Are you gearing up for a career in Ski Molder? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Ski Molder and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

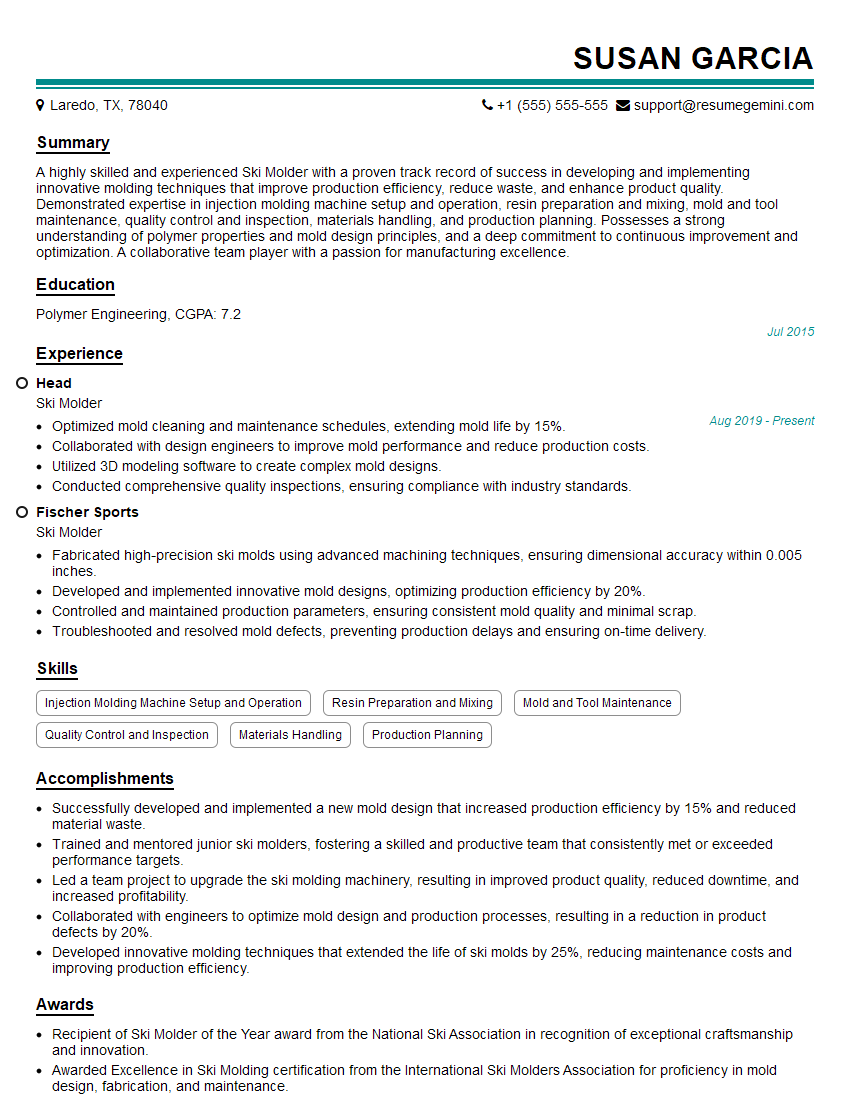

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ski Molder

1. Can you describe the different types of ski molds and their uses?

Ski molds are used to shape and press skis. There are three main types of ski molds:

- Compression molds: These molds use heat and pressure to compress the ski core and shape it into the desired shape.

- Injection molds: These molds use a heated injection system to inject molten plastic into the mold, which then cools and solidifies into the desired shape.

- Transfer molds: These molds use a heated press to transfer the ski core from one mold to another, which then shapes it into the desired shape.

2. What are the key factors to consider when designing a ski mold?

The key factors to consider when designing a ski mold include:

Material selection

- The material used for the mold will affect its durability, heat resistance, and ease of use

- Common materials used for ski molds include aluminum, steel, and composite materials

Mold geometry

- The geometry of the mold will determine the shape of the finished ski

- Factors to consider include the ski’s length, width, camber, and sidecut

Mold temperature

- The temperature of the mold will affect the curing time and quality of the finished ski

- The ideal temperature will vary depending on the material used for the mold and the type of ski being produced

Mold pressure

- The pressure applied to the mold will affect the density and strength of the finished ski

- The ideal pressure will vary depending on the material used for the mold and the type of ski being produced

3. What are the different types of ski materials and their advantages and disadvantages?

The different types of ski materials and their advantages and disadvantages include:

- Wood: Wood is a traditional ski material that is lightweight and provides good flex and rebound.

- Metal: Metal is a durable ski material that provides good edge hold and stability.

- Composite materials: Composite materials are a combination of wood, metal, and other materials that offer a range of performance characteristics.

4. What are the different types of ski construction and their advantages and disadvantages?

The different types of ski construction and their advantages and disadvantages include:

- Sandwich construction: Sandwich construction is a lightweight ski construction that uses a wood core sandwiched between two layers of fiberglass or carbon fiber.

- Cap construction: Cap construction is a durable ski construction that uses a wood core covered with a layer of fiberglass or carbon fiber.

- Monocoque construction: Monocoque construction is a lightweight and stiff ski construction that uses a single layer of fiberglass or carbon fiber.

5. What are the different types of ski profiles and their advantages and disadvantages?

The different types of ski profiles and their advantages and disadvantages include:

- Camber: Camber is a traditional ski profile that provides good edge hold and stability.

- Rocker: Rocker is a newer ski profile that provides good floatation in powder and easy turning.

- Hybrid: Hybrid is a ski profile that combines camber and rocker to provide a range of performance characteristics.

6. What are the different types of ski bindings and their advantages and disadvantages?

The different types of ski bindings and their advantages and disadvantages include:

- Alpine bindings: Alpine bindings are the most common type of ski binding. They provide a secure connection between the skier and the ski and allow for quick release in the event of a fall.

- Telemark bindings: Telemark bindings allow the skier to flex their heels and knees, which provides a more natural skiing motion.

- Nordic bindings: Nordic bindings are designed for cross-country skiing and provide a secure connection between the skier and the ski while allowing for a free range of motion.

7. What are the different types of ski accessories and their uses?

The different types of ski accessories and their uses include:

- Ski poles: Ski poles are used to help the skier balance and move around on the snow.

- Ski boots: Ski boots provide support and protection for the skier’s feet and ankles.

- Ski helmets: Ski helmets protect the skier’s head from injury in the event of a fall.

- Ski goggles: Ski goggles protect the skier’s eyes from the sun and wind.

- Ski clothing: Ski clothing is designed to keep the skier warm and dry in cold and wet conditions.

8. What are the different types of ski maintenance and how often should they be performed?

The different types of ski maintenance and how often they should be performed include:

- Ski waxing: Ski waxing is the process of applying a thin layer of wax to the base of the skis to improve their glide and performance. It should be performed regularly, especially after skiing in wet or icy conditions.

- Ski sharpening: Ski sharpening is the process of filing the edges of the skis to improve their grip on the snow. It should be performed as needed, especially after skiing on hard or icy surfaces.

- Ski binding adjustment: Ski binding adjustment is the process of adjusting the bindings to ensure they are properly fitted to the skier and provide a secure connection between the skier and the ski. It should be performed before each skiing session.

9. What are the safety guidelines for skiing?

The safety guidelines for skiing include:

- Always wear a ski helmet.

- Stay within your ability level and ski on terrain that is appropriate for your skill level.

- Be aware of your surroundings and other skiers and snowboarders.

- Stay hydrated and take breaks as needed.

- Never ski alone.

- Have fun!

10. What are the current trends in the ski industry?

The current trends in the ski industry include:

- The rise of backcountry skiing: More and more skiers are venturing off the beaten path and into the backcountry in search of fresh powder and untracked terrain.

- The growing popularity of ski touring: Ski touring is a great way to get exercise and enjoy the beauty of the backcountry without the need for a lift ticket.

- The development of new ski technology: New ski technology is constantly being developed to improve the performance and safety of skiers.

- The increasing popularity of skiing as a family activity: More and more families are discovering the joys of skiing together.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ski Molder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ski Molder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Ski Molders play a pivotal role in the manufacturing process of skis, ensuring the efficient production of high-quality products. Their primary responsibilities include the setup, monitoring, and maintenance of ski molding equipment. Additionally, they are responsible for the proper handling and storage of materials, as well as adherence to safety regulations.

1. Production Operations

As the cornerstone of their role, Ski Molders are responsible for the smooth operation of automated ski molding machines. This involves the programming and calibration of the equipment to ensure optimal performance and product quality.

- Prepare and operate ski molding machines according to established procedures.

- Monitor production processes and make necessary adjustments to maintain efficiency and quality standards.

2. Material Handling

Ski Molders are entrusted with the safe handling and storage of various materials, from raw materials to finished products. Maintaining an organized and efficient work environment is crucial to prevent damage and ensure smooth production.

- Receive and inspect raw materials, ensuring they meet specifications.

- Handle and store materials in designated areas, adhering to safety protocols and inventory management practices.

3. Quality Control

Ensuring the production of high-quality skis is paramount. Ski Molders perform regular inspections of products and monitor production processes to identify and address any defects or inconsistencies.

- Inspect finished skis for defects or deviations from specifications.

- Identify and resolve production issues by analyzing data, making adjustments, and implementing corrective actions.

4. Safety and Maintenance

Ski Molders are responsible for maintaining a safe and efficient work environment. Regular maintenance and adherence to safety regulations are essential to prevent accidents and ensure the longevity of equipment.

- Adhere to safety protocols and regulations, including the use of personal protective equipment (PPE).

- Perform preventive maintenance on ski molding equipment, including cleaning, lubrication, and minor repairs.

Interview Tips

To ace the interview for a Ski Molder position, it is essential to not only possess the necessary skills and qualifications but also to effectively present yourself and your abilities. Here are some tips to help you prepare and make a positive impression:

1. Research the Company and Industry

Demonstrate your interest in the company and the skiing industry. Research their history, products, and reputation to gain insights that will enable you to tailor your responses to the interviewer’s questions.

- Visit the company’s website and social media pages.

- Read articles and industry news to stay informed about the latest trends and technologies.

2. Highlight Relevant Skills and Experience

Emphasize your experience in ski molding or related fields, showcasing your technical abilities and understanding of the industry. Quantify your achievements and provide specific examples that demonstrate your proficiency.

- Describe your experience in operating and maintaining ski molding equipment.

- Share examples of how you have identified and resolved production issues.

3. Be Prepared to Discuss Safety

Safety is a crucial aspect of Ski Molder responsibilities. Highlight your commitment to adhering to safety protocols and regulations. Discuss your experience in identifying and mitigating hazards, and explain how you ensure a safe work environment.

- Describe your experience in using personal protective equipment (PPE).

- Share examples of how you have implemented safety measures to prevent accidents.

4. Demonstrate Problem-Solving Abilities

Ski Molders are often faced with unexpected challenges. Showcase your problem-solving skills by providing examples of how you have analyzed situations, identified root causes, and implemented effective solutions.

- Describe a scenario where you encountered a production issue and how you resolved it.

- Explain your approach to troubleshooting and finding innovative solutions.

Next Step:

Now that you’re armed with the knowledge of Ski Molder interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Ski Molder positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini