Are you gearing up for a career in Soot Blower? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Soot Blower and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

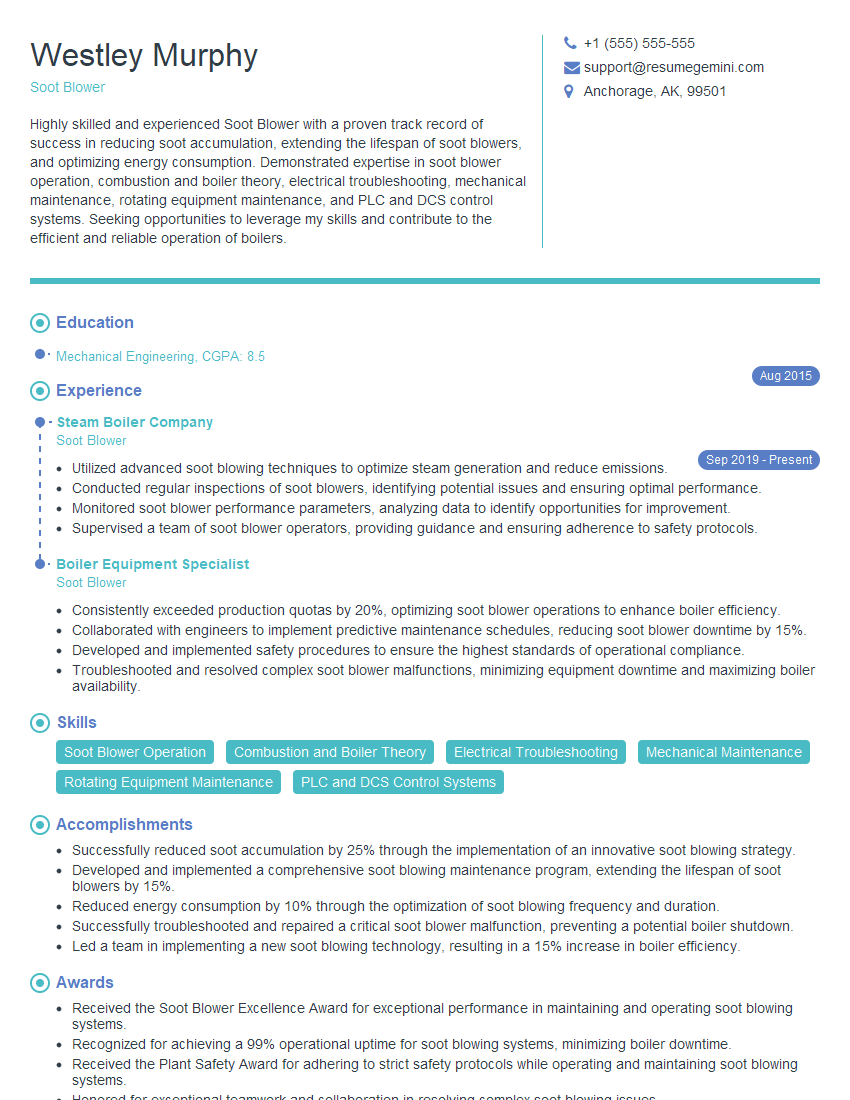

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Soot Blower

1. Explain the working principle of a soot blower?

Soot blowers are designed to remove soot and ash deposits from the surfaces of heat exchangers, boilers, and other industrial equipment. They work by directing a high-pressure stream of air, steam, or water at the deposits, dislodging them and carrying them away.

- Nozzles are strategically placed within the heat exchanger or boiler.

- When activated, the nozzles release a powerful jet of air or steam.

- This jet effectively dislodges soot and ash deposits from the surfaces.

- The dislodged deposits are then carried away by the flow of air or steam.

2. Describe the different types of soot blowers and their applications?

There are various types of soot blowers designed for specific applications. Here are some common types:

Steam soot blowers

- Utilize high-pressure steam to remove deposits.

- Suitable for high-temperature applications.

Air soot blowers

- Use compressed air to dislodge deposits.

- Often employed in low-temperature applications.

Water soot blowers

- Employ high-pressure water to remove deposits.

- Suitable for applications where steam or air cannot be used.

Sonic soot blowers

- Generate high-frequency sound waves to dislodge deposits.

- Effective in applications where traditional methods are not feasible.

3. How do you determine the optimal soot blowing frequency for a given application?

Determining the optimal soot blowing frequency involves considering several factors:

- Type of fuel being burned.

- Operating temperature of the equipment.

- Desired level of cleanliness.

- Availability of resources (e.g., steam, air, water).

By analyzing these factors and conducting site-specific tests, the optimal frequency can be established to maintain efficient operation and prevent excessive deposition.

4. What are the safety precautions that must be observed when operating soot blowers?

Operating soot blowers requires adherence to strict safety precautions:

- Wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and hearing protection.

- Ensure the equipment is properly grounded and isolated before servicing.

- Never operate soot blowers in the presence of flammable gases or materials.

- Follow manufacturer’s instructions for safe operation and maintenance.

- Regularly inspect and test soot blowers to ensure proper functioning.

5. How do you troubleshoot common soot blower problems?

Common soot blower problems and their troubleshooting steps include:

Clogged nozzles

- Check for blockages in the nozzles and clear them.

- Inspect the steam or air supply for any issues.

Insufficient pressure

- Verify the pressure of the steam or air supply.

- Check for leaks in the system.

Electrical faults

- Inspect electrical connections and wiring.

- Test the motor and solenoid valves.

6. What are the maintenance requirements for soot blowers?

Regular maintenance is crucial to ensure optimal performance and longevity of soot blowers:

- Inspect nozzles for wear or damage and replace as needed.

- Lubricate moving parts and check for any loose components.

- Clean and calibrate pressure gauges and other instruments.

- Perform operational testing to verify proper functioning.

- Follow manufacturer’s recommendations for scheduled maintenance.

7. How do you interpret soot blower performance data to optimize operations?

Soot blower performance data provides valuable insights for optimization:

- Analyze pressure readings to ensure sufficient force for effective soot removal.

- Monitor nozzle wear patterns to identify areas requiring attention.

- Track soot accumulation rates to adjust soot blowing frequency.

- Evaluate energy consumption to identify opportunities for efficiency improvements.

- Use data to make informed decisions and enhance overall system performance.

8. What are the latest advancements in soot blower technology?

Soot blower technology continues to evolve, offering improved efficiency and reliability:

- Advanced nozzle designs for better soot removal and reduced wear.

- Intelligent control systems for optimizing soot blowing cycles.

- Remote monitoring and diagnostics for proactive maintenance.

- Materials and coatings that enhance durability and corrosion resistance.

- Integration with plant automation systems for seamless operation.

9. How do you stay updated with the latest industry best practices for soot blower operations?

To stay abreast of industry best practices, I engage in the following:

- Attend industry conferences and workshops.

- Read technical journals and articles.

- Participate in online forums and discussions.

- Consult with equipment manufacturers and experts.

- Collaborate with colleagues and industry professionals.

10. What are your suggestions for improving the efficiency of a soot blowing system?

To enhance soot blowing efficiency, I recommend:

- Optimizing soot blowing frequency based on data analysis.

- Upgrading to advanced nozzle designs and materials.

- Implementing intelligent control systems for automated operation.

- Improving steam or air supply systems for consistent pressure.

- Conducting regular inspections and maintenance to prevent breakdowns.

- Training operators on proper soot blowing procedures.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Soot Blower.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Soot Blower‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Soot Blowers are essential for the efficient operation of boilers and other industrial equipment. Their primary function is to remove soot, ash, and other combustion byproducts from heat transfer surfaces, thereby reducing pressure drop, improving heat transfer, and increasing the overall efficiency of the system.

1. Operation, Maintenance, and Repair of Soot Blowers

Soot Blowers are complex machines that require regular maintenance and repairs to ensure optimal performance. Some of the key responsibilities of a Soot Blower include:

- Monitoring the performance of Soot Blowers and identifying any potential problems

- Performing routine maintenance tasks, such as cleaning, lubrication, and calibration

- Troubleshooting and repairing Soot Blowers when they malfunction

- Working with other maintenance personnel to ensure that Soot Blowers are properly integrated into the overall plant operation

2. Boiler and Heat Exchanger Cleaning

Soot Blowers are primarily used to clean boilers and heat exchangers. This involves removing soot, ash, and other combustion byproducts from the heat transfer surfaces. They use a variety of methods to do this, including steam, air, or water jets. Soot Blowers are essential for maintaining the efficiency of boilers and heat exchangers, as soot and ash can build up over time and reduce the amount of heat that is transferred.

- Using Soot Blowers to remove soot and ash from boilers and heat exchangers

- Inspecting boilers and heat exchangers for any damage or corrosion

- Working with other maintenance personnel to ensure that boilers and heat exchangers are operating properly

3. Safety and Compliance

Soot Blowers are operated under high pressure and can be hazardous if they are not properly maintained and operated. A qualified Soot Blower must be familiar with all applicable safety regulations and must follow all safety procedures.

- Following all safety regulations and procedures

- Wearing appropriate personal protective equipment

- Working in a safe manner and avoiding any unnecessary risks

- Reporting any safety concerns to the supervisor

Interview Tips

Preparing for a Soot Blower interview can be daunting, but with the right strategies, you can increase your chances of success. Here are a few tips:

1. Research the Company and the Position

Before you go on an interview, it’s important to do your research. This will help you understand the company’s culture, values, and goals. You should also learn as much as you can about the specific position you’re applying for. This will help you tailor your answers to the interviewer’s questions and demonstrate your interest in the job.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It’s a good idea to practice your answers to these questions ahead of time so that you can deliver them confidently and concisely.

3. Be Prepared to Talk About Your Experience and Skills

The interviewer will want to know about your experience and skills. Be prepared to talk about your experience operating and maintaining Soot Blowers. You should also be able to discuss your knowledge of boiler and heat exchanger cleaning. If you have any relevant certifications or training, be sure to mention them.

4. Dress Professionally and Arrive on Time

First impressions matter, so it’s important to dress professionally and arrive on time for your interview. This will show the interviewer that you’re serious about the position and that you respect their time.

5. Be Yourself and Be Confident

It’s important to be yourself and be confident during your interview. The interviewer will be able to tell if you’re being fake, so it’s best to just be yourself. Confidence is also key, as it will help you to answer the interviewer’s questions confidently and concisely.

Next Step:

Now that you’re armed with the knowledge of Soot Blower interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Soot Blower positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini