Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Rendering Equipment Tender position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

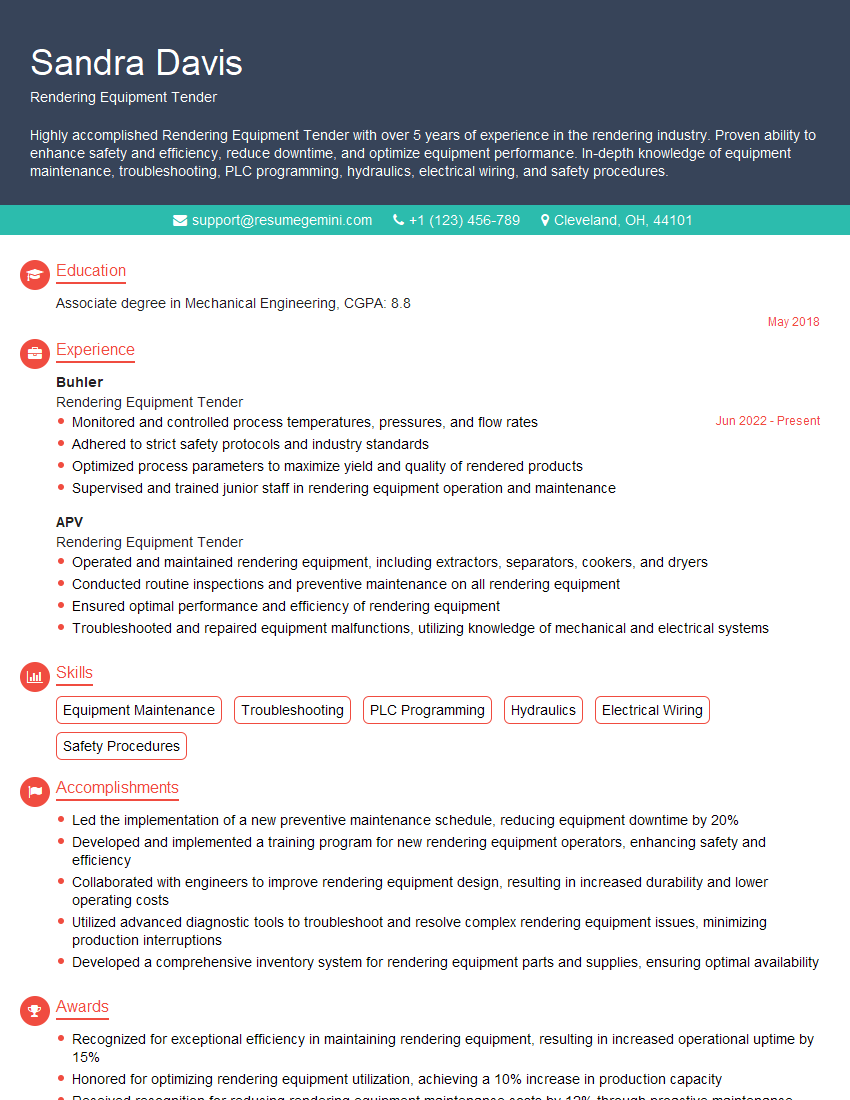

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rendering Equipment Tender

1. Describe the key components and their functions in a rendering equipment system.

A rendering equipment system consists of several key components, each playing a specific role in the rendering process. Here are the main components and their functions:

- Cooker: The cooker is responsible for heating and agitating the raw materials (animal tissues) to extract fat and other valuable components. It can be a batch cooker or a continuous cooker, depending on the system’s design.

- Separator: The separator is used to separate the rendered fat from the other components, such as solids (cracklings) and water. It can be a decanter or a centrifuge, depending on the desired separation efficiency.

- Clarifier: The clarifier further purifies the rendered fat by removing impurities, such as suspended solids and moisture. It can be a filtration system or a settling tank.

- Evaporator: The evaporator is used to remove moisture from the rendered fat, resulting in a higher fat content. It can be a single-effect or multiple-effect evaporator.

- Deodorizer: The deodorizer removes undesirable odors from the rendered fat by stripping volatile compounds. It involves heating the fat under vacuum conditions.

2. Explain the different types of rendering systems and their applications.

Batch Rendering Systems

- Suitable for small-scale operations

- Process raw materials in batches

- Lower production capacity compared to continuous systems

Continuous Rendering Systems

- Designed for large-scale operations

- Process raw materials continuously

- Higher production capacity and efficiency

Dry Rendering Systems

- Remove moisture from raw materials before rendering

- Produce high-quality fat with low moisture content

- Suitable for rendering animal byproducts

Wet Rendering Systems

- Render raw materials with their natural moisture content

- Produce a lower-quality fat with higher moisture content

- Commonly used for rendering poultry and fish

3. Describe the factors that affect the quality of rendered fat.

- Raw material quality: The quality of the raw materials (animal tissues) used for rendering significantly impacts the final fat quality.

- Rendering conditions: Temperature, pressure, and agitation during the rendering process can affect the fat’s yield, composition, and color.

- Post-rendering processing: Proper clarification, evaporation, and deodorization steps ensure the removal of impurities, moisture, and undesirable odors.

- Storage conditions: Fat quality can deteriorate over time due to oxidation, hydrolysis, and contamination. Proper storage conditions (temperature, light, and packaging) are crucial.

4. Explain the maintenance procedures and troubleshooting tips for rendering equipment.

Maintenance Procedures:

- Regular cleaning and inspection of all equipment components

- Lubrication and adjustment of moving parts

- Replacement of worn or damaged parts as needed

- Monitoring of temperature, pressure, and other process parameters

Troubleshooting Tips:

- Low fat yield: Check for proper temperature and agitation in the cooker, ensure efficient separation, and minimize moisture loss.

- High moisture content in rendered fat: Inspect the evaporator for proper operation and ensure adequate evaporation time.

- Undesirable odors: Check the deodorizer for proper operation and vacuum conditions, and ensure the fat is free of contaminants.

- Clogged or blocked equipment: Inspect for any obstructions in pipes, pumps, or filters and clear them promptly.

5. Describe the safety precautions to be observed when operating rendering equipment.

- Wear appropriate personal protective equipment (PPE), including gloves, goggles, and protective clothing.

- Follow proper lockout/tagout procedures before performing any maintenance or repairs.

- Be aware of potential hazards, such as hot surfaces, moving machinery, and chemical spills.

- Maintain a clean and organized work area to prevent accidents.

- Receive proper training and certification for operating rendering equipment safely.

6. What are the key performance indicators (KPIs) used to measure the efficiency of a rendering operation?

- Fat yield: The percentage of rendered fat recovered from the raw materials.

- Moisture content: The amount of moisture present in the rendered fat.

- Free fatty acid (FFA) content: Indicates the degree of fat breakdown or oxidation.

- Production capacity: The amount of fat produced per unit of time.

- Energy consumption: The amount of energy required to operate the rendering system.

7. Explain the environmental regulations and industry standards that apply to rendering operations.

Rendering operations must comply with various environmental regulations and industry standards to ensure responsible waste management and minimize environmental impact. Key regulations and standards include:

- Clean Air Act and Clean Water Act (US)

- Resource Conservation and Recovery Act (RCRA)

- National Emission Standards for Hazardous Air Pollutants (NESHAP)

- Best Available Control Technology (BACT)

- National Renderers Association (NRA) standards

8. What are the latest technological advancements in rendering equipment and processing techniques?

The rendering industry is constantly evolving with technological advancements. Some of the latest innovations include:

- Automated control systems: Monitor and optimize process parameters for improved efficiency and quality control.

- Advanced separation technologies: Enhance fat yield and reduce impurities.

- Energy-efficient evaporators: Utilize heat recovery and reduce energy consumption.

- Odor control systems: Mitigate odors and improve environmental performance.

- Continuous dry rendering systems: Improve fat quality and reduce moisture content.

9. Describe the role of sustainability in modern rendering operations.

Sustainability is becoming increasingly important in the rendering industry. Key aspects of sustainable rendering practices include:

- Raw material sourcing: Ensuring responsible sourcing and ethical treatment of animals.

- Waste management: Minimizing environmental impact by properly managing solid and liquid waste.

- Energy efficiency: Optimizing energy consumption to reduce carbon footprint.

- Byproduct utilization: Finding valuable uses for byproducts, such as cracklings and meat meal.

- Community engagement: Building positive relationships with local communities and addressing their concerns.

10. What are the key qualities and skills required to be a successful Rendering Equipment Tender?

- Technical knowledge: In-depth understanding of rendering equipment, processes, and technologies.

- Sales and negotiation skills: Ability to effectively communicate the benefits and value of rendering equipment to potential customers.

- Project management skills: Ability to manage the procurement, installation, and commissioning of rendering equipment.

- Customer service orientation: Strong commitment to providing excellent support and resolving customer issues.

- Industry knowledge: Understanding of the rendering industry, market trends, and regulatory requirements.

- Problem-solving skills: Ability to identify and resolve technical challenges and equipment issues.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rendering Equipment Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rendering Equipment Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Rendering Equipment Tenders are responsible for procuring and maintaining equipment used in the rendering process. Their duties include:

1. Procurement

Identify and evaluate suppliers for rendering equipment.

- Prepare and distribute tender documents.

- Evaluate and select bids based on price, quality, and delivery time.

2. Contract Management

Negotiate and execute contracts with selected suppliers.

- Monitor contract performance and ensure compliance.

- Resolve any issues that arise during contract execution.

3. Equipment Maintenance

Ensure that rendering equipment is maintained in good working condition.

- Schedule and oversee maintenance activities.

- Monitor equipment performance and identify potential problems.

- Work with maintenance technicians to repair and troubleshoot equipment.

4. Inventory Management

Maintain an inventory of rendering equipment.

- Track equipment usage and stock levels.

- Order and receive new equipment as needed.

- Dispose of surplus equipment.

Interview Tips

To ace an interview for a Rendering Equipment Tender position, candidates should:

1. Research the Company and Industry

Learn about the company’s business, products, and services.

- Research the rendering industry and its trends.

- Identify the company’s competitors and their strengths and weaknesses.

2. Prepare Answers to Common Interview Questions

Practice answering common interview questions, including:

- Tell me about your experience in procurement and contract management.

- How do you ensure that equipment is maintained in good working condition?

- What are your strengths and weaknesses as a Rendering Equipment Tender?

3. Demonstrate Technical Knowledge

Candidates should be familiar with the different types of rendering equipment and their maintenance requirements.

- Highlight any experience in working with vendors and contractors.

- Be prepared to discuss new trends in the rendering industry.

4. Show Enthusiasm and Commitment

Candidates should be passionate about the rendering industry and committed to the success of the company.

- Express your interest in the position and the company’s mission.

- Be prepared to share your ideas for improving the efficiency of the rendering process.

Next Step:

Now that you’re armed with the knowledge of Rendering Equipment Tender interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Rendering Equipment Tender positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini