Are you gearing up for an interview for a Shaker Out position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Shaker Out and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

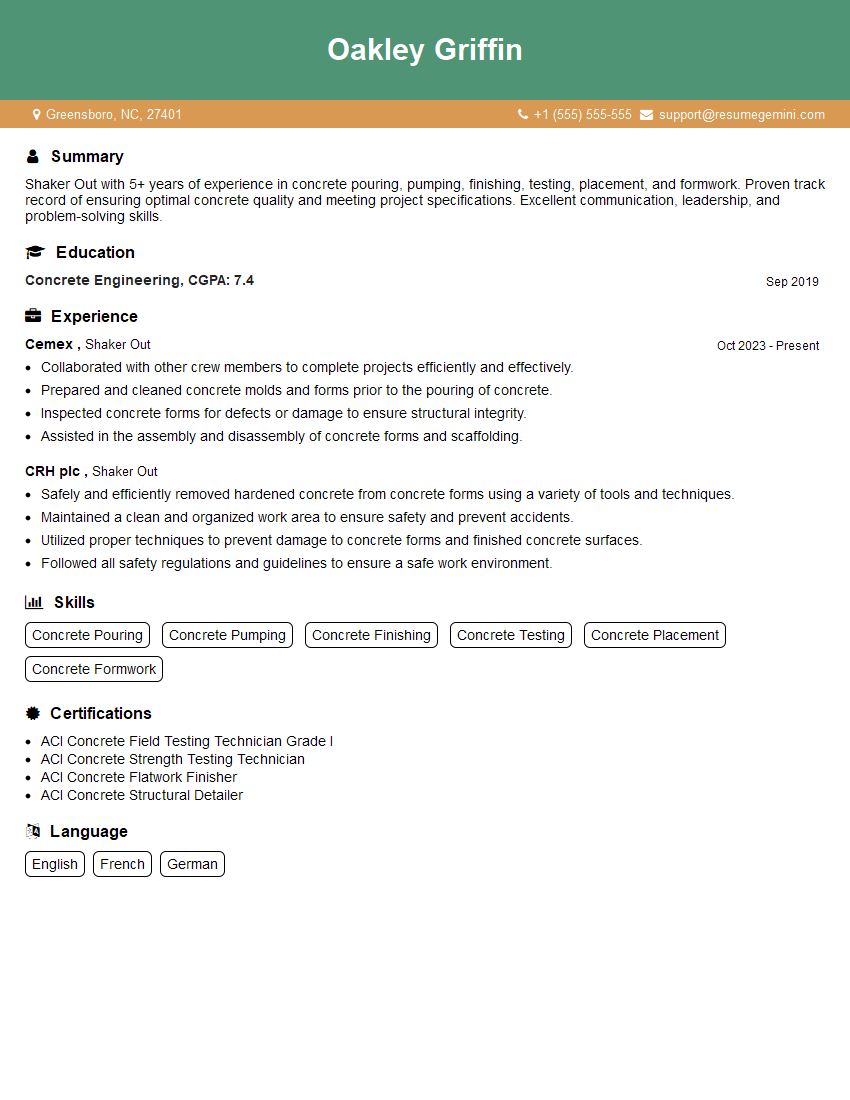

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Shaker Out

1. What are the key factors to consider when designing a shaker out?

The key factors to consider when designing a shaker out are:

- The size and shape of the part being shaken out

- The weight of the part being shaken out

- The material of the part being shaken out

- The desired shake out time

- The available space for the shaker out

- The budget for the shaker out

2. What are the different types of shaker outs?

The different types of shaker outs are:

- Simple shaker outs

- Gravity shaker outs

- Vibratory shaker outs

- Pneumatic shaker outs

- Hydraulic shaker outs

- Linear shaker outs

- Rotary shaker outs

- Custom shaker outs

3. What are the advantages and disadvantages of each type of shaker out?

The advantages and disadvantages of each type of shaker out are:

- Simple shaker outs are simple in design and operation, and are relatively inexpensive to manufacture and maintain. However, they are not as efficient as other types of shaker outs, and can be difficult to use for large or heavy parts.

- Gravity shaker outs use gravity to move the part being shaken out, and are therefore very efficient. However, they are only suitable for parts that are not too heavy.

- Vibratory shaker outs use vibrations to move the part being shaken out, and are very efficient for large or heavy parts. However, they can be noisy and can cause damage to delicate parts.

- Pneumatic shaker outs use compressed air to move the part being shaken out, and are very powerful. However, they can be expensive to operate and maintain.

- Hydraulic shaker outs use hydraulic fluid to move the part being shaken out, and are very powerful and efficient. However, they can be expensive to operate and maintain.

- Linear shaker outs move the part being shaken out in a linear motion, and are very efficient for large or heavy parts. However, they can be expensive to manufacture and maintain.

- Rotary shaker outs move the part being shaken out in a rotary motion, and are very efficient for small or delicate parts. However, they can be expensive to manufacture and maintain.

- Custom shaker outs are designed to meet the specific needs of a particular application, and can offer a variety of advantages and disadvantages.

4. How do you select the right shaker out for a particular application?

The following factors should be considered when selecting a shaker out for a particular application:

- The size and shape of the part being shaken out

- The weight of the part being shaken out

- The material of the part being shaken out

- The desired shake out time

- The available space for the shaker out

- The budget for the shaker out

- The experience and expertise of the shaker out manufacturer

5. What are the common mistakes that people make when selecting a shaker out?

The common mistakes that people make when selecting a shaker out are:

- Not considering the size and shape of the part being shaken out

- Not considering the weight of the part being shaken out

- Not considering the material of the part being shaken out

- Not considering the desired shake out time

- Not considering the available space for the shaker out

- Not considering the budget for the shaker out

- Not considering the experience and expertise of the shaker out manufacturer

6. What are the maintenance requirements for a shaker out?

The maintenance requirements for a shaker out are:

- Regular cleaning and inspection

- Replacement of worn or damaged parts

- Calibration and adjustment as needed

7. What are the safety precautions that should be taken when using a shaker out?

The safety precautions that should be taken when using a shaker out are:

- Wear appropriate safety gear, including eye protection, gloves, and ear protection

- Be aware of the location of all moving parts

- Do not operate the shaker out unless it is properly installed and maintained

- Do not overload the shaker out

- Do not operate the shaker out in a hazardous environment

8. What are the troubleshooting tips for a shaker out?

The troubleshooting tips for a shaker out are:

- Check the power supply

- Check the fuses or circuit breakers

- Check the wiring

- Check the motor

- Check the hydraulic system

- Check the pneumatic system

- Check the control system

- Check the bearings

- Check the lubrication system

9. What are the latest trends in shaker out technology?

The latest trends in shaker out technology are:

- The use of more efficient motors

- The use of more durable materials

- The use of more sophisticated control systems

- The development of new shaker out designs

10. What are the future prospects for the shaker out industry?

The future prospects for the shaker out industry are positive. The demand for shaker outs is expected to grow in the coming years, due to the increasing use of automated manufacturing processes. The development of new shaker out technologies is expected to further drive growth in the industry.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Shaker Out.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Shaker Out‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Shaker Out plays a vital role in the concrete construction industry, primarily responsible for operating and maintaining concrete vibration equipment. Their meticulous work ensures the proper consolidation and removal of air pockets from freshly poured concrete, resulting in enhanced durability and structural stability of concrete structures.

1. Equipment Operation and Maintenance

Skilled in operating various types of concrete vibration equipment, including vibrators, screeds, and tampers.

- Thoroughly inspecting equipment before and after use to ensure optimal performance and safety.

- Performing routine maintenance tasks, such as cleaning, lubrication, and minor repairs, to maintain equipment efficiency.

2. Concrete Vibration

Expertly employing vibration techniques to remove air pockets and consolidate freshly poured concrete.

- Determining the appropriate vibration frequency and duration for different concrete mixtures and placement conditions.

- Positioning and manipulating vibrators to achieve uniform consolidation and prevent honeycombing or segregation.

3. Surface Finishing

Assisting in surface finishing operations to achieve the desired texture and smoothness of concrete surfaces.

- Using screeds and bull floats to level and smooth concrete surfaces, ensuring proper drainage and preventing surface defects.

- Applying curing compounds or protective coatings to protect and enhance the longevity of concrete surfaces.

4. Quality Control

Monitoring and maintaining concrete quality by adhering to established specifications and standards.

- Observing concrete placement and consolidation processes to identify potential issues and recommend corrective measures.

- Documenting concrete vibration and surface finishing procedures to ensure consistency and adherence to quality standards.

Interview Tips

To ace an interview for the position of Shaker Out, it is essential to prepare comprehensively and present yourself as a competent and enthusiastic candidate. Here are some valuable tips to assist you in your preparation:

1. Research the Company and Industry

Demonstrate your interest in the company and the concrete construction industry by thoroughly researching their background, projects, and industry trends.

- Visit the company’s website, LinkedIn page, and other online resources to gather information about their operations, values, and recent developments.

- Keep abreast of industry news and publications to show your passion for the field and your understanding of its challenges and advancements.

2. Highlight Your Skills and Experience

Emphasize your proficiency in concrete vibration techniques, equipment operation and maintenance, and surface finishing. Provide specific examples of projects where you have successfully applied these skills.

- Quantify your accomplishments whenever possible using metrics such as the number of cubic yards of concrete vibrated or the percentage of surfaces finished to specifications.

- Be prepared to discuss your knowledge of different types of concrete mixtures, vibration equipment, and industry standards.

3. Showcase Your Commitment to Quality

Convey your commitment to delivering high-quality results by highlighting your attention to detail, adherence to specifications, and proactive problem-solving.

- Describe instances where you identified potential issues during concrete placement or vibration and implemented effective corrective measures.

- Explain your understanding of the importance of proper consolidation and surface finishing for the structural integrity and durability of concrete structures.

4. Prepare for Common Interview Questions

Practice answering common interview questions to demonstrate your understanding of the role and your suitability for the position.

- “Describe your experience in operating and maintaining concrete vibration equipment.” “Tell us about a project where you faced a challenge during concrete vibration and how you overcame it.” “How do you ensure the proper consolidation of concrete in difficult-to-reach areas?” “What is your understanding of the importance of surface finishing and how do you achieve a high-quality finish?”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Shaker Out interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!