Are you gearing up for an interview for a Panel Laminator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Panel Laminator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

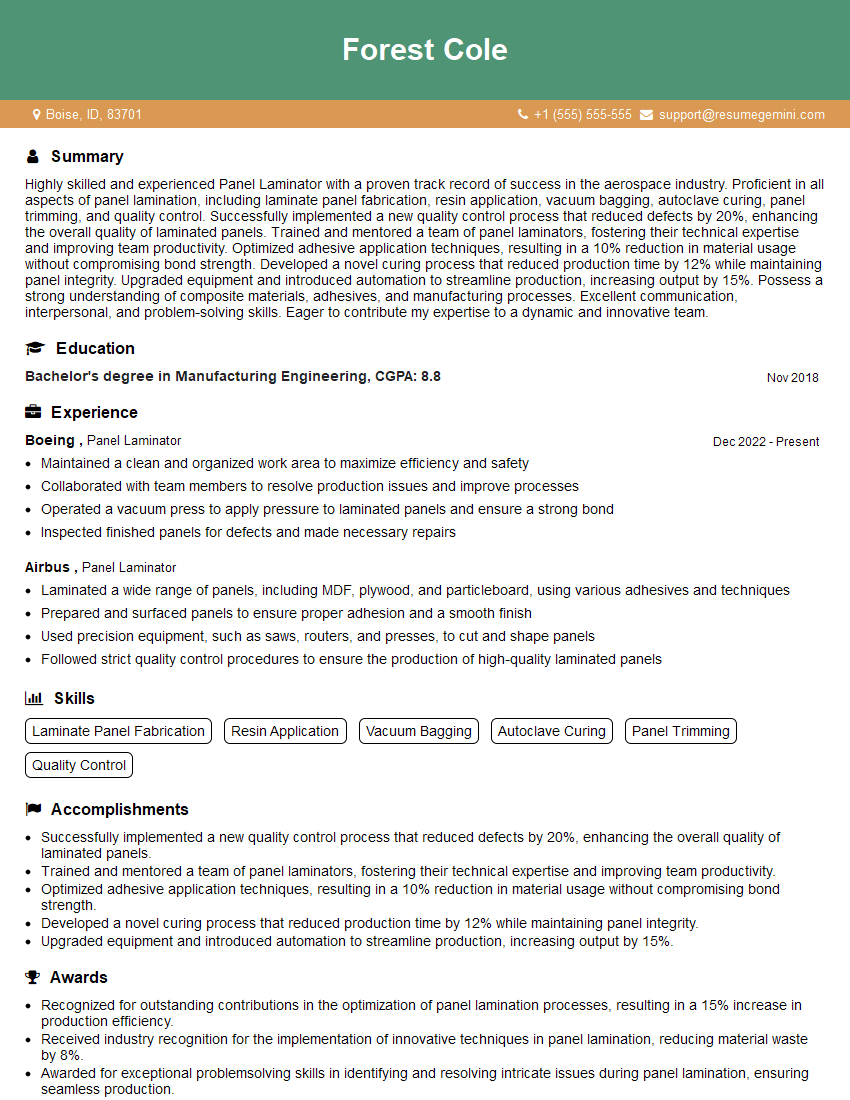

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Panel Laminator

1. What are the different types of panel laminates available?

There are three main types of panel laminates available:

- High-pressure laminates (HPL)

- Low-pressure laminates (LPL)

- Compact laminates (CPL)

2. What are the advantages and disadvantages of using HPL?

Advantages:

- Durable

- Resistant to wear and tear

- Easy to clean

- Wide range of colors and finishes available

Disadvantages:

- Expensive

- Difficult to repair

3. What are the applications of LPL?

LPL is commonly used in applications where durability and cost are important factors, such as:

- Countertops

- Cabinets

- Flooring

- Wall panels

4. What is the difference between CPL and HPL?

- CPL is a denser and more durable laminate than HPL.

- CPL is also more resistant to heat and moisture than HPL.

- HPL is available in a wider range of colors and finishes than CPL.

5. What are the different adhesives used in panel lamination?

The following adhesives are commonly used in panel lamination:

- Polyvinyl acetate (PVA)

- Hot melt adhesives

- Epoxy adhesives

- Polyurethane adhesives

6. What are the factors to consider when selecting an adhesive for panel lamination?

- Type of substrate

- Environmental conditions

- Bond strength requirements

- Cost

7. What are the common defects that can occur during panel lamination?

- Bubbles

- Wrinkles

- Delamination

- Splitting

8. How can you prevent defects from occurring during panel lamination?

- Use the correct adhesive for the application.

- Apply the adhesive evenly to the substrate.

- Laminate the panels under the correct pressure and temperature.

- Allow the panels to cure properly.

9. What are the quality control measures that you would implement in a panel lamination process?

- Inspect the substrate for any defects.

- Test the adhesive to ensure that it is the correct type and is being applied properly.

- Monitor the lamination process to ensure that the correct pressure and temperature are being used.

- Inspect the finished panels for any defects.

10. What are the emerging trends in panel lamination?

- The use of digital printing to create custom laminate designs.

- The development of new adhesives that are more environmentally friendly and have better performance characteristics.

- The use of automation to improve the efficiency and quality of the lamination process.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Panel Laminator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Panel Laminator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Panel Laminator is responsible for operating and maintaining machinery that laminates panels, typically used in the construction industry. They ensure that the lamination process is carried out efficiently and effectively, meeting the required specifications and quality standards.

1. Material Preparation

Gather and prepare raw materials, including panels, adhesives, and other components.

- Inspect panels for defects or damage.

- Apply adhesives or coatings to panels according to specified instructions.

2. Machine Operation

Operate laminating machinery, such as presses, rollers, or vacuum bags, to bond panels together.

- Set up and adjust machine according to panel specifications and process requirements.

- Monitor machine operation and make necessary adjustments to ensure proper bonding.

3. Quality Control

Inspect laminated panels for defects or imperfections.

- Use measuring tools and gauges to verify panel dimensions and adherence to specifications.

- Identify and resolve any quality issues promptly.

4. Equipment Maintenance

Perform basic maintenance and cleaning of laminating equipment.

- Lubricate moving parts and replace worn components.

- Maintain a clean and organized work area.

Interview Tips

Preparing for a Panel Laminator interview requires understanding the job responsibilities and demonstrating your skills and experience. Here are some tips to help you ace the interview:

1. Research the Company and Position

Learn about the company’s history, values, and the specific requirements of the Panel Laminator position. This information will help you tailor your answers and show that you’ve taken the time to understand the role.

- Visit the company’s website and social media pages.

- Read industry publications and articles to stay up-to-date on current trends and technologies.

2. Practice Common Interview Questions

Prepare answers to common interview questions related to your skills, experience, and motivation. This will help you articulate your qualifications clearly and confidently.

- Describe your experience operating and maintaining laminating machinery.

- Explain your understanding of the lamination process and quality control procedures.

- Provide examples of how you have resolved quality issues or improved efficiency in previous roles.

3. Showcase Relevant Skills and Experience

Highlight your technical skills, problem-solving abilities, and attention to detail. Provide specific examples from your past experience that demonstrate your proficiency in these areas.

- Quantify your accomplishments whenever possible.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

4. Prepare Questions for the Interviewer

Asking thoughtful questions shows that you’re engaged and interested in the position. It also gives you an opportunity to learn more about the company and the role.

- Inquire about the company’s growth plans and the importance of the Panel Laminator position within the organization.

- Ask about opportunities for professional development and advancement.

5. Dress Professionally and Arrive on Time

First impressions matter, so dress professionally and arrive on time for your interview. This demonstrates respect for the interviewer and the company.

- Choose clothing that is clean and pressed.

- If possible, visit the interview location in advance to avoid any unexpected delays.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Panel Laminator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!