Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Printed Circuit Board Photoresist Laminator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

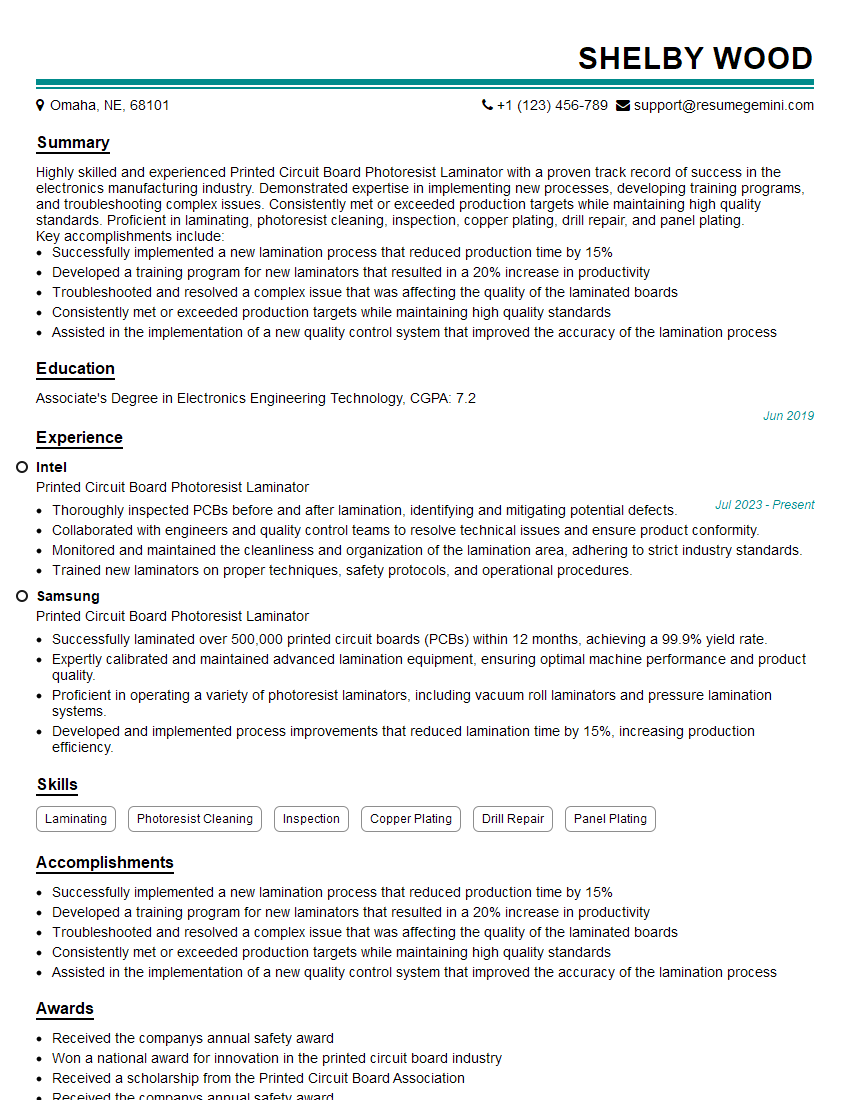

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Printed Circuit Board Photoresist Laminator

1. Explain the process of photoresist lamination in PCB manufacturing?

- Clean the copper surface of the PCB to remove any contaminants.

- Apply a thin layer of photoresist to the copper surface. This can be done using a spin coater or a dip coater.

- Expose the photoresist to ultraviolet light through a photomask. This will create a pattern of exposed and unexposed photoresist on the board.

- Develop the photoresist using a developer solution. This will remove the unexposed photoresist, leaving only the exposed photoresist pattern on the board.

- Etch the exposed copper using an etching solution. This will remove the copper from the areas that are not protected by the photoresist.

- Strip the photoresist from the board using a stripper solution. This will leave the finished PCB with the desired copper pattern.

2. What are the different types of photoresists used in PCB manufacturing?

- Positive photoresist: This type of photoresist is exposed to ultraviolet light and the areas that are exposed to light become hardened. The unexposed areas are washed away during development.

- Negative photoresist: This type of photoresist is exposed to ultraviolet light and the areas that are not exposed to light become hardened. The exposed areas are washed away during development.

3. What are the factors that affect the quality of photoresist lamination?

- The cleanliness of the copper surface

- The thickness of the photoresist

- The exposure time

- The development time

- The etching time

- The stripping time

4. What are the common problems that can occur during photoresist lamination?

- Bubbles in the photoresist

- Overexposure or underexposure of the photoresist

- Incomplete development of the photoresist

- Etching of the copper under the photoresist

- Stripping of the photoresist from the board

5. How do you troubleshoot problems that occur during photoresist lamination?

- Check the cleanliness of the copper surface.

- Check the thickness of the photoresist.

- Check the exposure time.

- Check the development time.

- Check the etching time.

- Check the stripping time.

6. What are the safety precautions that must be taken when working with photoresist?

- Wear gloves and a lab coat when handling photoresist.

- Use a fume hood when working with photoresist chemicals.

- Dispose of photoresist chemicals properly.

- Avoid skin contact with photoresist.

- Avoid eye contact with photoresist.

7. What are the latest trends in photoresist lamination?

- The use of laser direct imaging (LDI) to expose photoresist.

- The use of plasma etching to etch copper.

- The use of photoresistless copper plating.

8. Describe the different types of laminators used in PCB manufacturing?

- Vacuum laminators

- Pressure laminators

- Thermal laminators

9. How do you maintain a laminator?

- Clean the laminator regularly.

- Inspect the laminator for wear and tear.

- Calibrate the laminator regularly.

- Follow the manufacturer’s instructions for maintenance.

10. What are the safety precautions that must be taken when working with a laminator?

- Wear gloves and a lab coat when operating a laminator.

- Use a fume hood when working with laminating chemicals.

- Dispose of laminating chemicals properly.

- Avoid skin contact with laminating chemicals.

- Avoid eye contact with laminating chemicals.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Printed Circuit Board Photoresist Laminator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Printed Circuit Board Photoresist Laminator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Printed Circuit Board Photoresist Laminator is a key member of the manufacturing team, responsible for operating and maintaining the laminating machines that produce printed circuit boards (PCBs). PCBs are used in a wide range of electronic devices, including computers, smartphones, and cars.

1. Operating and Maintaining Laminating Machines

The most important responsibility of a Photoresist Laminator is to operate and maintain the laminating machines that produce PCBs. These machines use heat and pressure to bond layers of copper foil and fiberglass to create a finished PCB. Photoresist Laminators must be able to operate these machines safely and efficiently, and they must be able to troubleshoot and resolve any problems that may arise.

- Set up and operate laminating machines to bond layers of copper foil and fiberglass to create PCBs

- Monitor the laminating process to ensure that the temperature and pressure are correct

- Troubleshoot and resolve any problems that may arise during the laminating process

2. Quality Control

Photoresist Laminators are also responsible for ensuring that the PCBs they produce meet the required quality standards. This involves inspecting the PCBs for defects, such as scratches, dents, or misalignment. Photoresist Laminators must be able to identify defects quickly and accurately, and they must be able to take corrective action to prevent future defects.

- Inspect PCBs for defects, such as scratches, dents, or misalignment

- Identify defects quickly and accurately

- Take corrective action to prevent future defects

3. Safety

Safety is a top priority in the PCB manufacturing process. Photoresist Laminators must be able to follow safety procedures and wear appropriate safety gear at all times. They must also be aware of the potential hazards of the materials they are working with, such as chemicals and solvents.

- Follow safety procedures and wear appropriate safety gear at all times

- Be aware of the potential hazards of the materials they are working with, such as chemicals and solvents

4. Teamwork

Photoresist Laminators are part of a team that includes engineers, technicians, and other production staff. They must be able to work well with others and communicate effectively to ensure that the PCB manufacturing process runs smoothly.

- Work well with others and communicate effectively

- Be a team player and contribute to the overall success of the PCB manufacturing process

Interview Tips

Preparing for an interview for a Printed Circuit Board Photoresist Laminator position can be daunting, but with the right preparation, you can increase your chances of success. Here are a few tips to help you ace your interview:

1. Research the Company and the Position

Before you go to your interview, take some time to research the company and the position you’re applying for. This will help you understand the company’s culture, values, and goals, as well as the specific requirements of the position. You can find this information on the company’s website, social media pages, and Glassdoor.

- Visit the company’s website and social media pages

- Read reviews on Glassdoor and other job boards

- Talk to people in your network who work at the company

2. Practice Your Answers to Common Interview Questions

There are some common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It’s a good idea to practice your answers to these questions in advance so that you can deliver them confidently and concisely. You can also prepare for specific questions about your experience and qualifications by reviewing the job description.

- Practice your answers to common interview questions

- Review the job description and prepare for specific questions about your experience and qualifications

- Use the STAR method to answer interview questions

3. Dress Professionally and Arrive on Time

First impressions matter, so it’s important to dress professionally for your interview. This means wearing a suit or dress pants and a button-down shirt or blouse. You should also arrive on time for your interview. Punctuality shows that you’re respectful of the interviewer’s time.

- Dress professionally in a suit or dress pants and a button-down shirt or blouse

- Arrive on time for your interview

- Be polite and respectful to the interviewer

4. Be Enthusiastic and Positive

Interviewers want to hire people who are enthusiastic and positive about their work. Show the interviewer that you’re excited about the opportunity to work at the company and that you’re confident in your abilities. You can do this by smiling, making eye contact, and speaking clearly and confidently.

- Be enthusiastic and positive about your work

- Smile, make eye contact, and speak clearly and confidently

- Show the interviewer that you’re excited about the opportunity to work at the company

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Printed Circuit Board Photoresist Laminator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.