Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Milled Rubber Tender position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

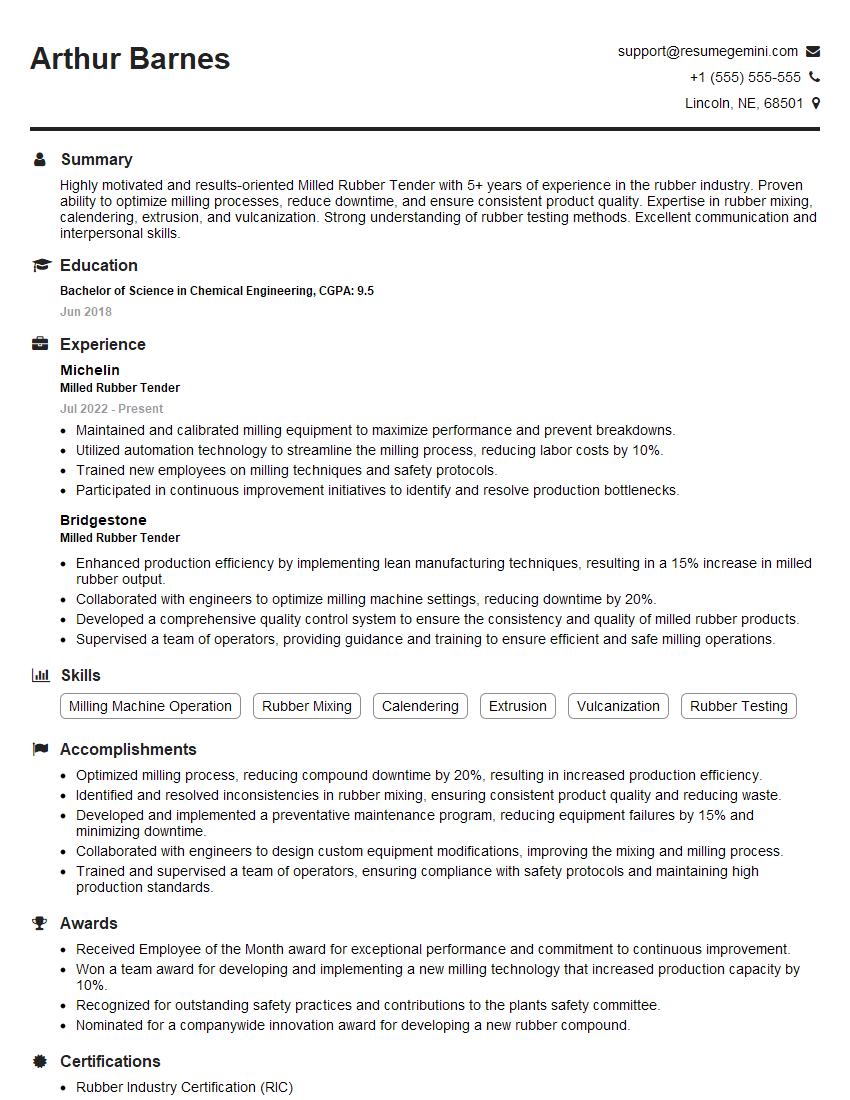

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Milled Rubber Tender

1. What are the key responsibilities of a Milled Rubber Tender?

- Operate rubber milling machines to mill and blend raw rubber compounds.

- Control processing parameters to ensure the production of rubber compounds with the required specifications.

- Monitor and maintain rubber milling equipment, including cleaning and adjusting machinery when necessary.

- Perform quality control tests on rubber compounds to ensure adherence to standards.

- Maintain a clean and organized work area, following safety protocols.

2. Describe the different types of rubber milling machines and their applications.

Sheeting Mills

- Used to produce rubber sheets and slabs.

- Characterized by two large, rotating rolls that compress and flatten the rubber.

Banbury Mixers

- Used for mixing and blending rubber compounds with additives and chemicals.

- Feature a rotating chamber with blades that shear and mix the ingredients.

Roller Mills

- Used to refine and homogenize rubber compounds.

- Consist of several pairs of rotating rolls that gradually reduce the particle size of the rubber.

3. How do you ensure the quality of rubber compounds produced on the milling machine?

- Follow established process parameters and specifications.

- Monitor the temperature, pressure, and other critical variables during milling.

- Conduct regular quality control tests, such as Mooney viscosity, plasticity, and tensile strength.

- Inspect the rubber compounds for defects and non-uniformity.

- Make necessary adjustments to the milling process to maintain the desired quality standards.

4. How do you handle and resolve technical issues that arise during the milling process?

- Identify the root cause of the issue through observation and analysis.

- Refer to technical documentation or consult with experienced colleagues.

- Implement appropriate corrective actions, such as adjusting machine settings, cleaning components, or replacing worn parts.

- Monitor the results and make further adjustments if necessary.

- Document the issue and resolution for future reference.

5. What safety precautions and procedures must be followed when operating rubber milling machines?

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and earplugs.

- Ensure that the machine is properly grounded and guarded.

- Keep the work area clean and free of tripping hazards.

- Never attempt to clear jams or unclog the machine while it is running.

- Follow established lockout/tagout procedures when performing maintenance or repairs.

6. How do you maintain and calibrate the rubber milling machines to ensure optimal performance?

- Conduct regular visual inspections for wear and tear.

- Clean and lubricate moving parts according to the manufacturer’s recommendations.

- Calibrate sensors and gauges to ensure accurate measurements.

- Follow preventive maintenance schedules to replace worn components and extend the life of the equipment.

- Keep a maintenance log to track inspections, repairs, and calibrations.

7. What experience do you have in optimizing the rubber milling process to improve efficiency and reduce waste?

- Experimented with different milling parameters, such as temperature, pressure, and roll speed.

- Analyzed data to identify areas for improvement and implemented changes.

- Collaborated with other team members to find innovative solutions to reduce waste and increase productivity.

- Successfully implemented process improvements that resulted in increased efficiency and reduced costs.

8. How do you stay updated with the latest advancements and best practices in rubber milling technology?

- Attend industry conferences and seminars.

- Read technical journals and white papers.

- Network with other professionals in the field.

- Participate in online forums and discussions.

- Research and explore new techniques and technologies.

9. Describe a challenging situation you faced as a Milled Rubber Tender and how you overcame it.

- Presented the challenge in detail, including the specific issue and the impact it had on the production process.

- Explained the steps taken to identify the root cause of the problem.

- Discussed the solutions implemented and the positive outcomes achieved.

- Emphasized the technical skills and problem-solving abilities employed.

10. Why are you interested in working as a Milled Rubber Tender in our company?

- Expressed interest in the company’s reputation and industry standing.

- Highlighted the alignment of skills and experience with the job requirements.

- Demonstrated enthusiasm for the role and the opportunity to contribute to the team.

- Emphasized the desire to grow professionally and take on new challenges.

- Expressed willingness to learn and adapt to the specific requirements of the company.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Milled Rubber Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Milled Rubber Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Milled Rubber Tender is responsible for operating machinery to produce milled rubber products, ensuring that the production process meets quality standards and safety regulations. Key responsibilities include:

1. Rubber Production

Operate milling machines to crush and refine raw rubber into a specified consistency and particle size.

- Monitor and adjust machine settings to maintain optimal production rates and quality.

- Inspect milled rubber for consistency, particle size, and color.

- Ensure that milled rubber meets customer specifications and industry standards.

2. Equipment Maintenance

Perform routine maintenance and cleaning of milling machinery to ensure optimal performance.

- Lubricate moving parts, replace worn components, and calibrate sensors.

- Identify and troubleshoot equipment malfunctions, and take corrective actions.

- Maintain a clean and organized work area, adhering to safety protocols.

3. Raw Material Handling

Handle and store raw rubber materials, ensuring proper inventory management.

- Unload raw rubber bales, check for quality, and store them appropriately.

- Monitor raw material inventory levels and coordinate with suppliers for replenishment.

- Maintain accurate records of raw material usage and production output.

4. Quality Control

Implement and maintain quality control procedures to ensure the production of high-quality milled rubber.

- Conduct regular inspections of milled rubber products, checking for defects and deviations.

- Analyze test results and make adjustments to the production process as needed.

- Document quality control activities and maintain records for traceability.

Interview Tips

To prepare for an interview for a Milled Rubber Tender position, consider the following tips:

1. Research the Company and Industry

Familiarize yourself with the company’s products, operations, and industry trends. This will demonstrate your interest in the role and the company.

- Visit the company’s website and LinkedIn page.

- Read industry publications and news articles.

- Network with professionals in the rubber manufacturing field.

2. Highlight Relevant Experience and Skills

Emphasize your hands-on experience operating milling machinery, performing quality control inspections, and maintaining production equipment.

- Quantify your accomplishments whenever possible, using specific numbers and data.

- Showcase your ability to work independently and as part of a team.

- Demonstrate your attention to detail and commitment to quality.

3. Prepare for Technical Questions

Expect to encounter technical questions related to rubber milling processes, equipment operation, and quality control procedures.

- Review the basics of rubber milling and the different types of milling machines used.

- Familiarize yourself with the various quality control tests performed on milled rubber.

- Be prepared to discuss your troubleshooting skills and experience resolving equipment issues.

4. Practice Common Interview Questions

Prepare answers to common interview questions such as:

- “Tell me about your experience with milled rubber production.”

- “Describe a situation where you identified and resolved a quality issue.”

- “How do you stay up-to-date with the latest advancements in rubber milling technology?”

Next Step:

Now that you’re armed with the knowledge of Milled Rubber Tender interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Milled Rubber Tender positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini