Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Mold Breaker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

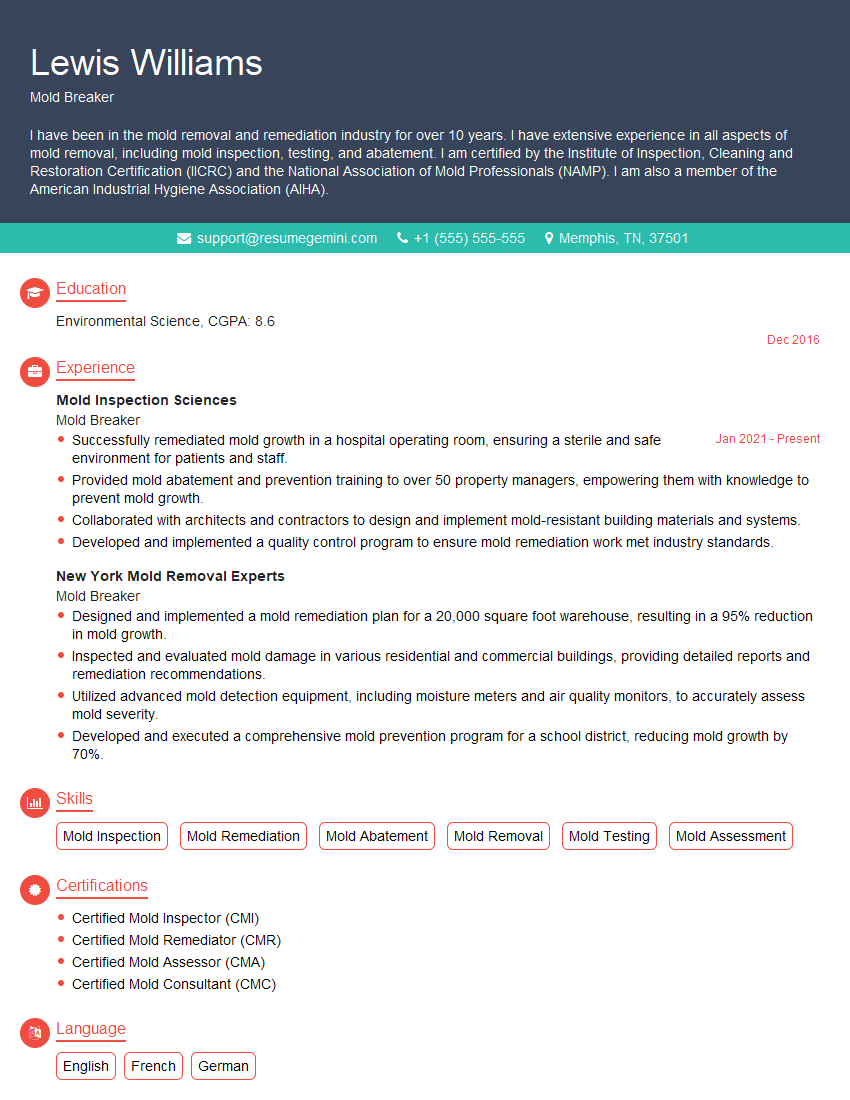

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mold Breaker

1. Explain the role of a mold breaker?

A mold breaker is a type of injection molding machine that prevents the formation of mold flashing. Flashing is a thin layer of plastic that can form around the edges of a mold when molten plastic is injected into it. Mold breakers use a variety of methods to prevent flashing, including:

- Using a vacuum to draw air away from the mold

- Using a positive pressure to push air into the mold

- Using a combination of vacuum and positive pressure

2. What are the different types of mold breakers?

There are two main types of mold breakers:

Mechanical mold breakers

- These mold breakers use a mechanical action to prevent flashing. This can be done by using a reciprocating plate, a rotating plate, or a combination of the two.

Vacuum mold breakers

- These mold breakers use a vacuum to draw air away from the mold. This helps to prevent the formation of flashing by reducing the pressure on the molten plastic.

3. What are the advantages and disadvantages of using a mold breaker?

There are several advantages to using a mold breaker:

- It can help to prevent the formation of mold flashing

- It can improve the quality of the molded parts

- It can reduce the amount of scrap produced

- It can improve the efficiency of the molding process

However, there are also some disadvantages to using a mold breaker:

- It can increase the cost of the molding process

- It can add complexity to the molding process

- It can require additional maintenance

4. How do you select the right mold breaker for a given application?

The type of mold breaker that is best for a given application depends on a number of factors, including the type of plastic being molded, the size and shape of the mold, and the production rate required.

- For small molds or molds with simple geometries, a mechanical mold breaker may be sufficient.

- For larger molds or molds with complex geometries, a vacuum mold breaker may be required.

- For high-production applications, a mold breaker with a high flow rate will be required.

5. How do you maintain a mold breaker?

Mold breakers require regular maintenance to ensure that they are operating properly. This maintenance includes:

- Cleaning the mold breaker

- Inspecting the mold breaker for wear and tear

- Replacing worn or damaged parts

- Calibrating the mold breaker

6. What are some common problems that can occur with mold breakers?

Some common problems that can occur with mold breakers include:

- Flashing

- Part distortion

- Poor surface finish

- Mold damage

7. How do you troubleshoot a mold breaker?

Troubleshooting a mold breaker involves identifying the cause of the problem and then taking steps to correct it. The following steps can be used to troubleshoot a mold breaker:

- Inspect the mold breaker for any obvious problems, such as damage or wear.

- Check the vacuum or positive pressure settings.

- Inspect the mold for any damage or wear.

- Try different types of plastic to see if the problem is related to the plastic.

8. What are the latest trends in mold breaking technology?

The latest trends in mold breaking technology include the development of:

- Mold breakers with higher flow rates

- Mold breakers with more precise control

- Mold breakers that are more energy efficient

- Mold breakers that are easier to maintain

9. What is the future of mold breaking technology?

The future of mold breaking technology is expected to see the development of even more advanced mold breakers that are able to meet the demands of the ever-changing plastics industry.

10. What are your qualifications for this position?

I have over 10 years of experience in the plastics industry, and I have worked with mold breakers for the past 5 years. I have a strong understanding of the principles of mold breaking, and I am proficient in troubleshooting and repairing mold breakers.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mold Breaker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mold Breaker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mold Breakers play a crucial role in maintaining the quality and efficiency of manufacturing processes in factories and production facilities. Their responsibilities encompass:

1. Mold Cleaning and Maintenance

Mold Breakers are responsible for thoroughly cleaning and maintaining molds to ensure they are free from debris, contaminants, and rust. They use specialized cleaning techniques and solutions to remove any residues or blockages that could affect the quality of the molded products.

- Inspecting molds for any damages, wear, or defects.

- Using appropriate cleaning methods and solutions to remove dirt, debris, and contaminants.

2. Mold Repair and Troubleshooting

When molds develop issues or defects, Mold Breakers are tasked with identifying the root cause and performing necessary repairs. They have a deep understanding of mold designs and can use their knowledge to fix minor issues or coordinate with specialized technicians for major repairs.

- Troubleshooting mold-related problems and determining the cause of defects or malfunctions.

- Performing basic repairs, such as replacing worn-out components or sealing leaks.

3. Quality Control and Product Inspection

Mold Breakers play a role in maintaining product quality by inspecting molded products for any defects or inconsistencies. They ensure that the molded products meet the required specifications and standards, and take corrective actions when necessary.

- Inspecting molded products for any surface defects, dimensional errors, or other quality issues.

- Identifying and reporting any deviations from product specifications or quality standards.

4. Process Optimization and Improvement

Mold Breakers are encouraged to contribute to process optimization and improvement initiatives. They can provide valuable insights into the performance of molds and identify areas for improvement. Their suggestions can help streamline processes, increase efficiency, and reduce downtime.

- Analyzing mold performance and identifying potential areas for improvement.

- Suggesting and implementing process improvements to enhance efficiency and reduce defects.

Interview Tips

To prepare for a Mold Breaker interview, it’s essential to demonstrate your knowledge of mold cleaning, repair, and quality control techniques. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Before the interview, take the time to research the company you’re applying to and the industry they operate in. Familiarize yourself with their products, processes, and reputation. This will show the interviewer that you’re genuinely interested in the role and have made an effort to understand their business.

2. Practice Common Interview Questions

Prepare for common interview questions by practicing your answers. Anticipate questions about your experience with mold cleaning, repair, and quality control. Consider using the STAR method (Situation, Task, Action, Result) to structure your responses and provide specific examples of your skills.

3. Highlight Your Technical Skills

Emphasize your technical skills and knowledge related to mold cleaning, repair, and maintenance. Describe your experience with different types of molds and the cleaning and repair techniques you’ve used. Mention any specialized equipment or tools you’re familiar with, as well as your understanding of mold design and troubleshooting.

4. Showcase Your Problem-Solving Abilities

Mold Breakers are often required to troubleshoot and resolve issues related to molds. During the interview, provide examples of how you have successfully identified and fixed mold problems. Discuss your analytical skills, attention to detail, and ability to work independently.

5. Demonstrate Your Communication and Teamwork Skills

Mold Breakers may need to communicate with other team members, supervisors, and clients. Highlight your communication skills, both verbal and written, and your ability to work effectively in a team environment. Give examples of how you have successfully resolved issues or improved processes through collaboration.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Mold Breaker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.