Are you gearing up for an interview for a Plastics Fabricator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Plastics Fabricator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

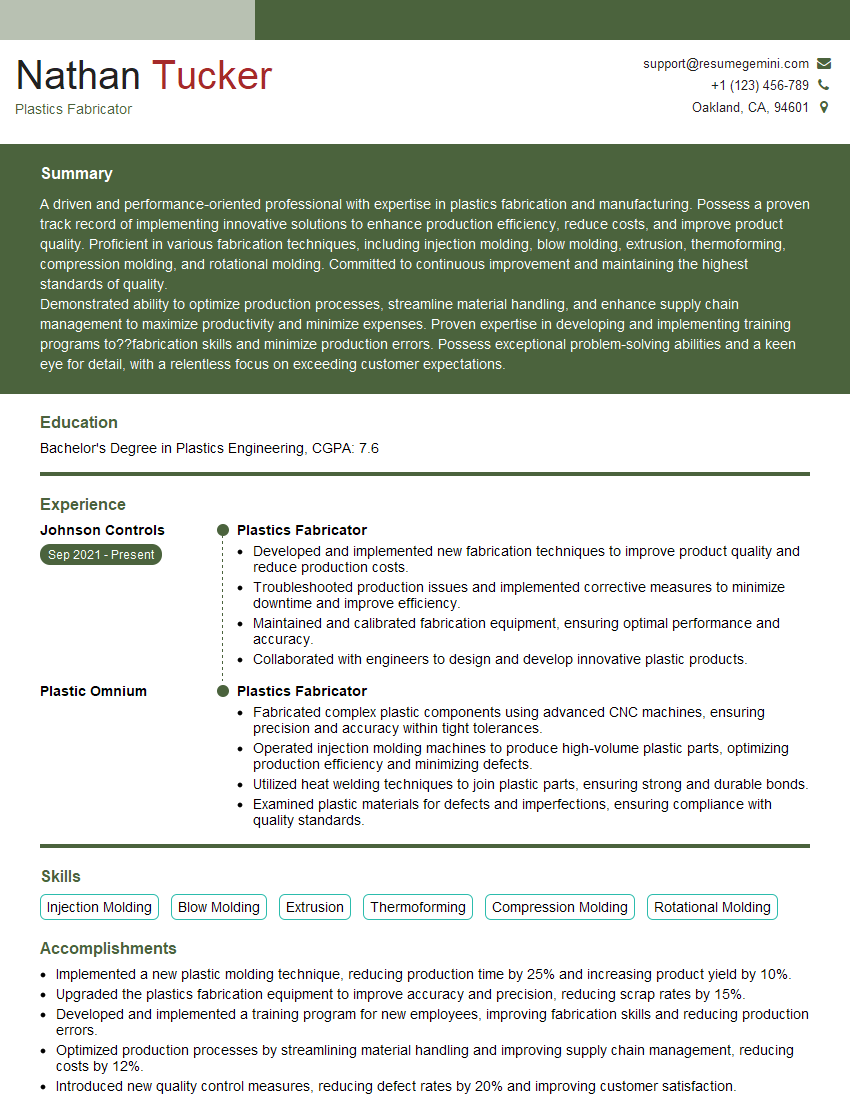

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plastics Fabricator

1. Describe the various types of plastics fabrication processes you have experience with?

In my previous role, I have gained extensive experience in a range of plastics fabrication processes, including:

- Injection Molding: Expertise in operating injection molding machines, setting process parameters, and troubleshooting common issues.

- Extrusion: Proficient in configuring extrusion lines, selecting appropriate dies, and monitoring production to ensure quality.

- Thermoforming: Skilled in forming plastic sheets into complex shapes using vacuum or pressure forming techniques.

- CNC Machining: Experience in programming and operating CNC machines to fabricate precision plastic components.

2. Explain the key factors to consider when selecting the appropriate plastic material for a given application?

When selecting the appropriate plastic material for a given application, I consider several key factors:

Chemical Resistance

- The intended use of the product and its exposure to potential chemicals, such as acids, bases, or solvents.

Mechanical Properties

- The required strength, flexibility, and durability for the specific application and environment.

Thermal Properties

- The maximum and minimum temperatures that the plastic will experience and its ability to withstand thermal expansion and contraction.

Cost and Availability

- The budget constraints and the lead time required for obtaining the material.

3. What techniques do you use to ensure the accuracy and precision of fabricated plastic parts?

To ensure the accuracy and precision of fabricated plastic parts, I employ the following techniques:

- Dimensional Inspection: Using calipers, micrometers, and coordinate measuring machines to verify dimensions and tolerances.

- Visual Inspection: Conducting thorough visual examinations to identify any surface defects, blemishes, or deviations from specifications.

- Non-Destructive Testing: Employing techniques such as ultrasonic testing or X-ray analysis to detect internal flaws or voids.

- Calibration and Maintenance: Regularly calibrating and maintaining all measuring and fabrication equipment to ensure accuracy and repeatability.

4. How do you handle complex fabrication projects involving multiple components and tight tolerances?

When handling complex fabrication projects with multiple components and tight tolerances, I follow a systematic approach:

- Project Planning: Breaking down the project into manageable tasks, identifying critical dimensions, and establishing clear quality standards.

- Component Fabrication: Fabricating each component with precision using appropriate techniques and verifying its dimensions meticulously.

- Assembly: Carefully assembling the components according to the design specifications, ensuring proper alignment and fit.

- Inspection and Testing: Conducting rigorous inspections and tests to ensure that the assembled product meets the required tolerances and performance criteria.

5. Describe your experience with using computer-aided design (CAD) software in plastics fabrication?

I am proficient in using CAD software such as SolidWorks and AutoCAD for plastics fabrication. My expertise includes:

- 3D Modeling: Creating accurate 3D models of plastic parts and assemblies, ensuring proper dimensions and geometry.

- 2D Drafting: Generating detailed 2D technical drawings for manufacturing and assembly purposes, following industry standards.

- Simulation and Analysis: Utilizing CAD software to simulate manufacturing processes, analyze stresses and deformations, and optimize designs.

6. How do you stay updated with the latest advancements and best practices in plastics fabrication?

To stay abreast of the latest advancements and best practices in plastics fabrication, I engage in the following activities:

- Industry Events: Attending trade shows, conferences, and workshops to network with experts and learn about new technologies and materials.

- Online Resources: Regularly accessing industry websites, technical journals, and online forums to gather information on emerging trends and developments.

- Training and Certifications: Pursuing additional training and certifications to enhance my knowledge and skills in specific areas of plastics fabrication.

7. What safety precautions do you follow when working in a plastics fabrication environment?

I adhere to strict safety precautions when working in a plastics fabrication environment to protect myself and others:

- Personal Protective Equipment: Always wearing appropriate PPE, including safety glasses, gloves, earplugs, and a respirator when required.

- Machine Safety: Ensuring that all machines are properly guarded and operated according to safety protocols.

- Chemical Handling: Handling chemicals, such as solvents and adhesives, with care, following proper storage and disposal guidelines.

- Fire Safety: Being aware of potential fire hazards and knowing how to use fire extinguishers and evacuation procedures.

8. How do you approach problem-solving and troubleshooting during the plastics fabrication process?

When faced with problems or issues during the plastics fabrication process, I take a systematic approach to problem-solving and troubleshooting:

- Identify and Analyze: Identifying the root cause of the problem through careful observation and analysis.

- Research and Consult: Consulting with colleagues, researching online resources, or seeking expert advice to gather potential solutions.

- Test and Evaluate: Implementing and testing different solutions to determine the most effective approach.

- Document and Implement: Documenting the solution and sharing it with the team to prevent recurrence and improve overall processes.

9. Tell me about your experience with optimizing plastics fabrication processes to improve efficiency and reduce costs?

In my previous role, I successfully implemented several initiatives to optimize plastics fabrication processes and achieve significant efficiency and cost improvements:

- Process Analysis: Conducted thorough process analysis to identify bottlenecks and inefficiencies.

- Equipment Upgrading: Researched and invested in new equipment and technologies to streamline operations.

- Automation: Implemented automation solutions to reduce manual labor and improve production speed.

- Material Management: Optimized material usage, reduced waste, and improved inventory control.

10. Describe a situation where you had to work effectively as part of a team to complete a complex plastics fabrication project?

In a previous project, I collaborated effectively within a team to complete a complex plastics fabrication project:

- Role Definition: We clearly defined each team member’s roles and responsibilities.

- Communication and Coordination: Established effective communication channels and coordination mechanisms.

- Task Allocation: Divided tasks efficiently based on individual strengths and expertise.

- Regular Progress Updates: Conducted regular team meetings to track progress, identify challenges, and adjust plans.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plastics Fabricator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plastics Fabricator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A plastics fabricator is tasked with using highly specialized machinery and equipment to shape, finish, and assemble plastic materials into products and components according to specifications.

1. Raw Material Handling

Their responsibilities may be primarily focused on one specialized process but will often include: Handling raw plastic materials such as sheets, rods, tubes, and granules.

2. Cutting and Shaping

Using precision tools and machinery including saws, drills, lathes, and grinders to cut, shape, and form plastic materials into desired configurations.

3. Forming and Assembly

Applying heat, pressure, and adhesives to bond, weld, and assemble plastic components into finished products or subassemblies.

4. Finishing and Inspection

Performing finishing operations such as sanding, polishing, and painting to enhance the appearance and functionality of fabricated products. They also inspect finished products to ensure they meet specifications and quality standards.

Interview Tips

Preparing for a Plastics Fabricator job interview can be essential in making a positive impression on potential employers and increasing your chances of success. Here are some tips to help you ace your interview.

1. Research the Company and Industry

Take the time to learn about the company you’re applying to, their products or services, and the plastics fabrication industry as a whole. This will demonstrate your interest and enthusiasm for the position.

2. Highlight Your Technical Skills

Emphasize your proficiency in the specific techniques and equipment used in plastics fabrication, such as cutting, forming, bonding, and finishing. Provide examples of projects you’ve worked on that showcase your abilities.

3. Showcase Your Attention to Detail

Plastics fabrication requires a high level of precision and attention to detail. Highlight your ability to follow instructions accurately, produce high-quality work, and meet tight tolerances.

4. Prepare for Common Interview Questions

Research common interview questions for plastics fabricators. Practice answering them in a clear and concise manner, providing specific examples to support your responses.

5. Be Enthusiastic and Professional

Demonstrate your passion for plastics fabrication and your commitment to delivering exceptional results. Maintain a positive attitude and dress appropriately for the interview.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Plastics Fabricator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Plastics Fabricator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.