Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Ribbon Cleaner position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

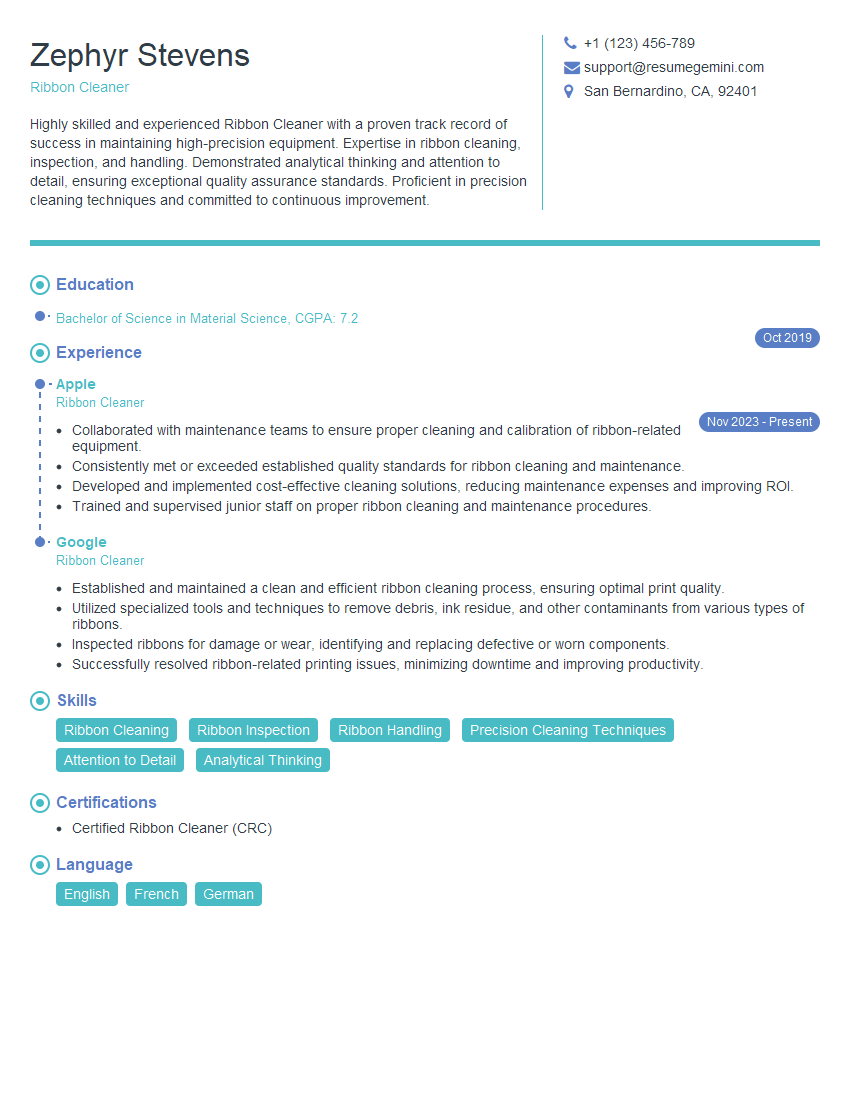

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ribbon Cleaner

1. Explain the process of cleaning a ribbon cartridge?

To clean a ribbon cartridge, I would:

- Unwind the used ribbon from the cartridge.

- Wipe down the cartridge base with a soft, lint-free cloth, dampened with alcohol or a cleaning solution specifically designed for ribbons.

- Inspect the gears, springs, and other components for any dirt or debris, and clean as necessary.

- Remove the ribbon drive belt and clean it with a lint-free cloth dampened with rubbing alcohol.

- Apply a small amount of dry lubricant to the gears and metal components to prevent wear and tear.

- Reinstall the belt, ribbon, and any other components that were removed.

- Wind the new ribbon onto the cartridge.

- Test the cartridge in a printer to ensure it is working properly.

2. What are the different types of ribbon cartridges?

Ink-based ribbons:

- These use an ink-soaked fabric ribbon.

- They are typically used in dot-matrix printers.

Thermal ribbons:

- These use a heat-activated wax-based ribbon.

- They are typically used in thermal transfer printers.

Resin ribbons:

- These use a durable, chemical-resistant resin-based ribbon.

- They are typically used in industrial printing applications.

3. What are the common problems associated with ribbon cartridges?

Some of the common problems I have encountered with ribbon cartridges include:

- Ribbon tearing or breaking.

- Ribbon jamming or wrinkling.

- Faded or uneven printing.

- Ghosting or smearing on the printed output.

- Ribbon drive belt issues.

4. What are the proper storage conditions for ribbon cartridges?

To ensure optimal performance and longevity, ribbon cartridges should be stored:

- In a cool, dry place, away from direct sunlight.

- In their original packaging or a protective bag.

- Upright, to prevent the ribbon from unwinding.

- At a temperature between 50°F (10°C) and 90°F (32°C).

- With a relative humidity of less than 60%.

5. What safety precautions should be taken when cleaning ribbon cartridges?

It is important to follow these safety precautions when cleaning ribbon cartridges:

- Wear gloves to avoid skin contact with cleaning solutions.

- Use a well-ventilated area to avoid inhaling any fumes.

- Do not use any abrasive cleaning materials or harsh chemicals.

- Ensure that the printer is turned off and unplugged before cleaning.

- Be careful not to damage any of the components while cleaning.

6. What are the benefits of regular ribbon cartridge cleaning?

Regular ribbon cartridge cleaning can provide several benefits, including:

- Improved print quality.

- Reduced risk of ribbon jams and other printing issues.

- Extended lifespan of the ribbon cartridge.

- Reduced need for costly repairs or replacements.

- Improved overall performance of the printer.

7. How often should ribbon cartridges be cleaned?

The frequency of ribbon cartridge cleaning can vary depending on the usage and environment. However, as a general guideline, I recommend cleaning ribbon cartridges:

- Every 6 months for light usage.

- Every 3 months for moderate usage.

- Every 1-2 months for heavy usage.

- More frequently if the printer is used in a dusty or dirty environment.

8. What tools and materials are required for ribbon cartridge cleaning?

To clean a ribbon cartridge, I would need the following tools and materials:

- Soft, lint-free cloths.

- Cotton swabs.

- Rubbing alcohol or a cleaning solution specifically designed for ribbons.

- Dry lubricant (optional).

9. What troubleshooting steps can be taken if a ribbon cartridge is not printing correctly?

If a ribbon cartridge is not printing correctly, I would follow these troubleshooting steps:

- Check the ribbon cartridge for any visible damage or debris.

- Ensure that the ribbon cartridge is properly installed in the printer.

- Clean the ribbon cartridge following the steps mentioned earlier.

- Inspect the printer for any paper jams or other issues that may be affecting print quality.

- Try a different ribbon cartridge to rule out any issues with the cartridge itself.

- Check the printer driver and software settings to ensure they are configured correctly for the type of ribbon cartridge being used.

10. What training or experience do you have in cleaning ribbon cartridges?

I have received comprehensive training on cleaning and maintaining various types of ribbon cartridges. I have hands-on experience in cleaning both ink-based and thermal transfer ribbon cartridges. I am familiar with the different types of ribbon cartridges, their components, and the proper cleaning techniques for each type.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ribbon Cleaner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ribbon Cleaner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Ribbon Cleaners play a vital role in the production process, ensuring the smooth and error-free operation of printing machines. Their primary responsibilities revolve around maintaining the cleanliness and functionality of print ribbons, a critical component in the printing process.

1. Ribbon Maintenance

Performing regular cleaning and maintenance of print ribbons, including removing dust, ink residue, and other contaminants.

- Inspecting ribbons for defects, damage, or wear and replacing them as needed.

- Ensuring proper alignment and tension of ribbons to achieve optimal printing quality.

2. Quality Control

Monitoring print output for defects or inconsistencies and taking corrective action to maintain quality standards.

- Identifying and addressing issues related to ribbon cleanliness, ribbon tension, and other factors that impact print quality.

- Working closely with quality control teams to identify and resolve any print-related problems.

3. Troubleshooting

Diagnosing and resolving ribbon-related issues that arise during the printing process.

- Analyzing printing defects and identifying the root cause of problems.

- Implementing corrective measures to eliminate or minimize printing errors caused by ribbon issues.

4. Preventive Maintenance

Performing preventive maintenance tasks to minimize ribbon-related downtime and ensure smooth production.

- Following established maintenance schedules for cleaning, inspection, and replacement of ribbons.

- Monitoring ribbon usage and anticipating potential maintenance needs.

Interview Tips

Preparing for a Ribbon Cleaner interview requires a combination of technical knowledge, problem-solving skills, and attention to detail. By following these tips, you can effectively showcase your qualifications and increase your chances of success.

1. Research the Company and Position

Thoroughly research the company you are applying to, including their industry, products or services, and company culture. This will help you tailor your answers to the specific requirements of the position and demonstrate your interest in the company.

- Visit the company website and social media pages to gather information about their operations and values.

- Read industry publications and news articles to stay up-to-date on the latest printing technologies and trends.

2. Practice Your Answers

Anticipate common interview questions and prepare thoughtful and concise answers that highlight your relevant skills and experience. Practice your answers out loud or with a friend or family member to build confidence and improve your delivery.

- Focus on demonstrating your understanding of ribbon maintenance, troubleshooting, and preventive maintenance procedures.

- Provide specific examples from your previous work experience that showcase your problem-solving abilities and attention to detail.

3. Emphasize Your Technical Skills

Highlight your technical knowledge and skills related to printing machines, ribbon handling, and quality control. Explain how you have applied these skills in previous roles to ensure optimal print quality and minimize downtime.

- Discuss your experience with different types of printing machines and ribbon technologies.

- Mention any certifications or training programs you have completed to enhance your technical proficiency.

4. Showcase Your Problem-Solving Abilities

Demonstrate your ability to identify and resolve ribbon-related issues quickly and efficiently. Provide examples of troubleshooting scenarios where you successfully diagnosed problems and implemented effective solutions.

- Describe a situation where you identified a print quality defect caused by ribbon contamination and resolved it by cleaning and aligning the ribbon.

- Explain how you used analytical skills to trace an intermittent printing issue to a faulty ribbon sensor and replaced the sensor to restore functionality.

5. Highlight Your Attention to Detail

Emphasize your keen eye for detail and your commitment to maintaining high standards of cleanliness and precision. Explain how your attention to detail has helped you ensure the consistent production of high-quality printed materials.

- Share examples of how you meticulously inspect ribbons for defects and take proactive measures to prevent potential issues.

- Describe how your attention to detail has helped you identify and address minor variations in ribbon tension that could impact print quality.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Ribbon Cleaner interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!