Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Putty Tinter Maker interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Putty Tinter Maker so you can tailor your answers to impress potential employers.

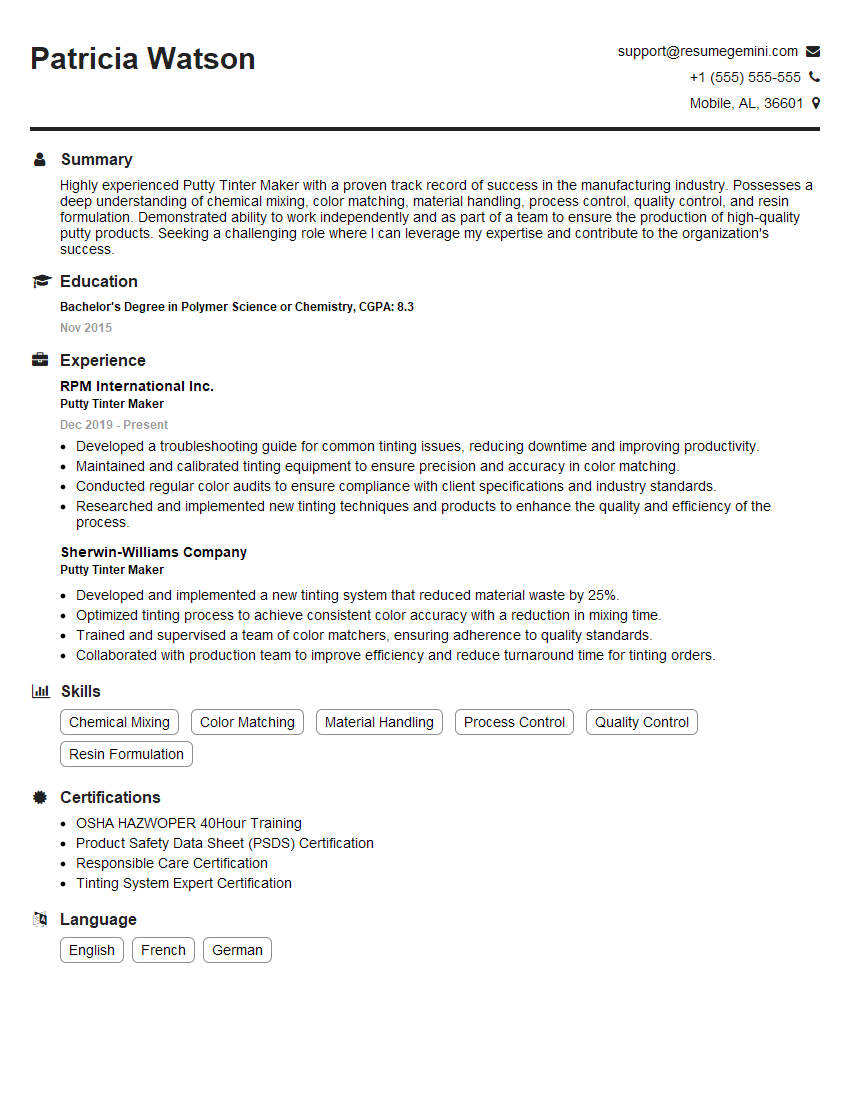

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Putty Tinter Maker

1. What are the key factors to consider when selecting raw materials for putty tinting?

- Colorfastness and light resistance: To ensure color accuracy and prevent fading over time

- Opacity andhiding power: To effectively cover the underlying surface and provide the desired color depth

- Rheology and flow properties: To achieve the desired application and leveling characteristics

- Viscosity and workability: To facilitate ease of mixing, application, and removal of excess material

- Compatibility and stability: To ensure compatibility with other paint components and prevent color shifts or reactions

2. Describe the different types of putty tinting machines and their respective advantages and disadvantages.

Blade-type machines

- Advantages: Fast, efficient, and produce high-quality tints

- Disadvantages: Can generate heat and require regular maintenance

Roller-type machines

- Advantages: More gentle on materials, reduce heat generation

- Disadvantages: Slower and may require multiple passes for consistent mixing

Centrifugal-type machines

- Advantages: Compact, portable, and suitable for small-scale applications

- Disadvantages: May produce less consistent results compared to other types

3. How do you manage color accuracy and consistency in putty tinting?

- Utilizing high-quality, calibrated spectrophotometers for color measurement

- Adhering to standardized mixing procedures and formulas

- Maintaining consistent raw material quality and storage conditions

- Regularly calibrating equipment and performing quality control checks

- Implementing color management software to track and manage color data

4. Explain the role of dispersants in putty tinting and discuss the factors to consider when selecting them.

- Purpose: To prevent agglomeration and sedimentation of pigments

- Factors to consider: Compatibility with putty base, pigment type, and desired rheological properties

- Types of dispersants: Anionic, cationic, non-ionic, polymeric

5. How do you troubleshoot common defects in putty tinting, such as color shifts, poor adhesion, and cracking?

- Incorrect colorant selection or dosage

- Exposure to UV light or extreme temperatures

- Insufficient surface preparation

- Incompatibility between putty and underlying surface

- Excessive putty thickness

- Rapid drying or shrinkage

Color shifts

Poor adhesion

Cracking

6. Describe the safety measures you follow when working with putty tinting materials.

- Wearing appropriate personal protective equipment (PPE) such as gloves, masks, and safety glasses

- Ensuring proper ventilation and avoiding inhalation of fumes

- Storing and handling chemicals safely according to manufacturer’s instructions

- Following proper disposal procedures for waste materials

- Undergoing regular safety training and staying up-to-date on industry regulations

7. What are the key differences between water-based and solvent-based putty tinting systems?

- Advantages: Environmentally friendly, low VOC emissions, easier cleanup

- Disadvantages: May have longer drying times, less durable than solvent-based systems

- Advantages: Excellent adhesion, faster drying times, highly durable

- Disadvantages: Higher VOC emissions, more hazardous materials, require special disposal methods

Water-based

Solvent-based

8. How do you stay updated on the latest advancements in putty tinting technology and industry best practices?

- Attending industry conferences and workshops

- Reading technical journals and publications

- Networking with other professionals in the field

- Undertaking manufacturer-provided training and certification programs

- Staying informed through online resources and industry news

9. Discuss the importance of quality control in putty tinting and describe the steps involved.

- Ensures consistent product quality and customer satisfaction

- Includes: Raw material inspection, color matching verification, performance testing, and documentation

- Regular audits and monitoring to identify and address potential issues

10. How do you manage inventory and ensure optimal usage of putty tinting materials?

- Implementing inventory management systems to track stock levels and consumption

- Forecasting demand and planning production accordingly

- Optimizing mixing ratios and minimizing waste

- Establishing shelf-life management policies to prevent spoilage and ensure material freshness

- Collaborating with suppliers for timely and reliable delivery

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Putty Tinter Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Putty Tinter Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities: Putty Tinter Maker

Putty Tinter Makers play a crucial role in the manufacturing of paints and coatings by meticulously matching colors and creating custom shades. Their key responsibilities include:

1. Color Matching and Formulation

Analyze customer specifications and precisely match colors using various techniques, including sample matching, spectrophotometry, and visual assessment.

2. Pigment Dispersion and Grinding

Disperse pigments effectively to achieve optimal color and performance. Grind pigments to the required fineness and ensure uniform particle size distribution.

3. Testing and Quality Control

Perform quality control checks to ensure colors meet specifications and standards. Test tints for viscosity, opacity, shade, and other properties.

4. Equipment Maintenance and Calibration

Maintain equipment used in color matching and production, including spectrophotometers, mixers, and grinders. Calibrate equipment regularly to ensure accuracy and reliability.

5. Safety Compliance

Adhere to all safety regulations and guidelines. Handle and dispose of chemicals and materials responsibly.

Interview Tips for Putty Tinter Makers

Preparing thoroughly for an interview as a Putty Tinter Maker can significantly increase your chances of success. Consider the following tips:

1. Research the Company and Industry

Gain insights into the company’s culture, products, and market position. Understand the latest trends and developments in the paint and coatings industry.

2. Highlight Your Color Matching and Formulation Skills

Emphasize your expertise in color matching techniques and your ability to create custom shades. Quantify your achievements and provide specific examples of successful color formulations.

3. Demonstrate Your Knowledge of Pigments

Discuss your understanding of different pigments, their properties, and their impact on color. Explain how you optimize pigment dispersion and grinding to achieve desired results.

4. Showcase Your Quality Control Expertise

Highlight your proficiency in testing tinted paints and coatings. Explain your knowledge of quality control standards and how you ensure consistency in production.

5. Prepare for Technical Questions

Expect questions about spectrophotometry, color theory, and paint chemistry. Prepare answers that demonstrate your technical competence and problem-solving skills.

6. Express Your Passion for Color

Convey your genuine interest in color and your commitment to delivering exceptional results. Explain how you derive satisfaction from creating visually appealing and high-quality paints and coatings.

7. Practice Your Presentation Skills

Rehearse your answers to common interview questions. Speak clearly and confidently, and use specific examples to support your claims.

8. Ask Thoughtful Questions

Prepare questions that show your engagement in the interview and your interest in the company. Ask about the company’s growth plans, sustainability initiatives, or any specific projects that align with your skills.

9. Dress Professionally and Punctually

First impressions matter. Dress appropriately and arrive for your interview on time. Maintain a professional demeanor throughout the process.

10. Follow Up Gracefully

Send a thank-you note to the interviewer within 24 hours of the interview. Express your appreciation for their time and reiterate your interest in the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Putty Tinter Maker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!