Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Screener and Blender Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

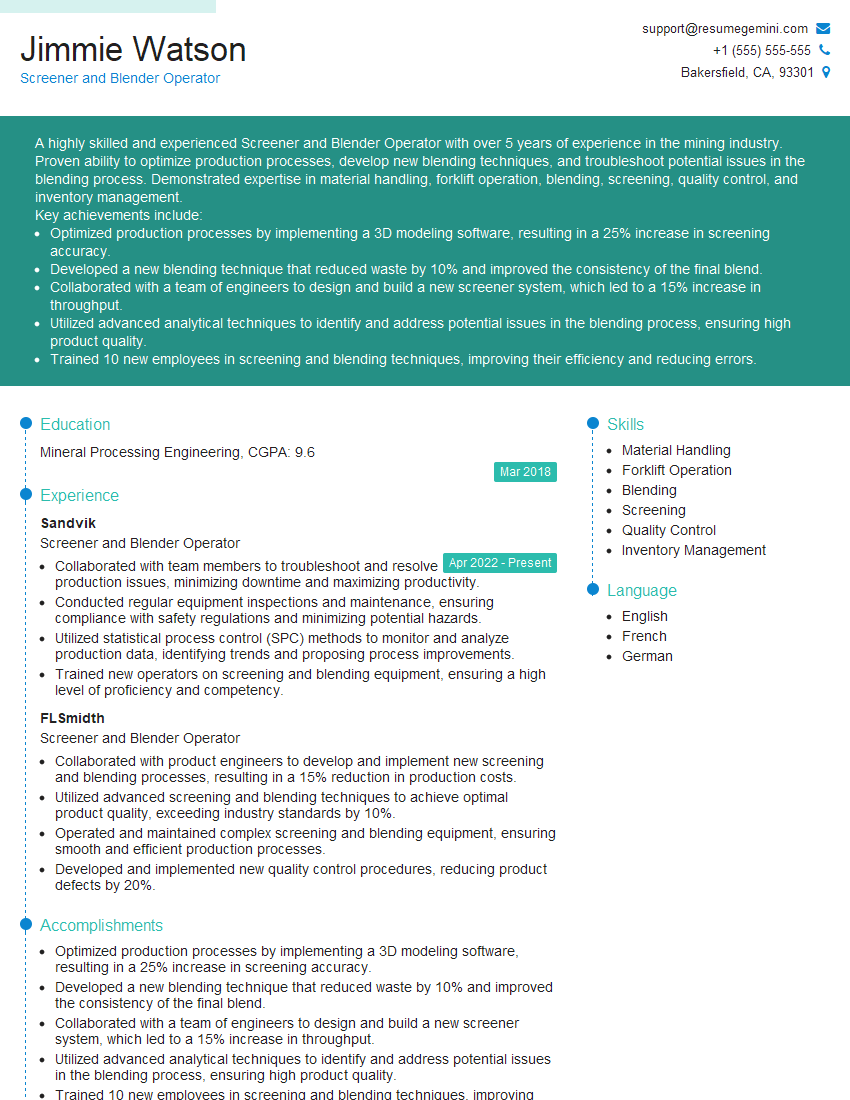

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Screener and Blender Operator

1. Can you describe the process of screening a sample?

As a Screener Operator, my responsibilities involve meticulously screening samples to remove unwanted materials. The process I follow typically includes the following steps:

- Sample Preparation: Preparing the sample by removing any contaminants or foreign objects that could interfere with screening.

- Screen Selection: Choosing the appropriate screen size and type based on the desired particle size distribution.

- Sample Loading: Carefully loading the sample onto the screen, ensuring even distribution.

- Screening: Operating the screening machine to separate the sample into various fractions based on size.

- Fraction Collection: Collecting the screened fractions in designated containers for further analysis or processing.

2. What are the different types of screens used in screening?

Types of Screens:

- Woven Wire Screens: Constructed from interwoven metal wires, they offer precise particle separation and durability.

- Perforated Plate Screens: Consisting of perforated holes in a metal plate, they provide consistent particle size distribution.

- Slotted Screens: Featuring slots instead of holes, they are ideal for separating elongated or irregularly shaped particles.

- Bar Screens: Made of parallel metal bars, they are commonly used for removing large debris or trash from liquids.

Factors Influencing Screen Selection:

- Particle Size: Selecting a screen with an appropriate aperture size for the desired particle size separation.

- Material Properties: Considering the material’s hardness, abrasiveness, and moisture content when choosing the screen type.

- Capacity and Efficiency: Choosing a screen that can handle the required volume and provide efficient screening.

3. What are the most common issues encountered during screening?

During screening operations, several common issues can arise. These include:

- Screen Clogging: Accumulation of particles on the screen surface, hindering proper separation.

- Feed Rate Variations: Inconsistent feed rates can affect screening efficiency and accuracy.

- Equipment Malfunctions: Mechanical failures or electrical problems can disrupt the screening process.

- Screen Wear and Tear: Over time, screens can become worn or damaged due to abrasive materials or aggressive operating conditions.

- Sample Contamination: External contaminants or improper handling can compromise the purity of the screened products.

4. How do you ensure the accuracy and consistency of the screening process?

Maintaining the accuracy and consistency of the screening process is crucial. I employ several measures to achieve this:

- Regular Screen Calibration: Calibrating screens at regular intervals ensures they meet the desired particle size specifications.

- Optimized Feed Rate: Maintaining a consistent feed rate optimizes screening efficiency and prevents screen overloading.

- Equipment Maintenance: Regular maintenance and inspections keep equipment running smoothly, minimizing disruptions.

- Quality Control Checks: Implementing quality control checks, such as sampling and analysis, verifies the accuracy of the screening results.

- Operator Training: Providing adequate training to operators ensures they follow standardized procedures and operate the equipment correctly.

5. Can you describe the role of a Blender Operator?

As a Blender Operator, my primary responsibility is to operate and maintain industrial blenders used for mixing various materials. My tasks involve:

- Recipe Execution: Following specified recipes to accurately weigh, load, and blend ingredients.

- Equipment Operation: Operating blenders of different sizes and capacities, ensuring they mix materials thoroughly and consistently.

- Quality Control: Monitoring the blending process, taking samples, and performing quality checks to ensure product specifications are met.

- Equipment Maintenance: Performing routine maintenance and cleaning of blenders to maintain optimal performance.

- Safety Compliance: Adhering to established safety protocols and procedures while operating blending equipment.

6. What are the different types of blenders used in the industry?

Various types of blenders are used depending on the specific mixing requirements. Common types include:

Batch Blenders:

- Ribbon Blenders: Used for gentle mixing of dry powders and granules.

- Paddle Blenders: Suitable for blending materials with different densities and flow characteristics.

- Tumble Blenders: Ideal for mixing fragile or shear-sensitive materials.

Continuous Blenders:

- Screw Blenders: Continuously mix materials as they are conveyed through a screw.

- Pug Mill Blenders: Suitable for mixing viscous or dough-like materials.

- Cone Blenders: Used for blending large volumes of powders and granules.

7. How do you determine the optimal blending time and speed for a given mixture?

Determining the optimal blending time and speed is critical for achieving uniform mixtures. I consider several factors:

- Material Properties: Different materials have varying mixing characteristics based on their particle size, density, and flowability.

- Desired Homogeneity: The level of mixing required influences the blending time and speed.

- Blender Type: The capabilities and mixing action of the blender used impact the optimal settings.

- Batch Size: The volume of material being blended affects the mixing time and speed.

- Experience and Knowledge: Practical experience and knowledge of blending principles guide my decision-making.

8. What are the most common challenges faced in blending operations?

Several challenges can arise during blending operations, including:

- Material Segregation: Different materials may tend to separate during mixing, requiring additional mixing time or techniques.

- Incomplete Mixing: Achieving uniform mixing can be challenging, especially when dealing with materials with different properties.

- Equipment Malfunctions: Mechanical or electrical issues with blenders can disrupt operations and affect product quality.

- Environmental Factors: Temperature, humidity, and other environmental factors can influence the mixing process and final product quality.

- Safety Hazards: Operating blenders involves potential hazards such as moving machinery, dust, and chemical exposure.

9. How do you ensure the quality of blended products?

Maintaining product quality is paramount in blending operations. I employ the following measures:

- Recipe Adherence: Accurately following specified recipes ensures the correct proportions and consistency of ingredients.

- Regular Sampling and Testing: Taking samples and performing quality tests verifies that the blended products meet the required specifications.

- Equipment Calibration: Calibrating blenders regularly ensures accurate weighing and mixing.

- Process Monitoring: Monitoring the blending process in real-time allows for timely adjustments as needed.

- Documentation and Traceability: Maintaining detailed records of blending operations ensures traceability and facilitates quality investigations.

10. Can you describe a situation where you successfully resolved a blending problem?

In a previous role, I encountered a problem where a blended product was not meeting the desired viscosity specifications. I conducted a thorough investigation, considering the material properties, blending parameters, and equipment performance. I identified that the blender speed was set too low, resulting in insufficient mixing. By adjusting the speed to the optimal setting, I was able to achieve the desired product viscosity, resolving the issue and ensuring product quality.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Screener and Blender Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Screener and Blender Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Screener and Blender Operator is a skilled professional who plays a crucial role in manufacturing and processing operations. Their primary responsibilities involve screening, blending, and packaging materials to ensure their quality and consistency.

1. Screening and Blending

The core responsibility of a Screener and Blender Operator is to operate screening and blending equipment to separate, size, and mix different materials. They use vibrating screens or other mechanical devices to remove impurities from incoming raw materials. Additionally, they blend materials in controlled proportions to achieve specific product specifications.

- Operate screening equipment to separate materials based on size or other characteristics.

- Adjust equipment settings, such as screen mesh size and vibration speed, to optimize screening efficiency.

- Mix and blend different materials according to specified ratios to obtain the desired product composition.

2. Equipment Maintenance and Troubleshooting

Screener and Blender Operators are responsible for maintaining their equipment to ensure smooth operations. They conduct routine inspections, identify potential problems, and perform necessary repairs or adjustments.

- Inspect and maintain screening and blending equipment to ensure proper functionality.

- Identify and troubleshoot equipment malfunctions, taking appropriate corrective actions.

3. Quality Control and Sampling

To ensure the quality of the finished products, Screener and Blender Operators perform quality control checks by taking samples of materials and testing their properties. They ensure that the products meet established standards and specifications.

- Collect and analyze samples to monitor the quality of incoming and finished products.

- Report any deviations from specifications to supervisors or management.

4. Safety and Compliance

Screener and Blender Operators prioritize safety in the workplace. They adhere to safety regulations, wear appropriate protective gear, and follow established operating procedures to prevent accidents.

- Follow safety protocols and operating procedures to minimize risks.

- Wear appropriate personal protective equipment (PPE) to ensure safety during operations.

Interview Tips

Preparing thoroughly for an interview is essential to showcase your skills and qualifications. Here are some tips to help you ace your interview as a Screener and Blender Operator:

1. Research the Company and Position

Before the interview, research the company’s background, industry, and the specific role you are applying for. This knowledge will help you understand the company’s culture and the expectations of the position.

- Visit the company’s website and social media pages.

- Review the job description thoroughly and note the key responsibilities.

2. Highlight Relevant Experience and Skills

During the interview, emphasize your previous experience and skills that are relevant to the role of a Screener and Blender Operator. Share specific examples of how you have used these skills in your past positions.

- Quantify your accomplishments using specific metrics or achievements.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide context.

3. Demonstrate Understanding of Equipment and Processes

Show the interviewer that you have a solid understanding of screening and blending equipment, as well as the underlying processes involved. Explain how you have operated and maintained similar equipment in your previous roles.

- Discuss different types of screening and blending equipment and their applications.

- Explain the principles of screening and blending processes and how they affect product quality.

4. Emphasize Safety and Attention to Detail

Stress your commitment to safety and attention to detail in your work. Provide examples of how you have followed safety protocols and maintained high standards of precision in your previous positions.

- Describe your understanding of industry safety regulations.

- Highlight your ability to identify and resolve potential quality issues.

5. Prepare Questions

At the end of the interview, prepare thoughtful questions for the interviewer to demonstrate your interest in the role and the company. This shows that you are engaged and eager to learn more.

- Ask about the company’s growth plans and industry trends.

- Inquire about opportunities for professional development and training.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Screener and Blender Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Screener and Blender Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.