Feeling lost in a sea of interview questions? Landed that dream interview for Mill Worker but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Mill Worker interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

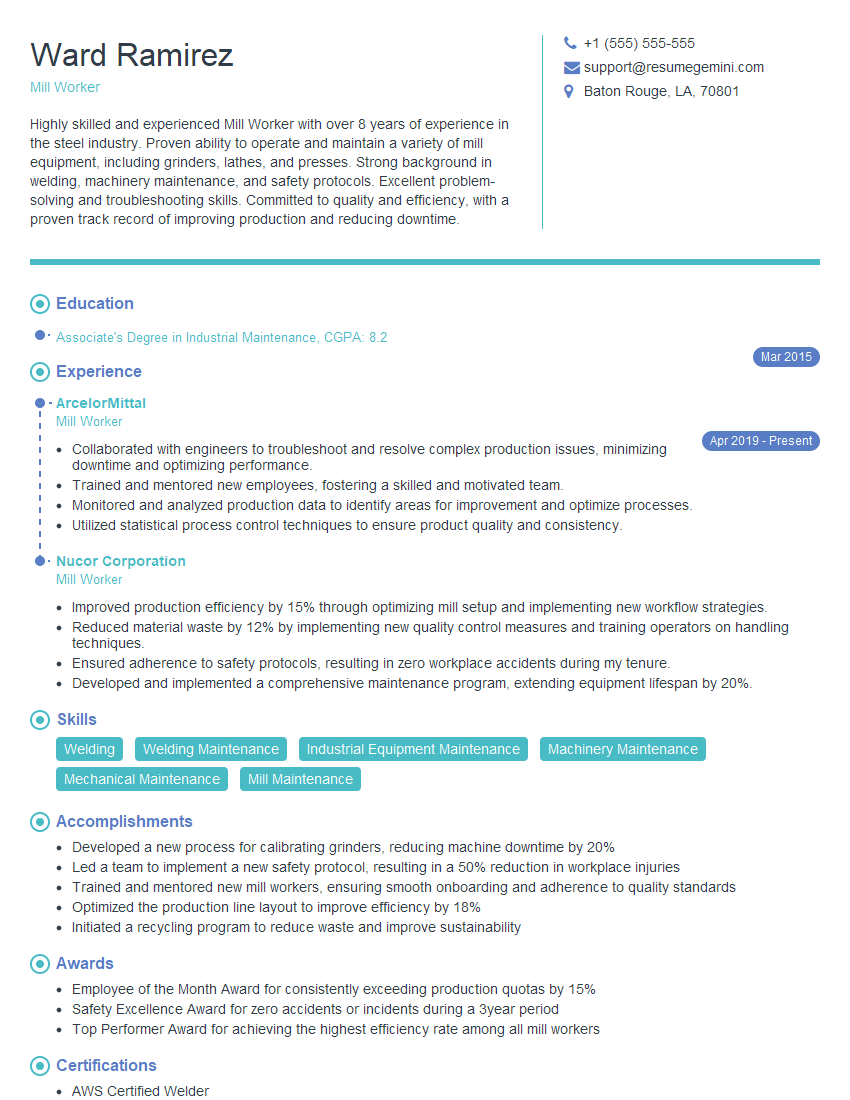

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mill Worker

1. What are the different types of milling machines and their applications?

- Horizontal milling machine

- Vertical milling machine

- Knee-type milling machine

- Bed-type milling machine

- Column and knee milling machine

- Gang milling machine

- Planer milling machine

- Profile milling machine

- Turret milling machine

2. What are the different types of milling cutters and their uses?

Cutting operations performed by each cutter

- End mill: Used for milling flat surfaces, slots, and pockets.

- Face mill: Used for milling large flat surfaces.

- Ball mill: Used for milling curved surfaces.

- Shell mill: Used for milling large flat surfaces and pockets.

- Slot mill: Used for milling slots.

- Form mill: Used for milling specific shapes.

Material of the cutters

- High-speed steel (HSS)

- Carbide

- Ceramic

- Diamond

3. What are the factors that affect the surface finish in milling?

- Feed rate

- Cutting speed

- Depth of cut

- Tool geometry

- Workpiece material

- Machine condition

4. What are the safety precautions that must be taken while operating a milling machine?

- Wear appropriate safety gear, including safety glasses, earplugs, and gloves.

- Make sure the machine is properly grounded.

- Secure the workpiece properly.

- Keep hands and clothing away from moving parts.

- Use sharp cutting tools.

- Never operate the machine while under the influence of alcohol or drugs.

5. What are the different types of coolants used in milling and their advantages and disadvantages?

- Oil-based coolants: Advantages: Good lubrication, high cooling capacity. Disadvantages: Can be messy, can cause skin irritation.

- Water-based coolants: Advantages: Non-flammable, non-toxic, inexpensive. Disadvantages: Can cause rust, poor lubrication.

- Synthetic coolants: Advantages: Good lubrication, high cooling capacity, non-flammable. Disadvantages: Can be expensive.

6. What is the purpose of a collet in a milling machine?

- To hold the cutting tool securely

- To allow for quick and easy tool changes

- To absorb vibration

- To prevent damage to the cutting tool

7. What is the difference between climb milling and conventional milling?

- Climb milling: The cutting tool moves in the same direction as the workpiece.

- Conventional milling: The cutting tool moves in the opposite direction as the workpiece.

Advantages of climb milling

- Higher cutting forces

- Better surface finish

- Reduced tool wear

Advantages of conventional milling

- Lower cutting forces

- Easier to control

- Less likely to cause chatter

8. What is the importance of tool life in milling?

- Tool life affects the cost of production.

- Tool life affects the quality of the finished product.

- Tool life affects the productivity of the milling operation.

9. How can you troubleshoot a milling machine that is not producing the desired results?

- Check the cutting tool for wear or damage.

- Check the workpiece for proper setup and securement.

- Check the machine settings for accuracy.

- Check the coolant supply.

- Check the machine for any mechanical problems.

10. What is your experience with using CAD/CAM software in milling?

- I am proficient in using CAD/CAM software for milling.

- I have used CAD/CAM software to create toolpaths for a variety of milling operations.

- I have used CAD/CAM software to simulate milling operations.

- I am familiar with the different file formats used in CAD/CAM software.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mill Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mill Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities: Mill Worker

Mill Workers operate machines and equipment in a variety of industrial environments, such as lumber mills, paper mills, steel mills, and chemical plants. They perform a wide range of tasks to ensure that production is efficient and safe.

1. Machine Operation

Mill Workers are responsible for operating a variety of machines, including saws, grinders, lathes, and conveyors. They must be able to follow instructions and work safely with machinery.

- Operate and maintain machines to meet production quotas.

- Monitor machine performance and make adjustments as needed.

2. Material Handling

Mill Workers handle raw materials and finished products. They must be able to lift heavy objects and work in a fast-paced environment.

- Move materials throughout the production process.

- Load and unload machines

3. Safety and Maintenance

Mill Workers must be aware of safety procedures and follow them at all times. They must also be able to perform basic maintenance on equipment.

- Follow safety procedures and wear appropriate safety gear.

- Clean and maintain equipment.

4. Quality Inspection

Mill Workers may be responsible for inspecting raw materials and finished products. They must be able to identify defects and ensure that products meet quality standards.

- Inspect raw materials and finished products for defects.

- Identify and correct problems.

Interview Tips for Mill Workers

Preparing for a mill worker interview requires a good understanding of the role and its key responsibilities, as well as the ability to present yourself as a suitable candidate. Here are some tips to help you ace your interview.

1. Research the Company and Position

Before the interview, take some time to research the company and the specific mill worker position you are applying for. This will help you understand the company’s culture, values, and specific needs.

- Visit the company’s website to learn about their history, mission, and products/services.

- Read industry news and articles to stay up-to-date on the latest trends and technologies.

2. Highlight Relevant Skills and Experience

In your resume and interview, be sure to highlight the skills and experience that are most relevant to the mill worker position. This may include your experience operating machines, handling materials, or working in a safety-conscious environment.

- Quantify your accomplishments and use specific examples to demonstrate your skills.

- Tailor your resume and cover letter to each specific job you apply for, highlighting the skills and experience that are most relevant to the position.

3. Practice Common Interview Questions

There are some common interview questions that you are likely to be asked in a mill worker interview. Take some time to practice answering these questions before the interview, so that you can deliver confident and well-thought-out responses.

- Tell me about yourself.

- Why are you interested in working as a mill worker?

- What are your strengths and weaknesses?

- What is your experience with operating machinery?

- How do you handle working in a fast-paced environment?

- What are your safety procedures when working with machinery?

4. Be Enthusiastic and Professional

The interview is your chance to make a good impression on the hiring manager and show them why you are the best candidate for the job. Be enthusiastic and professional throughout the interview, and be sure to ask questions about the company and the position.

- Dress appropriately for the interview.

- Be on time for your interview.

- Make eye contact with the interviewer and speak clearly.

Next Step:

Now that you’re armed with the knowledge of Mill Worker interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Mill Worker positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini