Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Roll Plugger Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

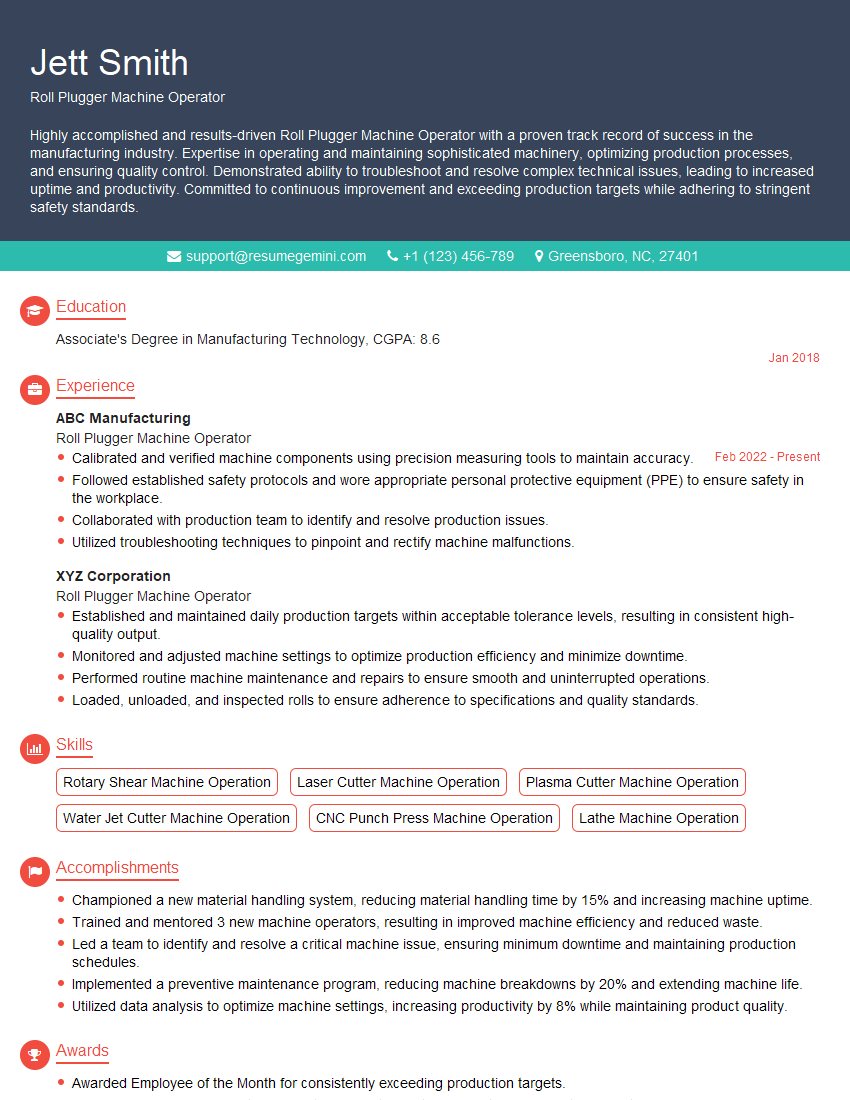

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Roll Plugger Machine Operator

1. What are the key responsibilities of a Roll Plugger Machine Operator?

As a Roll Plugger Machine Operator, my primary responsibilities would include:

- Efficiently operating the roll plugger machine to plug rolls of fabric.

- Maintaining and adjusting the machine to ensure optimal performance and prevent breakdowns.

- Monitoring the production process to identify and resolve any issues promptly.

- Loading and unloading fabric rolls, ensuring proper alignment and tension.

- Inspecting finished rolls for quality and ensuring they meet specifications.

2. Describe the different types of fabric materials that can be plugged using a roll plugger machine.

Roll plugger machines can handle various fabric materials, including:

- Natural fibers: Cotton, linen, wool, silk.

- Synthetic fibers: Polyester, nylon, rayon, spandex.

- Blended fabrics: Combinations of natural and synthetic fibers.

- Woven, knit, or non-woven fabrics.

3. What are the essential machine settings and parameters that need to be monitored and adjusted by the Roll Plugger Machine Operator?

To ensure efficient and accurate roll plugging, I would monitor and adjust the following parameters:

- Roll tension: To prevent stretching or tearing.

- Plug density: To achieve the desired level of firmness.

- Plug type: To suit the fabric material and application.

- Machine speed: To optimize throughput while maintaining quality.

- Temperature: To ensure proper bonding and prevent damage to the fabric.

4. What preventive maintenance tasks are typically performed on a roll plugger machine?

Regular maintenance is crucial to prevent breakdowns and ensure optimal performance. I would conduct the following tasks:

- Cleaning and lubricating moving parts.

- Inspecting and replacing worn or damaged components.

- Calibrating sensors and gauges.

- Monitoring oil and fluid levels.

- Performing safety checks before and after operation.

5. What troubleshooting steps would you take if the roll plugger machine experiences a jam or malfunction?

In the event of a jam or malfunction, I would follow these troubleshooting steps:

- Stop the machine immediately.

- Identify the source of the problem (e.g., fabric blockage, sensor failure).

- Clear the jam or repair the malfunctioning component.

- Restart the machine and monitor its performance.

- If the issue persists, seek assistance from a qualified technician.

6. How do you ensure that the plugged rolls meet the desired quality standards?

To ensure quality, I would perform the following steps:

- Visually inspect the rolled fabric for proper alignment, tension, and plug distribution.

- Use measuring tools to check the roll diameter and density.

- Conduct tensile strength tests to ensure the fabric’s integrity.

- Maintain detailed records of production and quality checks.

7. What safety protocols and regulations must be followed when operating a roll plugger machine?

Safety is paramount. I would adhere to the following protocols:

- Wear appropriate personal protective equipment (PPE), such as gloves, protective eyewear, and earplugs.

- Keep the work area clean and free of tripping hazards.

- Follow lock-out/tag-out procedures before performing maintenance.

- Be aware of moving parts and potential pinch points.

- Report any unsafe conditions or potential hazards immediately.

8. How do you optimize the efficiency and productivity of the roll plugging process?

To enhance efficiency and productivity, I would:

- Establish and follow standardized operating procedures.

- Use proper machine settings and parameters.

- Minimize downtime through preventive maintenance.

- Identify and eliminate bottlenecks in the production process.

- Continuously seek ways to improve and streamline operations.

9. Describe a time when you successfully resolved a complex issue related to roll plugging.

During a previous role as a Roll Plugger Machine Operator, I encountered an issue where the machine was producing rolls with uneven plug distribution. I thoroughly inspected the machine, identified a misaligned sensor, and recalibrated it. By doing so, I was able to resolve the problem and ensure the production of high-quality rolls.

10. What do you see as the future trends and advancements in the field of roll plugging technology?

The roll plugging industry is continuously evolving. I anticipate advancements in:

- Automation and robotics for increased efficiency.

- Improved sensor technology for better quality control.

- Sustainable materials and processes to reduce environmental impact.

- Data analytics for predictive maintenance and process optimization.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Roll Plugger Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Roll Plugger Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Roll Plugger Machine Operators are responsible for operating and maintaining roll plugging machines, which insert plugs into holes in metal or plastic sheets. Their key responsibilities include:

1. Machine Operation

Set up and operate roll plugging machines according to specifications.

2. Quality Control

Inspect plugs for defects and ensure they meet quality standards.

3. Maintenance

Perform routine maintenance on roll plugging machines, including cleaning, lubrication, and minor repairs.

4. Troubleshooting

Identify and resolve operational issues with roll plugging machines.

Interview Tips

Preparing for a Roll Plugger Machine Operator interview requires understanding the key responsibilities and demonstrating your skills and experience. Here are some tips to help you ace the interview:

1. Highlight Relevant Experience

Emphasize your experience operating and maintaining similar machinery. Quantify your accomplishments and provide specific examples of your successes.

2. Research the Company

Learn about the company’s industry, products, and culture. This demonstrates your interest and enthusiasm for the role.

3. Prepare for Technical Questions

Familiarize yourself with the technical aspects of roll plugging machines. Be prepared to answer questions about machine setup, operation, and troubleshooting.

4. Practice Active Listening

Pay close attention to the interviewer’s questions and respond thoughtfully. Ask clarifying questions to show your understanding.

5. Showcase Problem-Solving Skills

Provide examples of how you have identified and resolved issues with machines or processes. Focus on your analytical and problem-solving abilities.

6. Emphasize Quality Control

Highlight your commitment to quality and your ability to ensure that plugs meet specifications. Share examples of your quality control procedures.

7. Be Enthusiastic and Professional

Convey your passion for the role and your eagerness to contribute to the team. Maintain a professional demeanor throughout the interview.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Roll Plugger Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Roll Plugger Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.