Are you gearing up for an interview for a Pick-Pulling Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Pick-Pulling Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

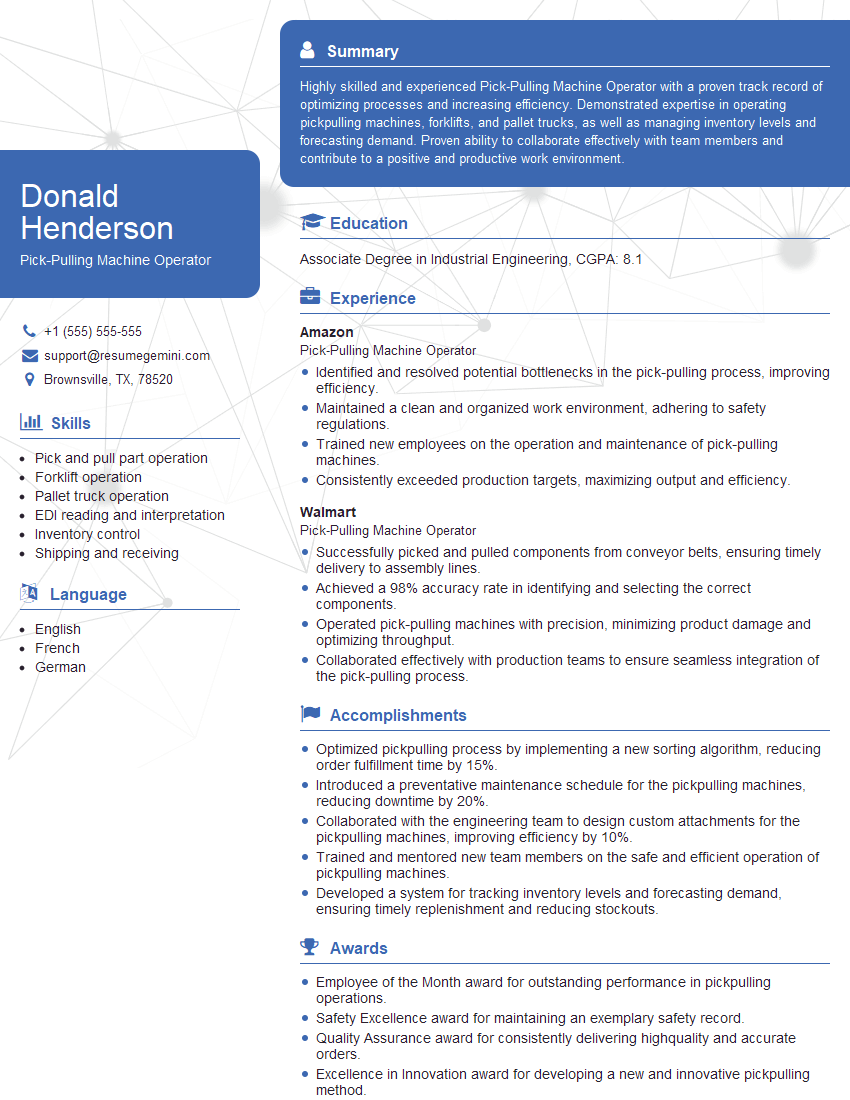

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pick-Pulling Machine Operator

1. Describe the process of setting up a pick-pulling machine.

The setup process involves several steps, including:

- Mounting the machine on a stable surface and securing it.

- Connecting the power source and ensuring proper electrical connections.

- Installing the vacuum cups or other gripping devices on the machine’s arms.

- Calibrating the machine’s sensors and adjusting the vacuum level based on the weight and dimensions of the items being picked.

- Programming the pick-pulling sequence, including the pick-up and drop-off points, speeds, and any other necessary parameters.

2. How do you ensure that the pick-pulling machine operates safely and efficiently?

Regular Maintenance

- Conducting regular inspections to check for any loose connections, damaged components, or worn-out parts.

- Performing routine cleaning and lubrication to ensure smooth operation and prevent breakdowns.

Safe Operation

- Wearing appropriate personal protective equipment (PPE), such as gloves and safety glasses.

- Ensuring that the work area is clear of obstacles and that the machine is operated on a level surface.

- Following operating procedures and avoiding overloading the machine with weights beyond its capacity.

3. Describe the different types of pick-pulling machines and their applications.

- Cartesian pick-pulling machines: Move in a linear (X, Y, Z) direction, suitable for simple pick-and-place operations.

- Scara pick-pulling machines: Offer greater flexibility, allowing for rotational movement, ideal for complex assembly tasks.

- Delta pick-pulling machines: Provide high speed and accuracy, often used in electronics manufacturing.

- Parallel pick-pulling machines: Designed for high-volume applications, with multiple arms operating simultaneously.

4. How do you troubleshoot common issues encountered with pick-pulling machines?

Troubleshooting involves identifying and resolving issues that may arise during operation:

- Vacuum loss: Checking vacuum lines and connections, replacing worn-out seals.

- Gripper malfunction: Inspecting and cleaning grippers, adjusting grip force or replacing damaged components.

- Programming errors: Verifying the pick-pulling sequence and ensuring that parameters are set correctly.

- Electrical faults: Checking electrical connections, fuses, and wiring for any defects.

5. How do you optimize the performance of a pick-pulling machine?

- Regular calibration: Ensuring accurate movements and pick-up points.

- Fine-tuning parameters: Adjusting vacuum levels, speeds, and acceleration to maximize efficiency.

- Preventive maintenance: Implementing a regular maintenance schedule to minimize downtime.

- Operator training: Providing training to operators to ensure proper operation and handling.

6. Explain the safety precautions that you observe when working with pick-pulling machines.

- PPE: Always wearing appropriate personal protective equipment, such as gloves, safety glasses, and closed-toe shoes.

- Work area: Ensuring that the work area is clear of obstacles and free from tripping hazards.

- Machine operation: Operating the machine within its specified capacity and following established procedures.

- Emergency stop: Being familiar with the location of the emergency stop button and knowing when to use it.

7. How do you handle delicate or fragile items with a pick-pulling machine?

- Proper gripping devices: Using specialized vacuum cups or grippers designed for handling delicate items.

- Reduced vacuum pressure: Adjusting the vacuum level to avoid damaging the items.

- Gentle handling: Moving the machine slowly and carefully, avoiding sudden jerks or jolts.

- Soft landing: Ensuring that items are placed on a soft surface or in a controlled manner to prevent breakage.

8. How do you program a pick-pulling machine to perform complex sequences?

Programming involves defining the pick-up and drop-off points, speeds, and any other necessary parameters:

- Programming language: Using a specific programming language or software designed for pick-pulling machines.

- Sequence definition: Creating a sequence of commands that specify the desired operations.

- Testing and refinement: Running test cycles and making adjustments to optimize the sequence.

9. How do you maintain accurate and consistent performance of a pick-pulling machine?

- Regular calibration: Performing regular calibration to ensure precise movements and alignment.

- Wear and tear monitoring: Inspecting components for signs of wear and replacing them as needed.

- Software updates: Installing software updates to improve functionality and reliability.

- Operator training: Providing training to operators on proper handling and maintenance techniques.

10. How do you stay up-to-date with the latest advancements in pick-pulling technology?

- Industry events: Attending industry conferences and exhibitions to learn about new products and innovations.

- Online resources: Reading industry publications, visiting manufacturers’ websites, and participating in online forums.

- Networking: Connecting with other professionals in the field to share knowledge and insights.

- Training and certifications: Pursuing professional development opportunities to enhance skills and stay current with industry standards.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pick-Pulling Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pick-Pulling Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The role of the Pick-Pulling Machine Operator is important in maintaining efficient operations in a warehouse or manufacturing setting.

1. Machine Operation

Primarily, the Operator is accountable for the proper functioning of the pick-pulling machine.

- Analyzing orders and identifying the appropriate pick paths

- Operating the machine to retrieve goods from designated storage locations

2. Inventory Management

The Operator plays a crucial role in maintaining inventory accuracy.

- Scanning and verifying goods retrieved from storage

- Ensuring that picked items match the order specifications

3. Quality Assurance

The Operator is responsible for ensuring that picked goods meet quality standards.

- Inspecting goods for any defects or damages

- Rejecting and reporting defective or non-compliant items

4. Team Collaboration

The Operator works closely with other teams to ensure seamless operations.

- Coordinating with warehouse personnel to locate and retrieve goods

- Communicating with shipping and receiving teams to facilitate product movement

Interview Tips

Preparing thoroughly for your interview is essential to making a positive impression.

1. Research the Company and Role

Gather information about the company’s industry, values, and specific requirements for the Pick-Pulling Machine Operator position.

- Visit the company’s website and social media pages

- Read industry news and articles to stay updated on relevant trends

2. Practice Your Answers

Reflect on common interview questions and prepare concise, well-structured responses that highlight your skills and experience.

- Use the STAR method (Situation, Task, Action, Result) to share specific examples that demonstrate your capabilities

- Consider preparing answers to questions about your technical skills, problem-solving abilities, and teamwork experience

3. Dress Professionally and Arrive Punctually

First impressions matter, so dress appropriately and arrive on time for your interview. This demonstrates respect for the interviewer and the company.

- Choose business attire that is clean, pressed, and fits well

- Plan to arrive at the interview location 15-20 minutes early to allow for any unexpected delays

4. Be Confident and Enthusiastic

Project a positive and confident demeanor throughout your interview. Show enthusiasm for the role and the company.

- Make eye contact, smile, and speak clearly

- Be prepared to share why you are interested in the company and the position

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Pick-Pulling Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.