Are you gearing up for a career in Machine Veneer Repairer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Machine Veneer Repairer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

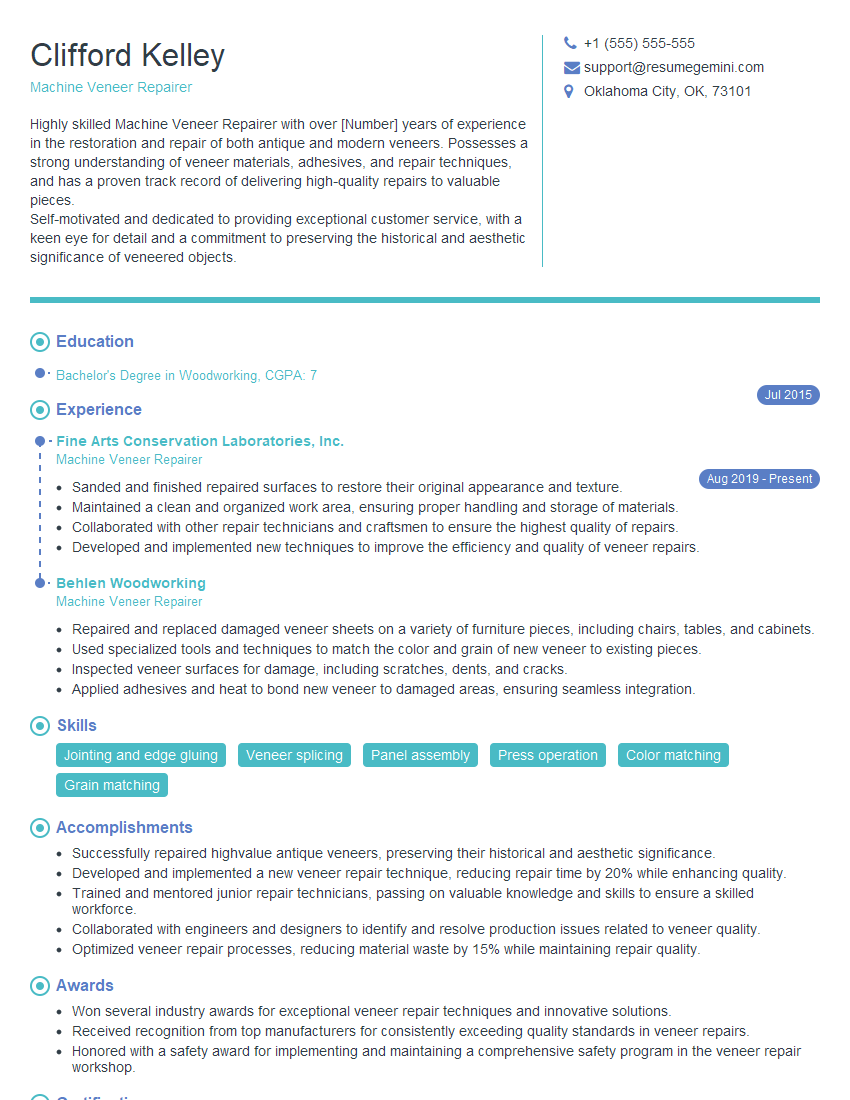

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Veneer Repairer

1. What is the main purpose of a veneer repairer?

- Repair and restore damaged veneer surfaces to their original condition.

- Maintain the aesthetic appeal and structural integrity of wood products.

2. What are the key techniques used in machine veneer repair?

Cutting and Matching:

- Precision cutting techniques to remove damaged veneer.

- Expert matching of new veneers to blend seamlessly with the existing surface.

Pressing and Bonding:

- Applying pressure and heat to bond new veneers securely.

- Achieving a strong and lasting bond that prevents lifting or warping.

Finishing:

- Sanding, staining, and polishing to restore the surface’s texture and color.

- Matching the finish to the surrounding wood for a flawless appearance.

3. What types of damage can a veneer repairer address?

- Dents, scratches, and gouges in veneer surfaces.

- Water damage, such as warping and bubbling.

- Damage caused by heat, sunlight, or chemical exposure.

- Missing or loose veneers.

4. What are the common tools and materials used in veneer repair?

- Veneer saws, chisels, and clamps.

- Adhesives, solvents, and fillers.

- Sandpaper, scrapers, and buffers.

- Replacement veneers in various species and finishes.

5. How do you ensure the quality of your repairs?

- Careful inspection and preparation of the damaged area.

- Precision cutting and matching of replacement veneers.

- Proper application of adhesives and pressure to create a strong bond.

- Thorough finishing to achieve a seamless and natural appearance.

6. What are the safety precautions you take when working with veneers?

- Use sharp tools and machinery with caution.

- Wear appropriate protective gear such as gloves and eye protection.

- Handle adhesives and solvents responsibly, following manufacturer’s guidelines.

- Ensure adequate ventilation when using power tools or finishing materials.

7. What are the industry standards and best practices for veneer repair?

- Adherence to furniture manufacturers’ specifications.

- Use of high-quality materials and adhesives.

- Application of industry-approved repair techniques.

- Maintaining a clean and organized work area.

8. Describe a challenging veneer repair project you encountered and how you resolved it.

Share a specific example of a difficult repair, highlighting your problem-solving skills, technical proficiency, and attention to detail.

9. How do you stay updated with the latest advancements in veneer repair techniques?

- Attend industry events and workshops.

- Read trade publications and online resources.

- Network with other veneer repairers.

- Engage in ongoing research and experimentation.

10. What qualities make you a successful veneer repairer?

- Precision and attention to detail.

- In-depth knowledge of veneer materials and repair techniques.

- Strong problem-solving and analytical skills.

- Excellent communication and interpersonal abilities.

- A commitment to quality and customer satisfaction.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Veneer Repairer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Veneer Repairer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Machine Veneer Repairer is a skilled professional responsible for repairing and maintaining veneer machines. Key job responsibilities include:Maintaining and repairing veneer machines to ensure optimal performance and minimize downtime.

1. Machine Maintenance and Repair

Performing regular maintenance checks and servicing on veneer machines, including greasing, cleaning, and replacing worn or damaged parts.

- Diagnosing and troubleshooting machine malfunctions and performing necessary repairs.

- Adjusting and calibrating machines to maintain precise tolerances and ensure consistent product quality.

2. Veneer Handling and Repair

Handling and inspecting veneer sheets, identifying defects and performing repairs to restore their quality.

- Splicing and patching veneer to fill in missing or damaged sections.

- Applying adhesives and pressure to bond veneer sections securely.

3. Quality Control and Inspection

Inspecting repaired veneer sheets to ensure they meet quality standards, including thickness, grain matching, and surface finish.

- Identifying and rejecting non-conforming veneer sheets to maintain product quality.

- Documenting repair work and maintaining detailed records.

4. Safety and Housekeeping

Maintaining a clean and safe work area, following safety protocols and using appropriate protective gear.

- Complying with environmental regulations and handling hazardous materials with care.

- Reporting any potential hazards or safety concerns.

Interview Tips

Thoroughly research the company and the Machine Veneer Repairer position to gain an understanding of the specific requirements and responsibilities.

1. Prepare for Technical Questions

Practice answering technical questions related to veneer repair, machine maintenance, and quality control.

- Be familiar with different types of veneer machines and their functionality.

- Explain your approach to troubleshooting and repairing machine malfunctions.

2. Highlight Your Experience and Skills

Showcase your relevant experience and skills in veneer repair and machine maintenance.

- Emphasize your ability to identify and address veneer defects.

- Quantify your accomplishments, such as reducing machine downtime or improving productivity.

3. Demonstrate Attention to Detail

Convey your meticulous attention to detail and commitment to quality.

- Explain your quality control processes and how you ensure the accuracy and precision of your work.

- Provide examples of how you have identified and corrected errors or defects.

4. Emphasize Safety and Compliance

Stress your adherence to safety regulations and environmental best practices.

- Discuss your experience in maintaining a clean and safe work environment.

- Demonstrate your understanding of relevant regulations and how you comply with them.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Machine Veneer Repairer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Machine Veneer Repairer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.