Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Roll Changer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

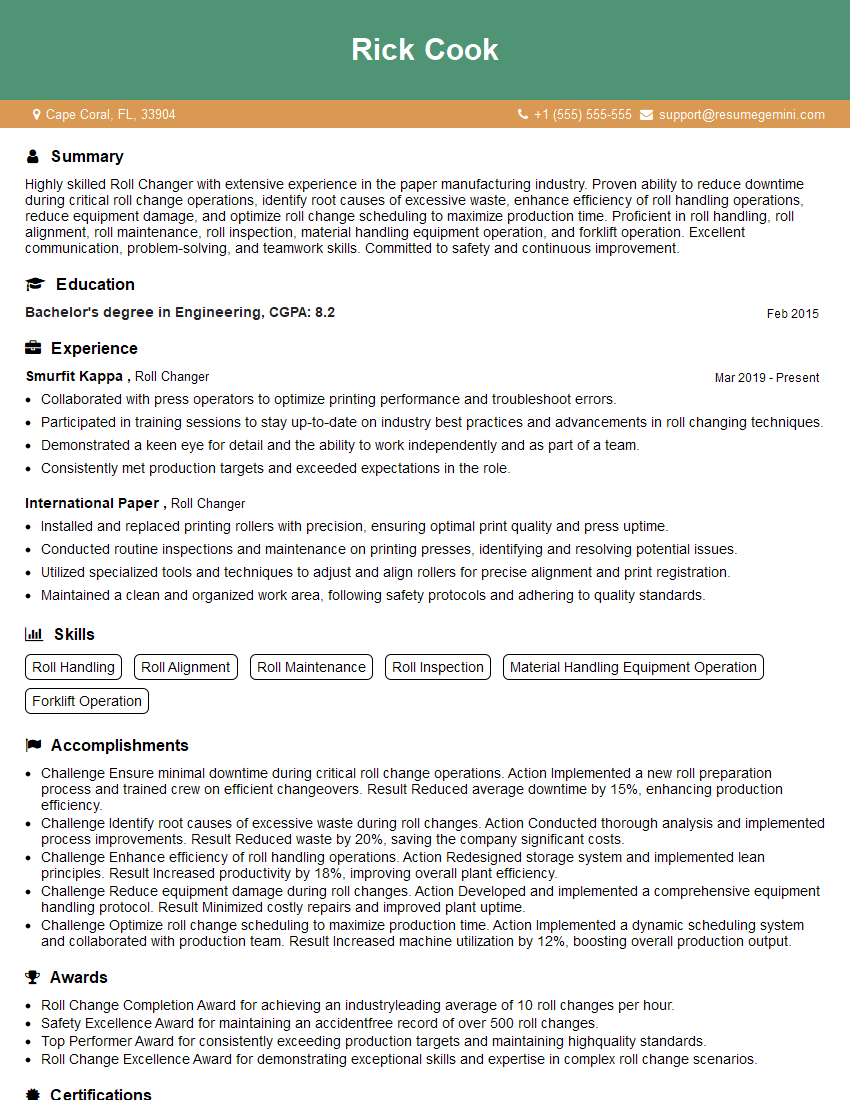

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Roll Changer

1. What is the process of roll changing in a rolling mill?

- Safely remove the existing roll from the mill.

- Inspect the roll and mill for any damage or wear

- Pre-heat the new roll to the required temperature

- Lift and position the new roll into the mill

- Securely fasten the new roll into place

- Check and adjust the roll settings as required

- Restart the mill and monitor the roll performance

2. What are the different types of rolls used in a rolling mill?

Forged Rolls

- Exceptional strength and durability

- Suitable for demanding applications with high loads

Cast Rolls

- Lower cost compared to forged rolls

- Can be customized to specific requirements

Composite Rolls

- Combination of different materials for specific performance requirements

- Offer improved wear resistance and longer lifespan

3. What are the key factors to consider when choosing the right roll for a rolling mill application?

- Material properties being rolled

- Required surface finish

- Roll diameter and length

- Operating temperature and pressure

- Cost and availability

4. What are the different types of roll changing equipment used in a rolling mill?

- Overhead cranes

- Roll handling machines

- Hydraulic roll extractors

- Roll heating furnaces

5. What are the safety precautions that must be followed during roll changing operations?

- Use proper lifting equipment and follow safe rigging procedures

- Wear appropriate PPE including hard hat, safety glasses, and gloves

- Ensure the mill is properly isolated and locked out before starting work

- Inspect the rolls and equipment for any damage or defects before use

- Never attempt to work on a live mill

6. What are the common challenges faced during roll changing operations?

- Roll stuck in the mill due to pressure or deformation

- Improper roll alignment leading to uneven rolling

- Equipment malfunctions or failures

- Safety hazards due to heavy equipment and high temperatures

7. How do you ensure that the roll change is performed efficiently and with minimal downtime?

- Plan and prepare thoroughly

- Use the right tools and equipment

- Follow established procedures

- Involve experienced personnel

- Communicate effectively with all team members

8. What is the importance of roll maintenance in a rolling mill operation?

- Extends roll life and reduces downtime

- Improves roll performance and product quality

- Reduces energy consumption and operating costs

- Ensures safe and efficient mill operations

9. Describe the different methods used for roll grinding and reconditioning

- Cylindrical grinding

- Surface grinding

- Roll honing

- Roll texturing

10. How do you keep up-to-date with the latest advances in roll changing technology and best practices?

- Attend industry conferences and exhibitions

- Read technical journals and publications

- Network with other roll changing professionals

- Participate in training and development programs

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Roll Changer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Roll Changer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Roll Changers play a pivotal role in manufacturing and printing industries by ensuring seamless operations. Their primary responsibilities include:

1. Roll Handling

Efficiently handling and replacing various rolls used in machinery, including paper, film, and fabric rolls.

- Loading and unloading rolls using manual or mechanical devices.

- Inspecting rolls for defects or damage.

2. Machine Operation

Operating roll-changing machines precisely to ensure proper alignment and tension of rolls.

- Calibrating machine settings and monitoring gauges.

- Maintaining optimal machine performance and troubleshooting minor issues.

3. Safety Compliance

Adhering to safety protocols and handling equipment safely.

- Wearing appropriate safety gear and observing proper lifting techniques.

- Following established procedures to minimize risks and accidents.

4. Other Responsibilities

Additional responsibilities may include:

- Assisting with equipment maintenance and repairs.

- Maintaining a clean and organized work area.

- Communicating effectively with supervisors and other team members.

Interview Tips

To ace an interview for a Roll Changer position, candidates should prepare thoroughly. Here are some key tips:

1. Research the Company and Industry

Research the company’s background, industry trends, and specific requirements for the role.

- Visit the company website and LinkedIn page.

- Read industry publications and articles.

2. Study Job Description

Carefully review the job description to identify the essential responsibilities and qualifications.

- Prepare examples from your experience that align with each requirement.

- Quantify your accomplishments whenever possible.

3. Practice Common Interview Questions

Practice answering common interview questions, such as:

- Tell me about your experience with roll changing.

- How do you ensure safety in a manufacturing environment?

4. Highlight Relevant Skills

Emphasize your proficiency in relevant skills, including:

- Attention to detail.

- Physical fitness and stamina.

- Mechanical aptitude.

5. Prepare Questions for the Interviewer

Show interest and engagement by preparing thoughtful questions for the interviewer, such as:

- Can you describe the company’s safety culture?

- What opportunities are there for professional development?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Roll Changer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!