arranged in a sequence. Each punch and die performs a specific operation, such as cutting, forming, or embossing.

Transfer dies:

- These dies are used to stamp complex shapes that cannot be stamped with a punch and die. They consist of a punch, a die, and a transfer plate. The punch is shaped to create the desired stamped image, and the die is a metal block that supports the material being stamped. The transfer plate is used to transfer the stamped image from the punch to the die.

3. What are the different types of materials that can be stamped?

A variety of materials can be stamped, including:

- Metal: Metal is the most common material used for stamping. It is strong and durable, and can be stamped into a variety of shapes and sizes.

- Plastic: Plastic is a lightweight and flexible material that is often used for stamping. It is less durable than metal, but it is also less expensive.

- Wood: Wood is a natural material that can be stamped into a variety of shapes and sizes. It is less durable than metal or plastic, but it is also less expensive.

4. What are the different types of finishes that can be applied to stamped parts?

A variety of finishes can be applied to stamped parts, including:

- Plating: Plating is a process of coating a metal part with a thin layer of another metal. This can be done to improve the part’s corrosion resistance, wear resistance, or appearance.

- Painting: Painting is a process of applying a thin layer of paint to a part. This can be done to improve the part’s appearance, protect it from corrosion, or make it more visible.

- Powder coating: Powder coating is a process of applying a dry powder to a part. The powder is then heated, causing it to melt and bond to the part’s surface. This can provide a durable and attractive finish.

5. What are the different types of quality control measures that can be used for stamped parts?

A variety of quality control measures can be used for stamped parts, including:

- Visual inspection: This is the most basic type of quality control measure and involves visually inspecting the part for any defects.

- Dimensional inspection: This type of quality control measure involves measuring the part’s dimensions to ensure that they meet the specified requirements.

- Functional testing: This type of quality control measure involves testing the part to ensure that it functions properly.

6. What are the different types of safety precautions that should be taken when operating a machine stamper?

A variety of safety precautions should be taken when operating a machine stamper, including:

- Wear proper safety gear: This includes wearing safety glasses, gloves, and earplugs.

- Keep your hands away from the moving parts: This includes the punch, die, and transfer plate.

- Never operate the stamper if it is not properly guarded: The guards are there to protect you from injury.

- Follow all of the manufacturer’s instructions: This includes the instructions for operating the stamper, as well as the instructions for maintaining it.

7. What are the different types of maintenance tasks that need to be performed on a machine stamper?

A variety of maintenance tasks need to be performed on a machine stamper, including:

- Regular lubrication: This helps to keep the moving parts of the stamper running smoothly.

- Inspection of the punch and die: This helps to ensure that the punch and die are in good condition and that they are not damaged.

- Replacement of worn parts: This helps to keep the stamper running properly and to prevent breakdowns.

8. What are the different types of troubleshooting techniques that can be used to fix a machine stamper?

A variety of troubleshooting techniques can be used to fix a machine stamper, including:

- Visual inspection: This is the most basic troubleshooting technique and involves visually inspecting the stamper for any obvious problems.

- Electrical testing: This type of troubleshooting technique involves using a multimeter to test the electrical components of the stamper.

- Mechanical testing: This type of troubleshooting technique involves using a variety of tools to test the mechanical components of the stamper.

9. What are the different types of training programs that can be used to train a machine stamper operator?

A variety of training programs can be used to train a machine stamper operator, including:

- On-the-job training: This type of training involves learning how to operate the stamper on the job under the supervision of an experienced operator.

- Classroom training: This type of training involves learning about the theory of stamping in a classroom setting.

- Online training: This type of training involves learning about stamping through online courses.

10. What are the different types of career advancement opportunities that are available to a machine stamper operator?

A variety of career advancement opportunities are available to a machine stamper operator, including:

- Supervisor: This position involves supervising a team of machine stamper operators.

- Quality control inspector: This position involves inspecting stamped parts to ensure that they meet the specified requirements.

- Maintenance technician: This position involves maintaining and repairing machine stampers.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Stamper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Stamper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities for a Machine Stamper

Machine Stampers fulfill a critical role in the manufacturing industry, operating specialized machinery to imprint designs on various materials. Their key responsibilities include:

1. Machine Operation

Expertly operate and maintain a variety of stamping machines, ensuring precise and efficient imprinting.

- Set up machines according to specified parameters.

- Feed materials into machines and monitor the stamping process.

- Adjust machine settings and perform routine maintenance to optimize performance.

2. Quality Control

Continuously inspect stamped products to ensure they meet quality standards.

- Identify and resolve any defects or inconsistencies.

- Maintain detailed records of inspection results.

3. Production Management

Effectively manage production schedules to meet deadlines and minimize downtime.

- Monitor production rates and make adjustments as necessary.

- Troubleshoot production issues and implement corrective actions.

4. Safety Compliance

Adhere to all safety regulations and protocols.

- Wear appropriate protective gear and follow established procedures.

- Report any unsafe conditions or practices.

- Maintain a clean and organized work area.

Interview Tips for Acing the Machine Stamper Interview

To make a lasting impression and increase your chances of succeeding in a Machine Stamper interview, consider the following tips:

1. Research the Company and Position

Familiarize yourself with the company’s products, services, and industry standing. Understand the specific requirements of the Machine Stamper role and how your skills align with them.

2. Practice Common Interview Questions

Prepare for typical interview questions such as “Tell me about your experience in machine stamping” and “What are your strengths and weaknesses.” Articulate your answers concisely and highlight your relevant qualifications.

- Example Outline:

- Introduce yourself and briefly mention your experience in machine stamping.

- Explain how your skills and experience match the job requirements.

- Provide specific examples of your accomplishments and contributions.

- Conclude by expressing your enthusiasm for the position and the company.

3. Showcase Your Technical Expertise

Demonstrate your in-depth knowledge of machine stamping techniques, materials, and safety regulations. Discuss your ability to troubleshoot and resolve production issues effectively.

4. Emphasize Your Attention to Detail

Highlight your meticulous nature and unwavering commitment to quality. Explain how you ensure the accuracy and precision of stamped products and maintain a high level of quality control.

5. Be Prepared to Discuss Safety Protocols

Emphasize your adherence to safety regulations and your understanding of the importance of maintaining a safe work environment. Describe your experience in following established safety procedures and reporting any potential hazards.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Machine Stamper interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.