Are you gearing up for a career in Paint Roller Assembler? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Paint Roller Assembler and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

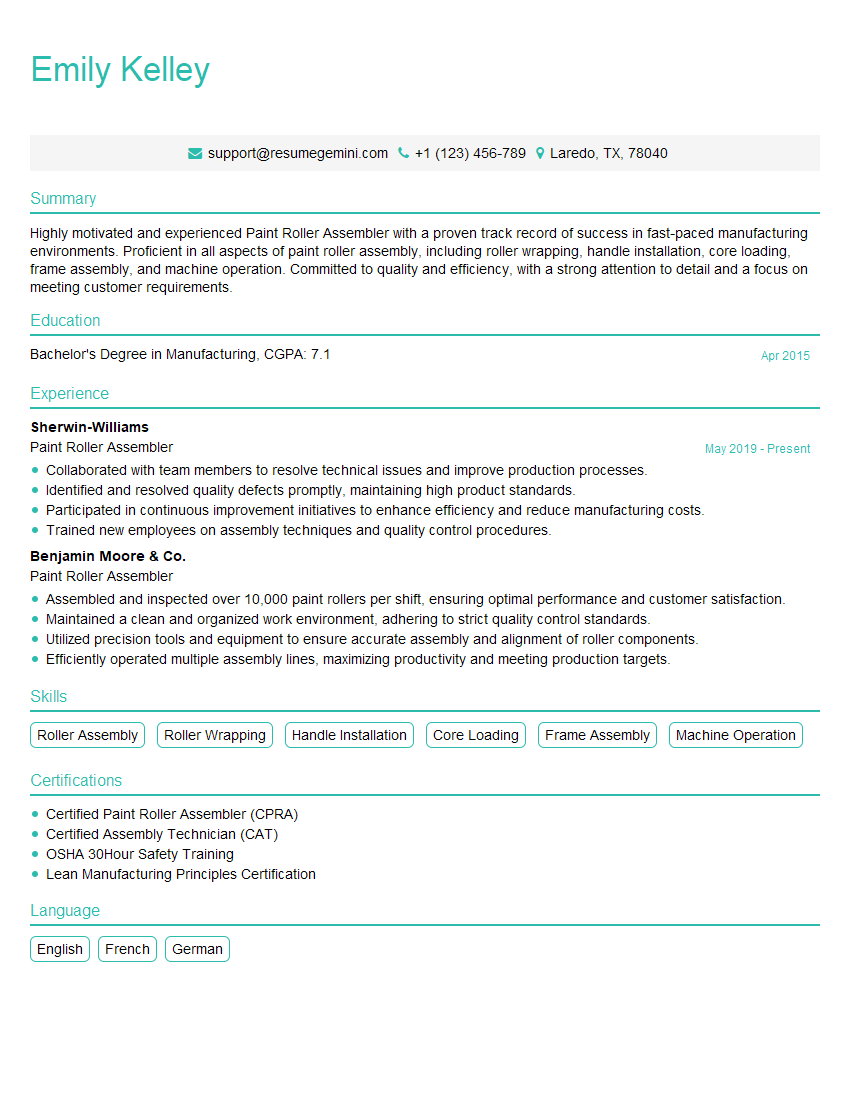

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Paint Roller Assembler

1. Which are the different types of paint roller covers, and what are their applications?

There are several types of paint roller covers, each designed for specific applications. Here are a few common types:

- Natural fiber covers, such as mohair and lambswool, provide a smooth finish and are suitable for most paints and primers.

- Synthetic fiber covers, such as nylon and polyester, are more durable and resistant to wear, making them ideal for rough surfaces and heavy-duty applications.

- Foam covers are absorbent and provide a thick, even coat, making them suitable for textured surfaces and applying thick paints or stains.

- Specialty covers, such as flocked or abrasive covers, are designed for specific purposes, such as applying texture or removing old paint.

2. What are the critical factors to consider when choosing the right paint roller size for a project?

Roller cover nap length

- Short naps (1/4 inch or less) are suitable for smooth surfaces and thin paints.

- Medium naps (3/8 to 1/2 inch) are versatile and can be used for a wider range of surfaces and paints.

- Long naps (1 inch or more) are recommended for rough or textured surfaces and thick paints or stains.

Roller cover width

- Narrow rollers (4-6 inches wide) are suitable for tight spaces and detailed work.

- Medium rollers (7-9 inches wide) are a good all-purpose size for most projects.

- Wide rollers (10-12 inches wide) are efficient for covering large areas quickly.

3. How do you ensure the paint roller is properly loaded and avoid excessive dripping?

- Pour paint into the roller tray and spread it evenly over the sloped area.

- Roll the roller into the paint, covering it completely but not overloading it.

- Roll the roller back and forth on the sloping area to distribute the paint evenly and remove excess.

- Gently tap the roller on the edge of the tray to remove any remaining drips.

4. What are the techniques for applying paint evenly and avoiding lap marks?

- Start by rolling the paint onto the surface in a W or M pattern to ensure even coverage.

- Overlap each stroke slightly to avoid visible lines.

- Apply light pressure and roll the paint in the same direction to prevent lap marks.

- For large areas, divide the surface into sections and work on one section at a time to maintain a wet edge.

5. What are the safety precautions to observe when using paint rollers?

- Wear appropriate protective gear, including gloves, eye protection, and a mask.

- Ensure adequate ventilation in the work area.

- Use a step stool or ladder safely when working on elevated surfaces.

- Dispose of used paint rollers and materials according to local regulations.

- Keep paint away from children and pets.

6. How do you clean and maintain paint rollers after use?

- Immediately remove excess paint by rolling the roller over a piece of cardboard or paper.

- Rinse the roller thoroughly with warm water or a paint roller cleaner.

- Spin the roller to remove as much water as possible.

- Wrap the roller in a damp cloth or store it in a plastic bag to prevent it from drying out completely.

- Clean the roller tray and other tools thoroughly.

7. What are the common defects or problems that can occur when using paint rollers, and how do you troubleshoot them?

- Air bubbles: caused by applying paint too quickly or using a roller with an overly long nap; reduce the nap length and apply paint more slowly.

- Lap marks: caused by overlapping strokes too much or applying paint unevenly; overlap strokes slightly and roll in the same direction.

- Roller shedding: caused by using old or damaged rollers; replace the roller or remove any loose fibers before use.

- Paint runs: caused by applying too much paint or using a roller with an overly short nap; reduce the paint application or use a roller with a longer nap.

8. What techniques do you use to achieve specific finishes, such as stippling or faux finishes?

- Stippling: Use a sponge roller or a stippling brush to create a textured finish by dabbing or pouncing the paint onto the surface.

- Faux finishes: Use different techniques, such as sponging, ragging, or combing, to create the illusion of natural textures like marble, wood, or leather.

- Glazing: Apply thin, transparent layers of paint to create depth and color variation.

9. What are the different types of paint roller frames, and how do you choose the right frame for a particular project?

- Fixed-head frames are less adjustable but more rigid and suitable for smaller projects or detailed work.

- Adjustable-head frames allow for different roller sizes and angles, making them more versatile for various projects.

- Extension poles can be attached to frames to extend their reach for high walls or ceilings.

- Consider the size of the project, the surface texture, and the type of paint being used when selecting a frame.

10. How do you handle situations where you encounter uneven surfaces or obstacles during painting?

When encountering uneven surfaces, use a roller with a longer nap to fill in the irregularities. For obstacles, mask them off carefully to prevent paint from getting on them. If painting around moldings or trim, use a small brush or roller to get into the tight spaces.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Paint Roller Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Paint Roller Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Paint Roller Assembler is responsible for the assembly of paint rollers. They play a vital role in the manufacturing process, ensuring that the rollers are properly constructed and ready for use by painters. The key job responsibilities of a Paint Roller Assembler typically include:

1. Assembly of Paint Rollers

Assembling paint rollers involves putting together various components, such as the roller cover, the core, and the handle. The assembler must ensure that all components are properly aligned and secured, resulting in a well-functioning roller.

- Follow assembly instructions and specifications

- Attach roller covers to cores using adhesives or mechanical fasteners

- Insert handles into cores and secure them

2. Inspection of Assembled Rollers

Once the rollers are assembled, they need to be inspected to ensure they meet quality standards. The assembler checks for defects, such as loose components or uneven roller covers. They also verify that the rollers are the correct size and type.

- Visually inspect assembled rollers for defects

- Measure rollers to ensure they meet specifications

- Test rollers to verify proper function

3. Packaging and Labeling of Rollers

After inspection, the assembled rollers are packaged and labeled. The assembler places the rollers in appropriate packaging and applies labels with product information, such as the type of roller, size, and manufacturer.

- Package assembled rollers in boxes or other containers

- Apply labels with product information

- Ensure proper handling and storage of packaged rollers

4. Maintenance of Assembly Line

To ensure efficient production, the assembler is responsible for maintaining the assembly line. They clean and lubricate equipment, and they make minor repairs as needed. They also monitor the line to identify any potential issues and take corrective action.

- Clean and lubricate assembly equipment

- Perform minor repairs and adjustments

- Monitor assembly line for potential issues

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some interview tips and hacks that can help you ace your interview for a Paint Roller Assembler position:

1. Research the Company and the Position

Before the interview, take the time to research the company and the specific Paint Roller Assembler position. This will give you a good understanding of the company’s culture, values, and the specific requirements of the role. You can find this information on the company’s website, social media pages, and job posting.

- Visit the company’s website to learn about their history, mission, and products.

- Check the company’s social media pages to get a sense of their culture and values.

- Read the job posting carefully to understand the specific requirements of the role.

2. Practice Answering Common Interview Questions

There are some common interview questions that you are likely to be asked, regardless of the position you are applying for. It is helpful to practice answering these questions in advance so that you can deliver confident and well-thought-out responses during the interview. Some common interview questions include:

- “Tell me about yourself.”

- “Why are you interested in this position?”

- “What are your strengths and weaknesses?”

3. Prepare Questions to Ask the Interviewer

At the end of the interview, the interviewer will likely ask if you have any questions. This is your opportunity to learn more about the position and the company, and to show the interviewer that you are engaged and interested in the role. Some good questions to ask include:

- “What are the biggest challenges facing the company right now?”

- “What are the opportunities for advancement within the company?”

- “What is the company culture like?”

4. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally for your interview. You should also arrive on time, or even a few minutes early, to show that you are respectful of the interviewer’s time. Punctuality and a professional appearance demonstrate that you are serious about the position and that you are a responsible and reliable candidate.

- Choose clothing that is clean, pressed, and appropriate for a professional setting.

- Arrive for your interview at least 5-10 minutes early.

Next Step:

Now that you’re armed with the knowledge of Paint Roller Assembler interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Paint Roller Assembler positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini